Fine dried noodle drying method

A dried noodle and high-temperature drying technology, which is applied in baking, dough processing, food science, etc., can solve the problems of easy cracks, waste, and stripping, and achieve the effect of not easy cracking, reducing waste, and improving the quality of dried noodles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0007] Specific embodiment 1: A drying method for dried noodles, which includes the step of preheating and keeping moisture. After the noodles are fixed by cold air, the noodles are preheated to keep moisture, and then the noodles are dried at high temperature and cooled with cold strips. .

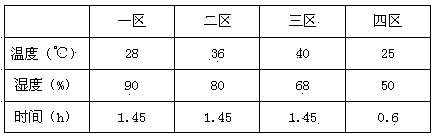

[0008] The specific method is as follows: Divide the drying workshop into four zones, the first zone is cold air fixed, the second zone preheats and keeps the tide, the third zone high temperature drying, the fourth zone cools down the noodles; The second zone is preheated to keep moisture, then enters the third zone for high-temperature drying, and finally enters the fourth zone to cool down the strip. The process parameters of each zone are shown in Table 1.

[0009] Table 1

[0010]

Example Embodiment

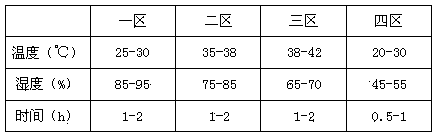

[0011] Specific implementation manner 2: In this implementation manner, the thickness of dried noodles is 1 mm and the width is 2-3 mm as an example. The process parameters are shown in Table 2:

[0012] Table 2

[0013]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap