Machine tool parallel synchronous motion mechanism

A technology of synchronous motion and machine tools, which is applied in the direction of metal processing machinery parts, metal processing equipment, feeding devices, etc., can solve the problems of inconvenient operation of CNC machine tools, high production costs, etc., and achieve the effect of improving labor productivity and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

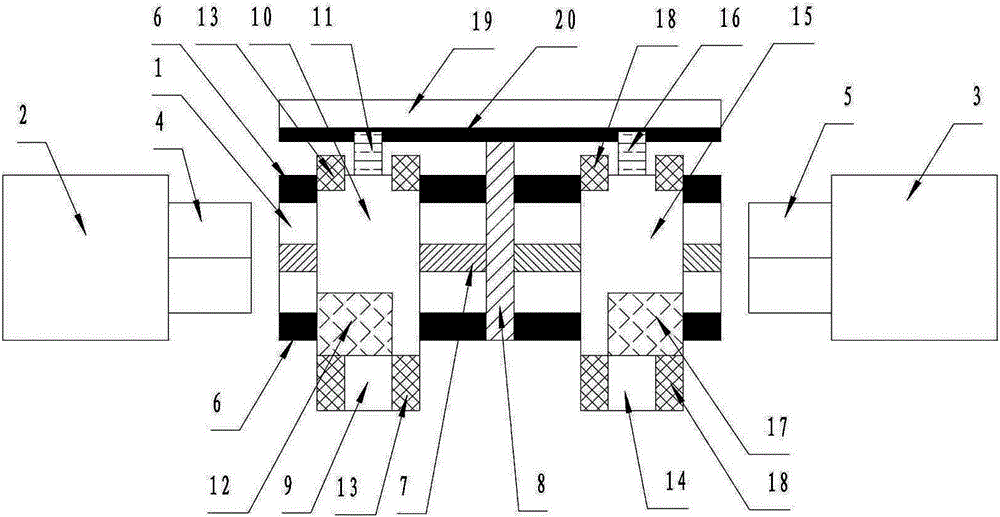

[0014] Such as figure 1 As shown, the parallel synchronous motion mechanism of the machine tool in this embodiment includes a machine bed 1, which is characterized in that one side of the machine bed 1 has a first headstock 2, and the other side of the machine bed 1 has a second Main shaft box 3, described first main shaft box 2 has first main shaft 4, and described second main shaft box 3 has second main shaft 5, and described first main shaft 4 is arranged opposite to second main shaft 5, and described first main shaft 4 There are longitudinal guide rails 6 on both sides of the machine bed 1 between the second main shaft 5, the longitudinal guide rails 6 are parallel to the first main shaft 4 and the second main shaft 5, and the middle part of the machine bed 1 has a longitudinal screw rod 7, so The machine tool bed 1 is provided with a transverse screw rod 8 arranged in a cross shape with the longitudinal screw rod 7, and there are respectively a first assembly and a second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com