Steel wire rope guide wheel for warp knitting machine

A wire rope and warp knitting machine technology, applied in warp knitting, textiles, papermaking, knitting, etc., can solve the problems of affecting tension, large gaps, and uncompact structures, so as to ensure work progress, good quality, and uniform products Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

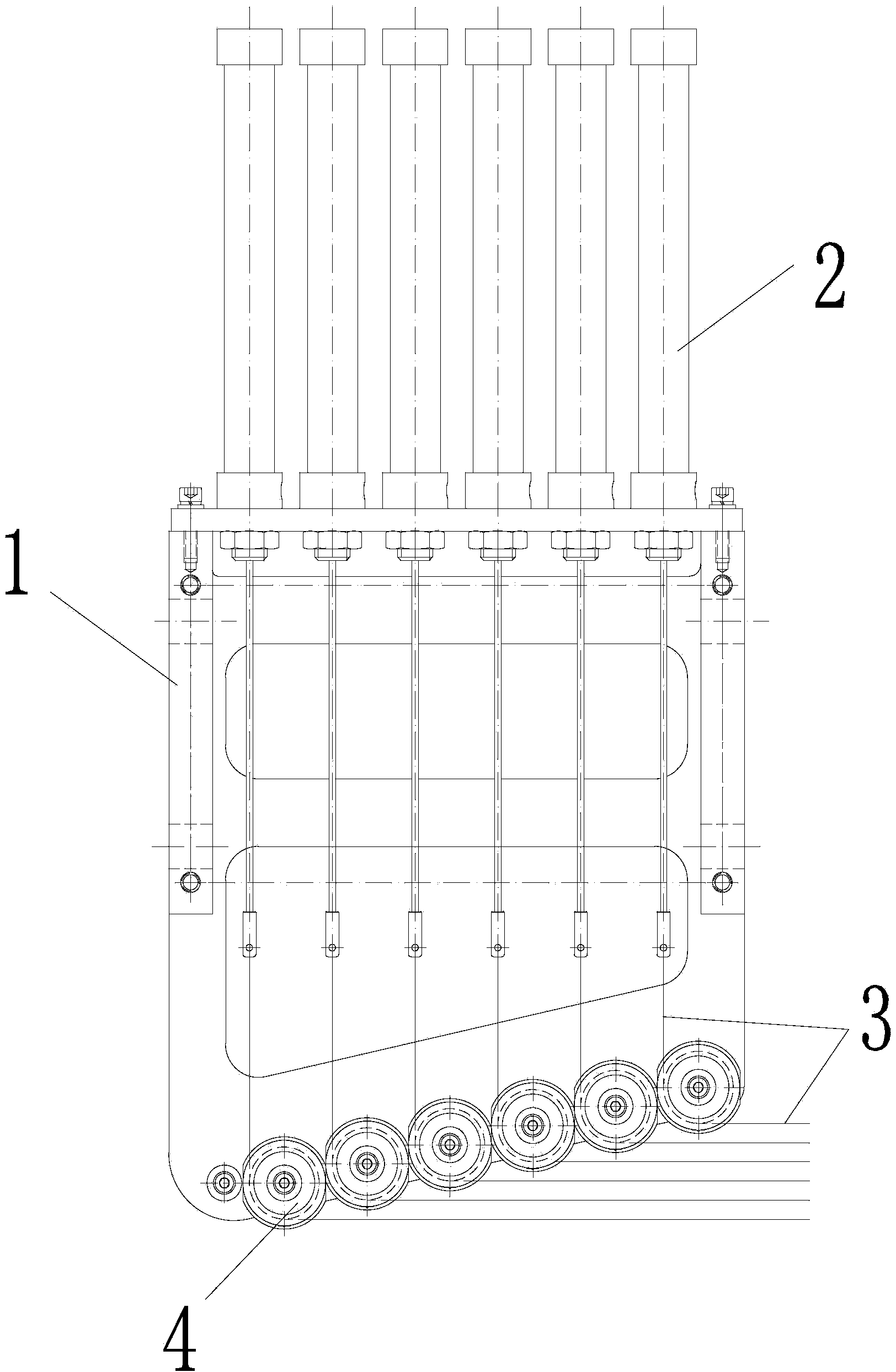

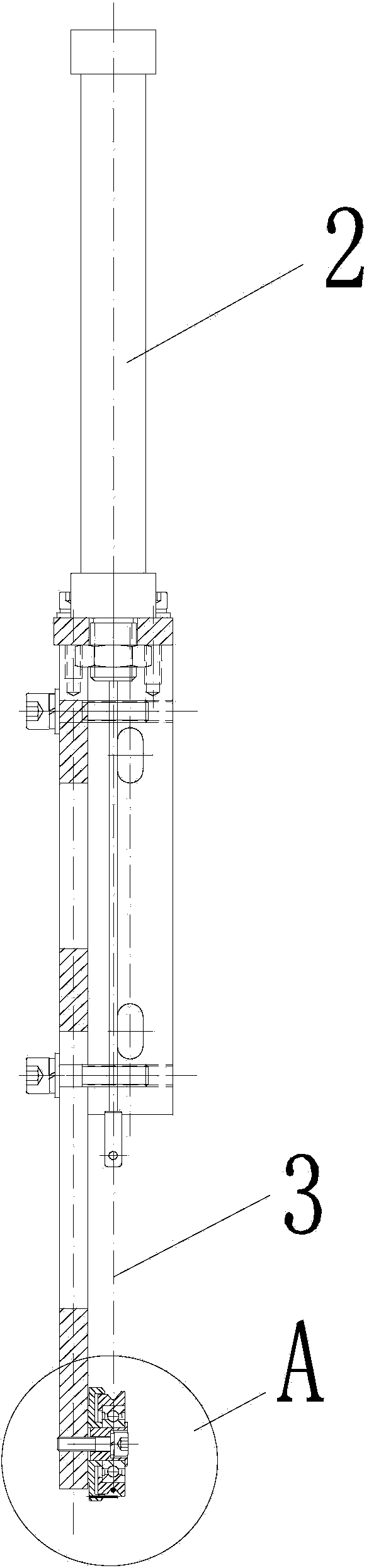

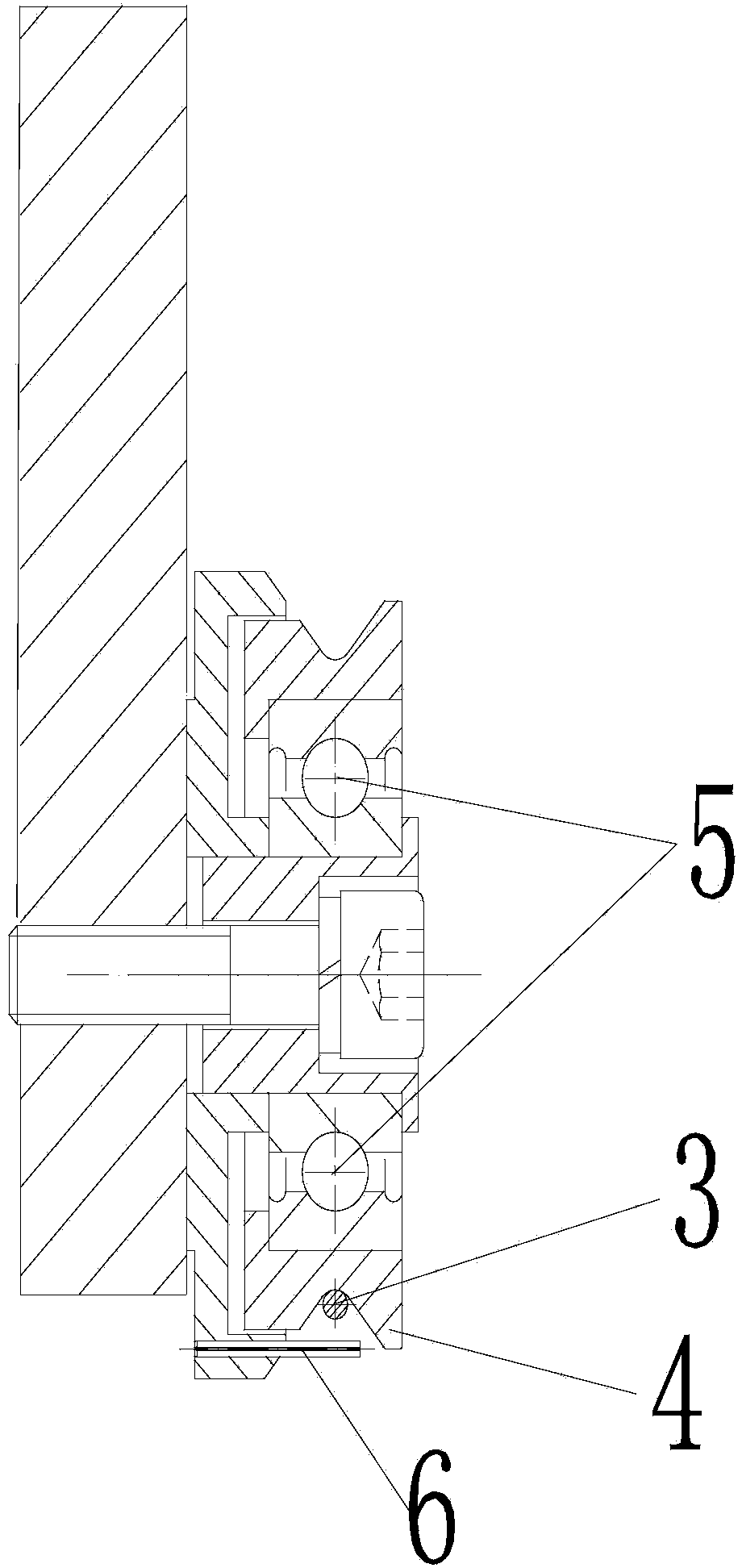

[0015] Such as figure 1 , figure 2 The shown wire rope guide wheel for warp knitting machine includes a bracket 1, a gas spring 2, a wire rope 3, and a wire rope guide wheel 4. The gas spring 2 is fixed on the bracket 1, and the gas spring 2 The lower end of the wire rope 3 is tensioned, the wire rope 3 passes through the wire rope guide wheel 4 and moves in coordination, the gap between the two adjacent wire rope guide wheels 4 is smaller than the diameter of the wire rope 3, The angle between the axis line of the wire rope guide wheel 4 and the horizontal line is 12°, the upper and lower parts of the wire rope guide wheel 4 are provided with two deep groove ball bearings 5, and the wire rope 3 passes through the two deep grooves. The ball bearing 5 is provided with a pipe pin 6 on the left side of the wire rope guide wheel 4 at the leftmost end. The diameter of the wire rope 3 is 1.5 mm. The gap between two adjacent wire rope guide wheels 4 is 0.9 mm. The number of gas spr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap