A kind of preparation method of high-quality dalteparin sodium

The technology of high-quality dalteparin sodium and heparin sodium is applied in the preparation of medicinal chemicals and the field of high-quality dalteparin sodium, which can solve the problems of inability to realize industrialized production, complicated operation steps, long purification cycle, etc., and achieves low cost, The effect of improving heparin yield and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

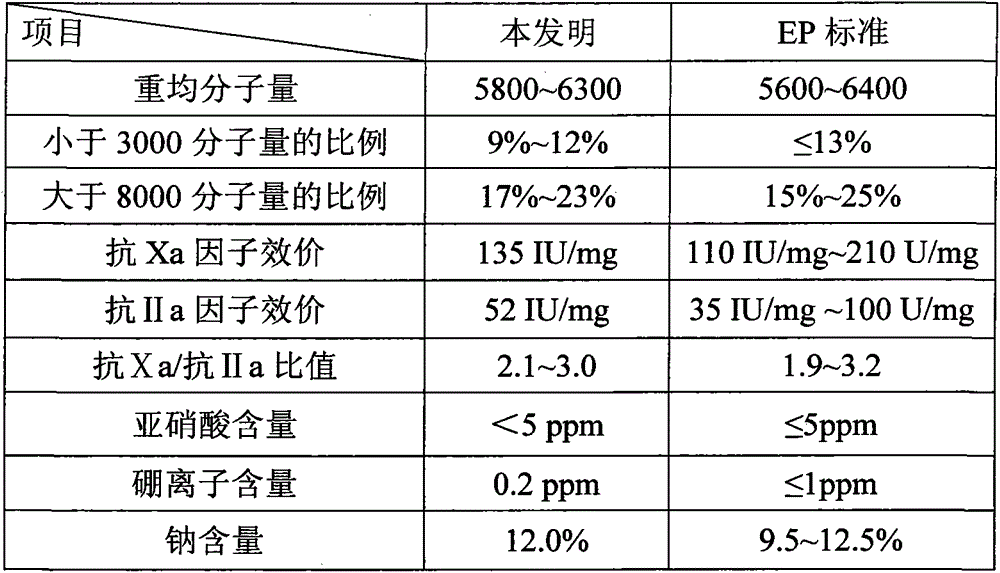

Image

Examples

Embodiment 1

[0034] A preparation method of high-quality dalteparin sodium: ①Add 30kg of high-quality heparin sodium to the reaction tank, then add 100L of water for injection to make it completely dissolved, adjust the pH to 6.0 with 1mol / L acetic acid, and control the temperature at 70 ℃, add 150 g of sodium nitrite, stir and react at room temperature for 5 hours to obtain a heparin degradation solution. ② Add an appropriate amount of sodium hydroxide solution to the heparin degradation solution to adjust the pH of the system to 8 to terminate the degradation reaction, and then add 300 g of sodium borohydride for reduction for 2 hours. After the reaction is completed, adjust the pH of the system to 7.0 with an appropriate amount of sodium hydroxide solution, and discharge. That is, the reducing solution is obtained. 3. Add 0.5 times the volume of alcohol to the reducing solution in step 2. according to the ratio of weight (kg) of the reducing solution: volume of alcohol (L)=1:0.5, stir a...

Embodiment 2

[0036]A preparation method of high-quality dalteparin sodium: 1. Add 30 kg of heparin sodium high-quality goods accurately weighed into a reaction tank, then add 100 L of water for injection, and stir at room temperature until it is completely dissolved to obtain a solution; use 1 mol / L of acetic acid to adjust the pH to 3.5, the temperature was controlled at 70° C., 170 g of sodium nitrite was added, and the mixture was stirred and reacted at room temperature for 4.5 hours to obtain a heparin degradation solution. ② Add an appropriate amount of potassium hydroxide solution to the above-mentioned heparin degradation solution to adjust the pH of the system to 8.5 to terminate the degradation reaction, then add 320 g of sodium borohydride for reduction for 2 hours, and after the reaction is completed, adjust the pH of the system to 6.2 with an appropriate amount of potassium hydroxide solution to obtain reducing solution. 3. Add 0.5 times the volume of alcohol to the reducing so...

Embodiment 3

[0038] A preparation method of high-quality dalteparin sodium: 1. Add 30 kg of heparin sodium high-quality goods accurately weighed into a reaction tank, then add 100 L of water for injection, and stir at room temperature until it is completely dissolved to obtain a solution; use 1 mol / L of acetic acid to adjust the pH to 2.5, the temperature was controlled at 70° C., 200 g of sodium nitrite was added, and the mixture was stirred and reacted at room temperature for 4.5 hours to obtain a heparin degradation solution. ②Add an appropriate amount of sodium hydroxide solution to the above-mentioned heparin degradation solution to adjust the pH of the system to 9.5 to terminate the degradation reaction, then add 400 g of sodium borohydride for reduction for 2 hours, and after the reaction is completed, adjust the pH of the system to 6.8 with an appropriate amount of sodium hydroxide solution to obtain reducing solution. ③Add 18L of alcohol to the reducing solution in step ② accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com