Method To Make Curved Tubular Element And Curved Tubular Element Thus Obtained

A technology for bending pipes and bending parts, applied in the direction of pipe elements, pipes/pipe joints/fittings, elbows, etc., capable of solving complex and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

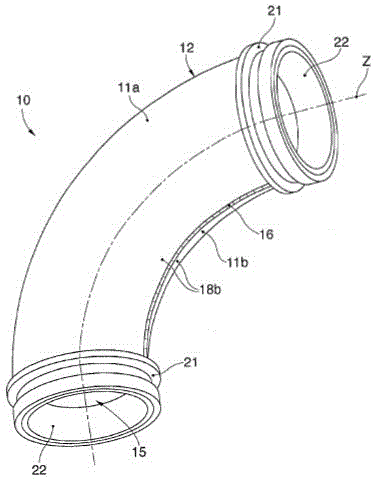

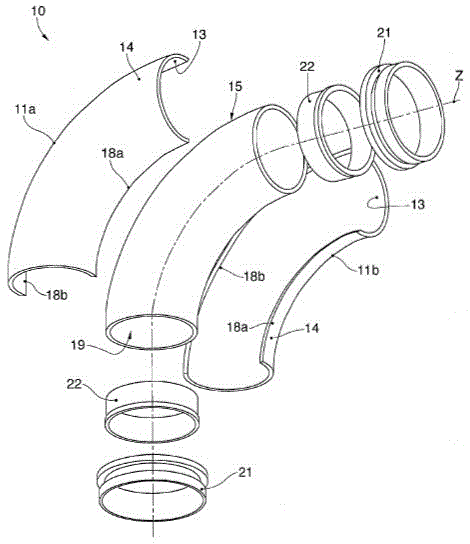

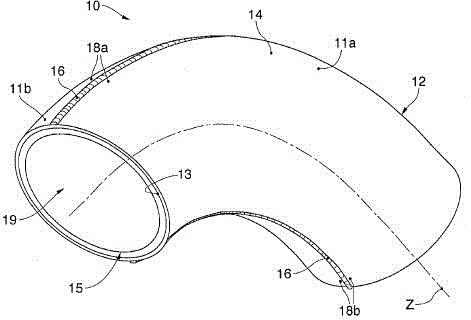

[0039] refer to figure 1 , in this embodiment, the curved pipe 10 for transporting abrasive material (eg concrete or the like) according to the present invention comprises two parts 11a and 11b (or shells). When connected and fixed to each other, the two parts 11a and 11b form a first outer part 12 having a tubular cross-section and having a curved extension along a bending axis Z (circle arc in this embodiment), a second inner A curved part or anti-wear insert 15 is provided within this first outer part 12 .

[0040] In particular, each part 11 a , 11 b has a cross section that is a corresponding portion of the tubular section of the first outer part 12 and extends longitudinally along the bending axis Z. The two parts 11a and 11b are connected to each other along respective longitudinal edges 18a, 18b by welding to obtain respective weld seams 16 .

[0041]The parts 11a and 11b can be welded by a welding method using oxyacetylene, electrodes, submerged arc welding (of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com