Enhanced oil recovery methods for producing oil from heavy oil fields

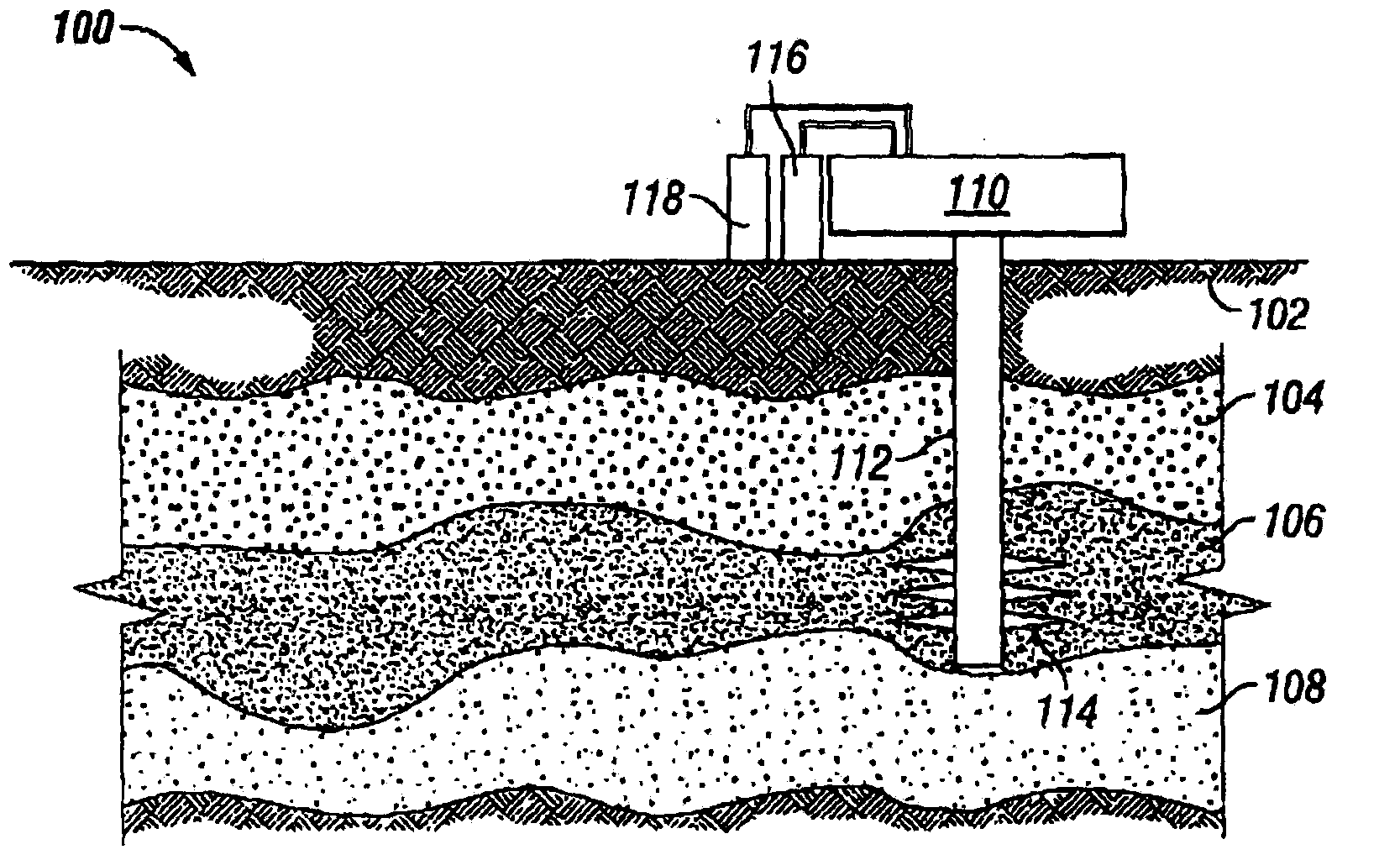

A technology for flowing oil and formation, which is applied in chemical instruments and methods, dehydration/demulsification by chemical methods, processing of hydrocarbon oil, etc., and can solve problems such as inability to effectively exploit oil reservoirs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

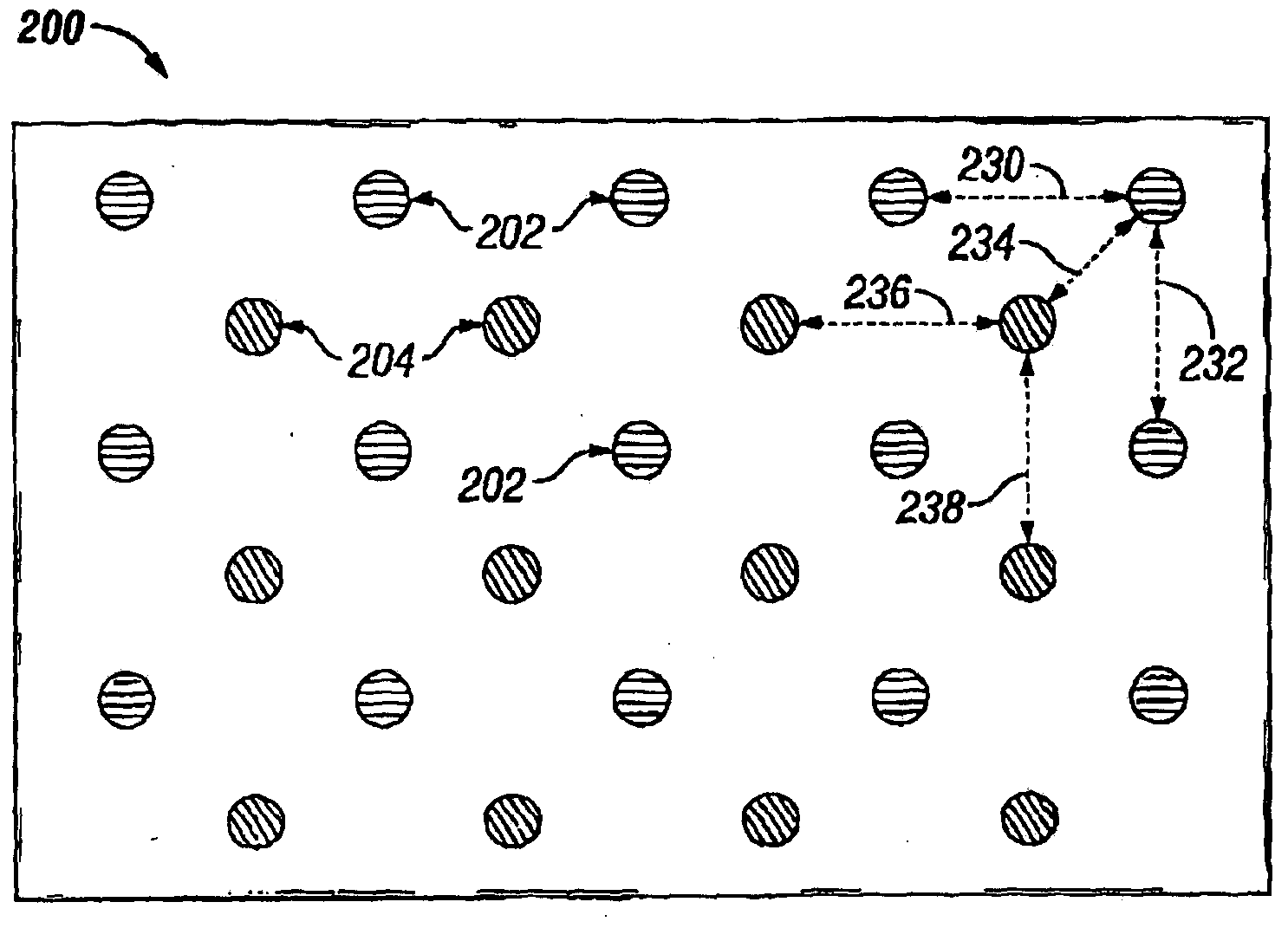

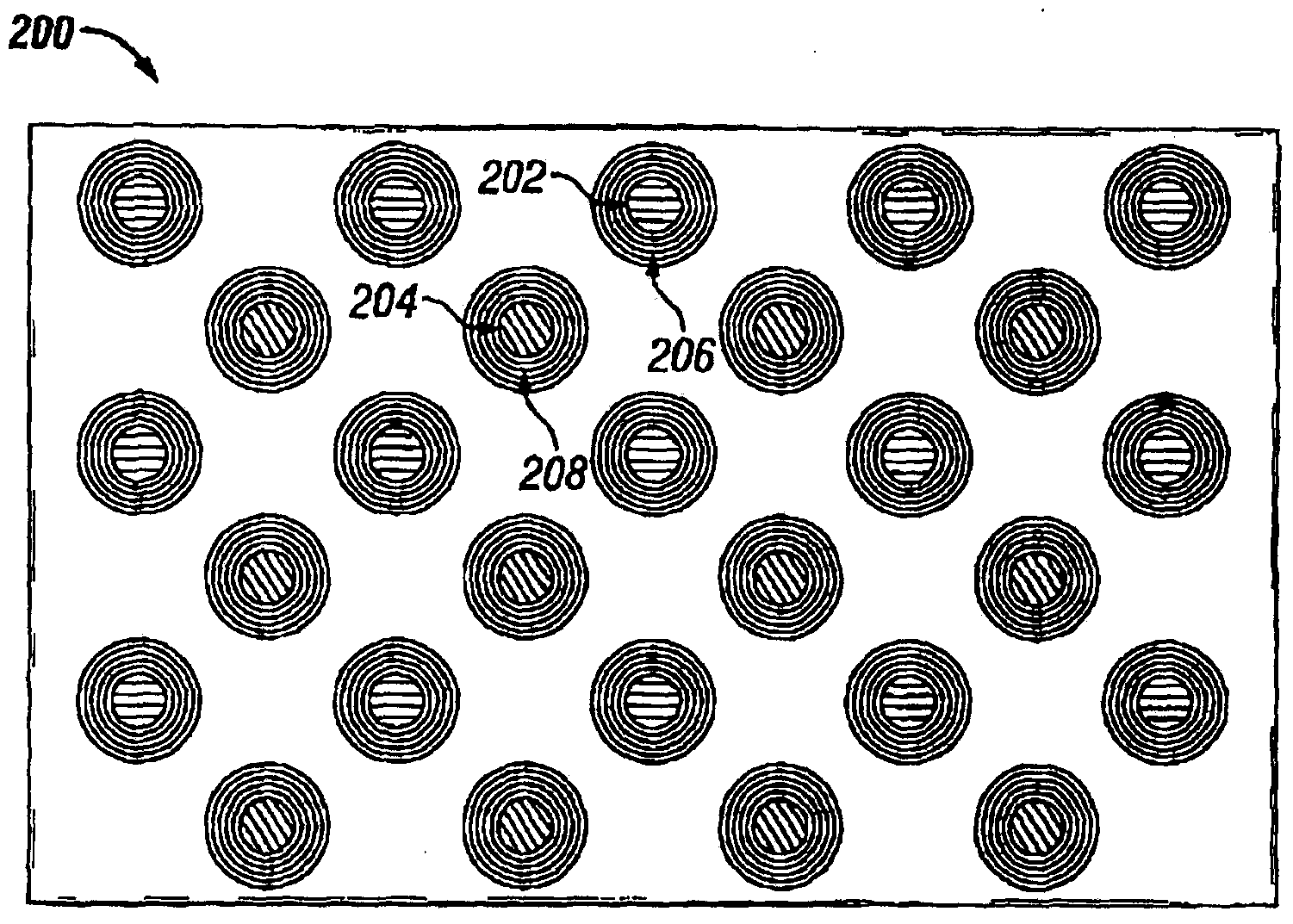

Method used

Image

Examples

Embodiment Construction

[0029] To facilitate a better understanding of oil solubilization, the following examples are given. It will be appreciated that the following examples should in no way be construed as limiting or limiting the scope of the invention. Referring briefly to Figures 3a and 3b, shown are exemplary graphs showing, respectively, how the viscosity of an oil in general varies with 2 ) solvent interaction is reduced. The first graph shown in Figure 3a depicts testing of oil taken from the Camp Hill, Texas, USA reservoir. As shown, the approximate temperature of the oil in the reservoir is about 20°C, and when the volume fraction of carbon disulfide is 0, it shows a viscosity of about 1000cP. However, as the volume fraction of carbon disulfide increases, the viscosity of the oil gradually decreases. For example, at 0.2 (20%) carbon disulfide volume fraction, the oil exhibits a viscosity of about 30-40 cP at 20°C, which makes the oil quite flowable and easier to extract.

[0030] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com