A waste water treatment process and device for power plant boiler make-up water production

A wastewater treatment and make-up water technology, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of high cost of wastewater recycling and treatment, unfavorable economic benefits, and low wastewater recovery rate To achieve the effect of improving the utilization rate of water resources, increasing the income of enterprises, and saving the occupied area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

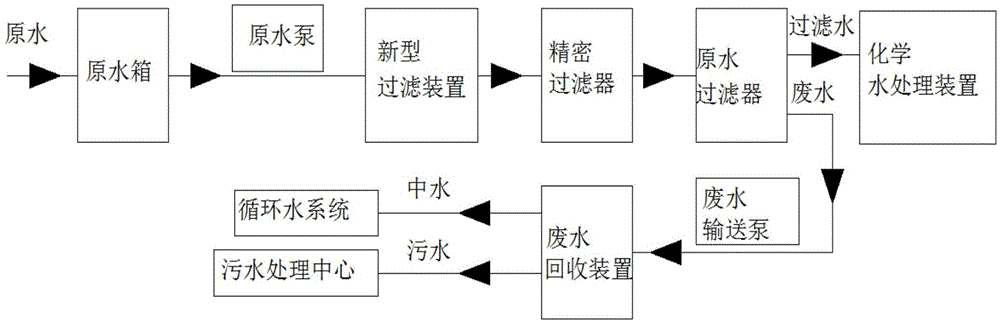

[0025] A waste water treatment process in the production of power plant boiler make-up water, such as figure 1 shown, including the following steps:

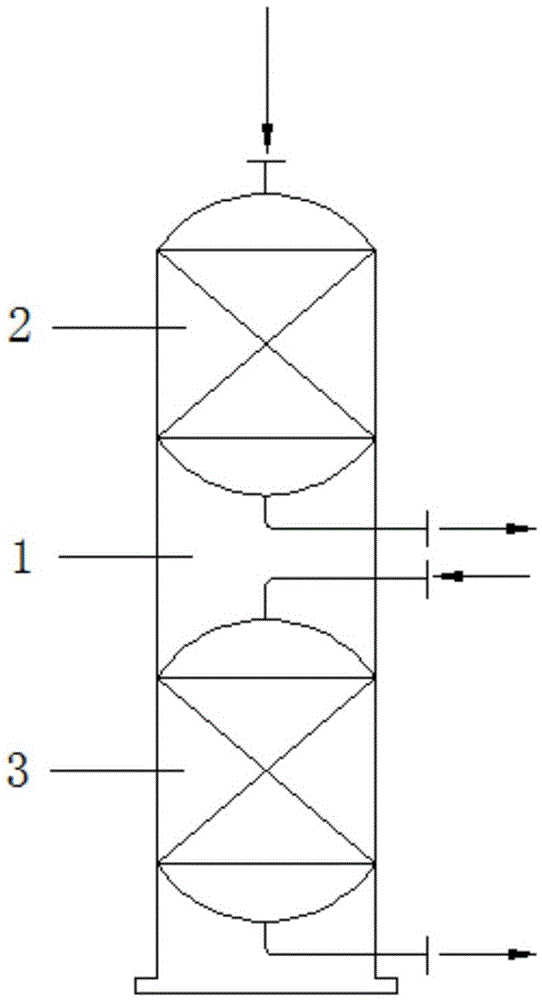

[0026] (1) The raw water produced during the production process of boiler feed water in the power plant enters the raw water tank, where the temperature of the raw water is 10°C and the flow rate is 266m 3 / h, the raw water is pumped into the new filter device 1 and the precision filter in turn, and the first-level filtration and the second-level filtration are carried out respectively. and colloid; Among them, after the first stage filtration by the new filter device 1, the water quality SDI value is 4, and the total iron content is 0.1mg / L;

[0027] (2) The filtered water after continuous primary filtration and secondary filtration enters the raw water filter, and multi-stage membrane separation is performed in the raw water filter to separate the filtered water through the filter membrane and the waste water that has not pas...

Embodiment 2

[0033] (1) The raw water produced during the production process of boiler feed water in the power plant enters the raw water tank, where the temperature of the raw water is 10°C and the flow rate is 266m 3 / h, the raw water is pumped into the new filter device 1 and the precision filter in turn, and the first-level filtration and the second-level filtration are carried out respectively. and colloid; Among them, after the first-stage filtration by the new filter device 1, the water quality SDI value is 1.6, and the total iron content is 0.02mg / L;

[0034] (2) The filtered water after continuous primary filtration and secondary filtration enters the raw water filter, and multi-stage membrane separation is performed in the raw water filter to separate the filtered water through the filter membrane and the waste water that has not passed through the filter membrane, The separated filtered water enters the chemical water treatment process, after the ion exchange process removes the...

Embodiment 3

[0038] (1) The raw water produced during the production process of boiler feed water in the power plant enters the raw water tank, where the temperature of the raw water is 10°C and the flow rate is 266m 3 / h, the raw water is pumped into the new filter device 1 and the precision filter in turn, and the first-level filtration and the second-level filtration are carried out respectively. and colloid; Among them, after the first stage filtration by the new filter device 1, the water quality SDI value is 2.4, and the total iron content is 0.05mg / L;

[0039] (2) The filtered water after continuous primary filtration and secondary filtration enters the raw water filter, and multi-stage membrane separation is performed in the raw water filter to separate the filtered water through the filter membrane and the waste water that has not passed through the filter membrane, The separated filtered water enters the chemical water treatment process, after the ion exchange process removes the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com