Fixing device and image forming device

A technology of fixing belt and fixing roller, which is applied in the direction of electric recording process applying charge pattern, equipment for applying electric recording process of charge pattern, electric recording technique, etc. Slow, long warm-up time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

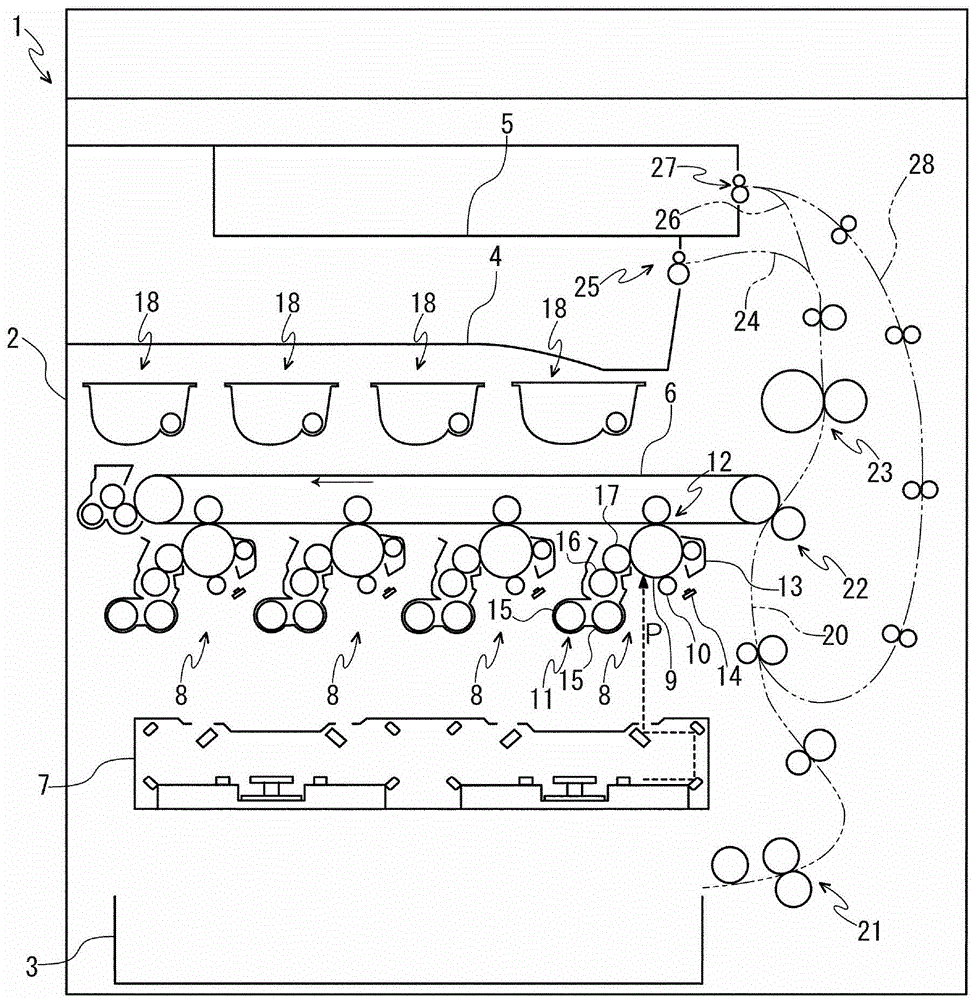

[0022] First, refer to figure 1 The overall configuration of the printer 1 (image forming apparatus) will be described. figure 1 It is a schematic configuration diagram showing a printer according to an embodiment of the present invention.

[0023] The printer 1 has a box-shaped printer main body 2. A paper feed cassette for storing paper as a recording body is provided on the lower part of the printer main body 2. A first paper output tray 4 is provided on the upper part of the printer main body 2. A second output tray 5 is provided above the paper tray 4 .

[0024] Inside the printer main body 2 , an intermediate transfer belt 6 (image carrier) is disposed between a plurality of rollers, and an exposure unit 7 constituted by a laser scanning unit (LSU) is disposed below the intermediate transfer belt 6 . Four image forming units 8 are provided on the lower side of the intermediate transfer belt 6 according to the color of toner (developer) (for example, four colors of ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com