An all-terrain crane and its center of gravity monitoring device and method

A monitoring device and crane technology, applied in cranes and other directions, can solve the problems of time-consuming, offset of the center of gravity, uneven distribution of axle loads, etc., and achieve the effect of reducing repair and maintenance costs and improving service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

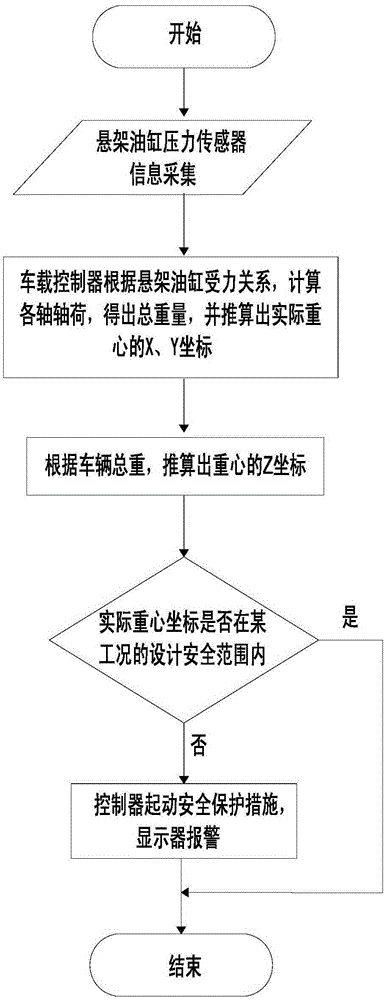

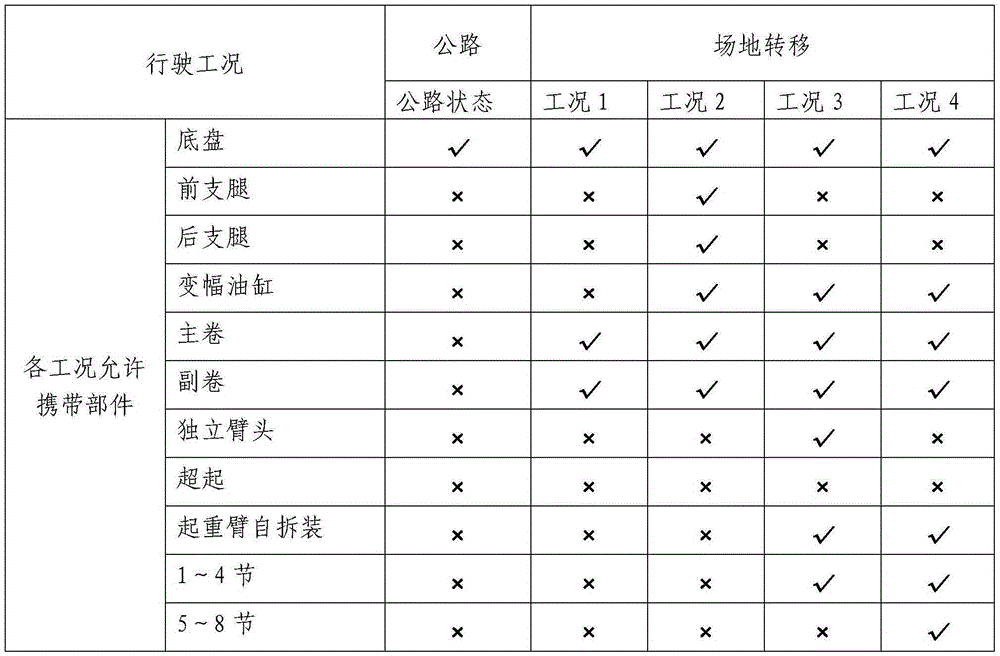

[0037] The core of the present invention is to provide a center of gravity monitoring device for an all-terrain crane to monitor and control the center of gravity of the all-terrain crane, thereby improving its stability and safety under different working conditions.

[0038] The present embodiment will be described in detail below in conjunction with the accompanying drawings.

[0039] Without loss of generality, the present embodiment takes an all-terrain crane having the characteristics of both a truck crane and a rough-terrain crane as the main body for detailed description.

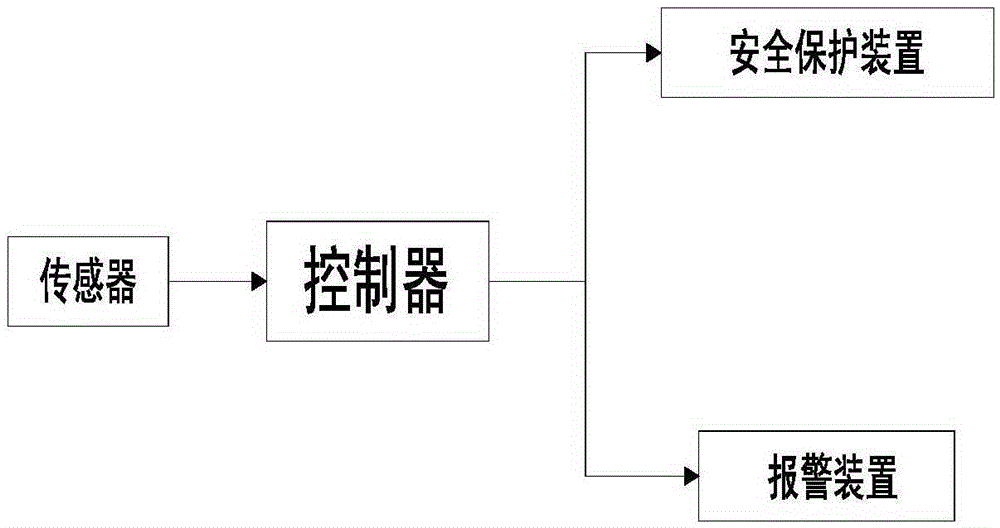

[0040] Please refer to figure 1 , figure 1 It is the control schematic diagram of the center of gravity monitoring device of the all-terrain crane provided by the present invention.

[0041] As shown in the figure, in a specific embodiment, the center of gravity monitoring device for an all-terrain crane provided by the present invention is mainly composed of a sensor, a controller, a safety protec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com