Protruding point of package substrate and manufacturing method of protruding point

A technology for packaging substrates and manufacturing methods, which is applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device parts, semiconductor devices, etc. Difficult control, great impact on assembly, etc., to achieve good welding performance, good consistency, and increased capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

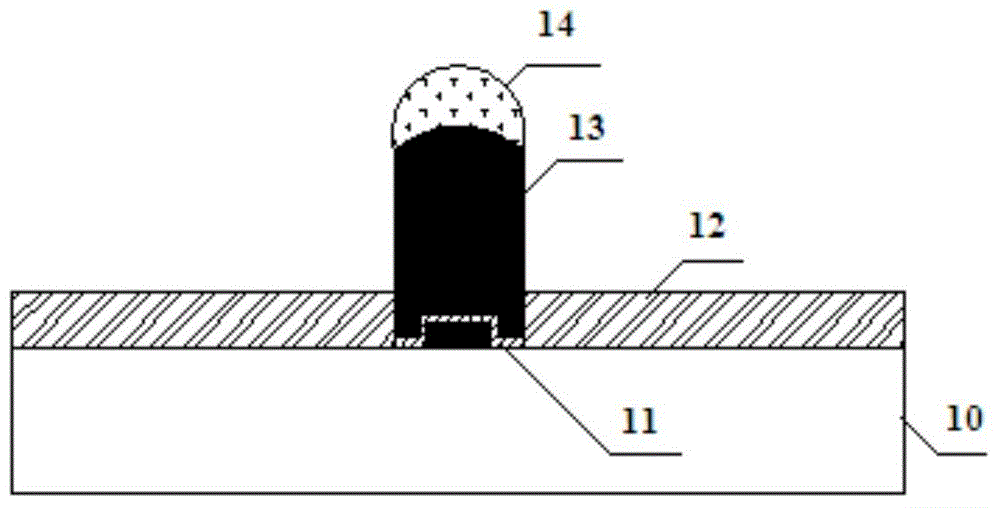

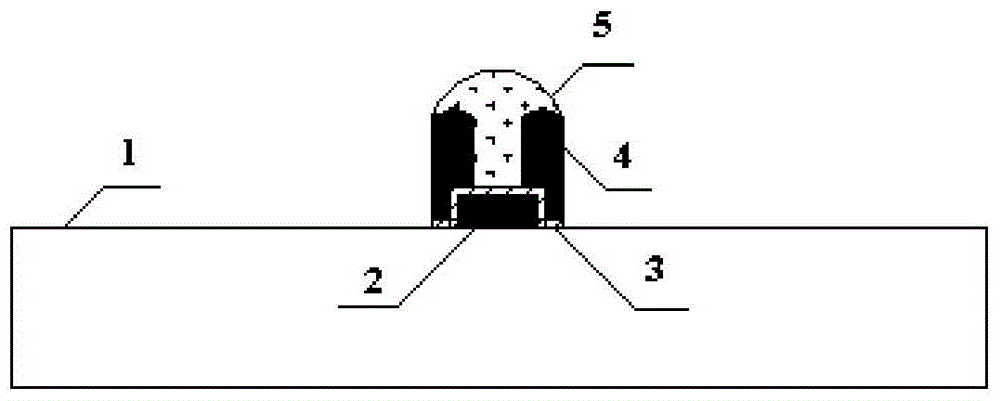

[0023] see figure 2 , the embodiment of the present invention provides a bump, including: a bump body 4; the bump body 4 is a cylindrical structure; the bump body 4 is located on the electroless copper plating layer 3 above the inner circuit 2. The solder 5 with a low melting point is filled in the inner cavity of the bump body 4, thereby increasing the amount of the solder 5 and ensuring the stability of soldering. On the other hand, when the low melting point solder 5 is filled in the inner cavity of the bump body 4, it is constrained by the bump wall and the surface tension of the fluid solder itself to form a stable and regular spherical surface, thereby ensuring the smoothness of the bump body 4. Consistency in height and shape is good.

[0024] The center of the bottom of the bump body 4 coincides with the center line of the inner layer circuit; thereby ensuring that the bump body 4 can form a stable connection with the inner layer circuit 2 from the side and upper sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com