Ag alloy film to be used as reflecting film and/or transmitting film or as electrical wiring and/or electrode, ag alloy sputtering target, and ag alloy filler

A technology of electrical wiring and alloy film, applied in the field of Ag alloy film used for reflective film and/or transmissive film, or used for electrical wiring and/or electrode, and Ag alloy sputtering target and Ag alloy filler, can solve the problem of Excellent durability, excellent adhesion, and excellent productivity are achieved without problems such as cloudiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] On a glass substrate (Dow Corning's non-alkali glass #1737, diameter: 50 mm, thickness: 0.7 mm), a pure Ag film or an Ag film having the composition shown in Table 1 was formed by sputtering using a DC magnetron sputtering device. Alloy films (both film thicknesses are 100nm, single-layer film) are formed. The film-forming conditions at this time are as follows.

[0057] (film forming conditions)

[0058] Substrate temperature: room temperature

[0059] Film forming power: DC15W / cm 2

[0060] Ar pressure: 1~3mTorr

[0061] Electrode spacing: 55mm

[0062] Film forming speed: 7.0~8.0nm / sec

[0063] Ultimate vacuum degree: 1.0×10 -5 Below Torr

[0064] In addition, in the above film formation, as a sputtering target, a pure Ag target (when forming a pure Ag film) or an Ag alloy having the same composition as the film composition shown in the following Table 1 prepared by a vacuum melting method was used. Sputtering targets (targets all 4 inches in diameter). In ...

Embodiment 2

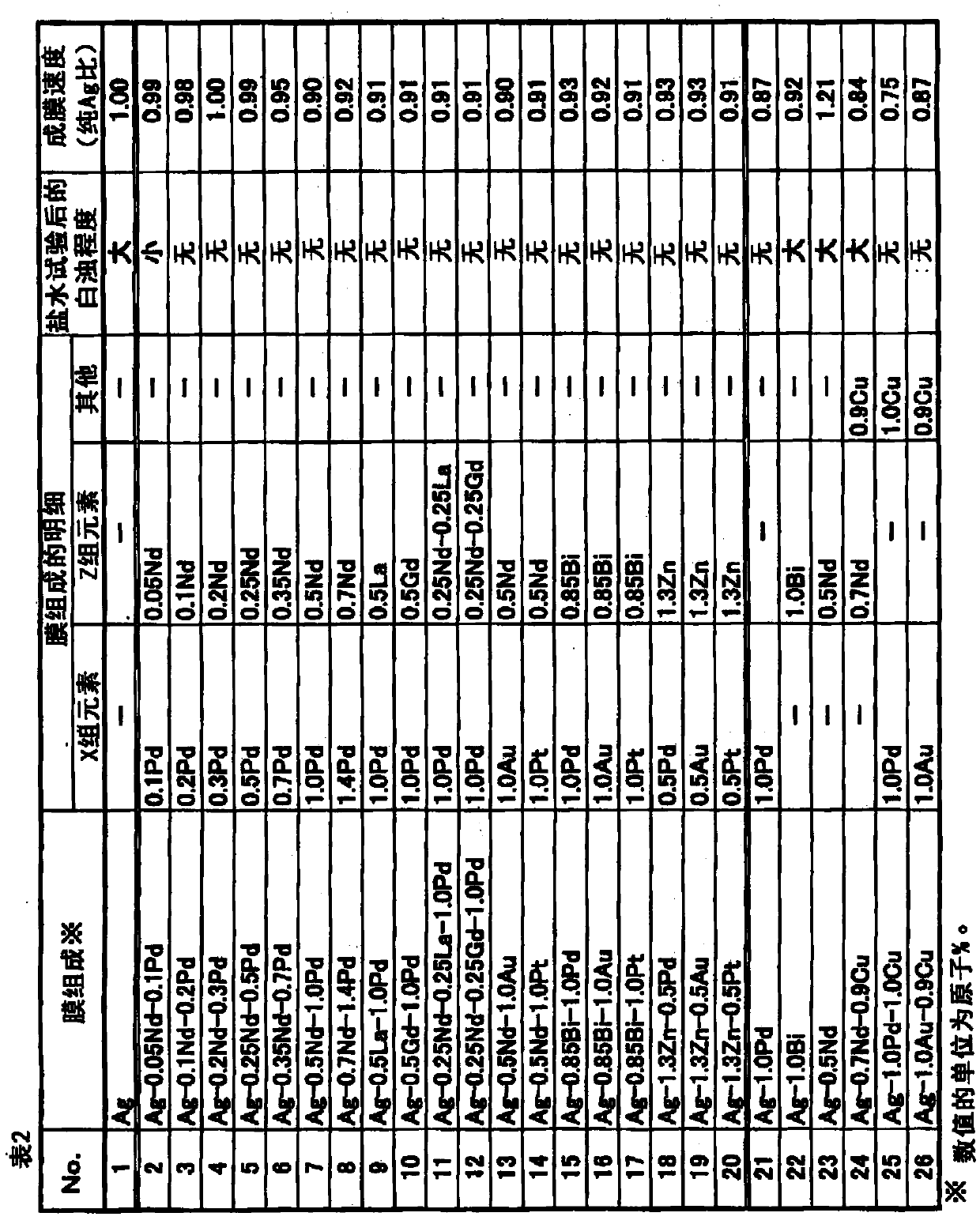

[0083] On a glass substrate (Dow Corning's non-alkali glass #1737, diameter: 50 mm, thickness: 0.7 mm), use a DC magnetron sputtering device to form a pure Ag film or an Ag alloy with the composition shown in Table 2 by sputtering. Films (both film thicknesses are 100nm, single-layer film) are formed into films. The film-forming conditions at this time are as follows.

[0084] (film forming conditions)

[0085] Substrate temperature: room temperature

[0086] Film forming power: DC2.55W / cm 2

[0087] Ar gas pressure: 1.9Pa

[0088] Electrode spacing: 120mm

[0089] Ultimate vacuum degree: 4.0×10 -5 Below Pa

[0090] In addition, in the above film formation, as the sputtering target, a pure Ag target (in the case of forming a pure Ag film) or an Ag alloy having the same composition as the film composition shown in Table 2 below prepared by a vacuum melting method was used. Sputtering targets (targets all 4 inches in diameter). In addition, in No. 15-17 and 22 of Table ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com