Household intelligent wine making machine

A wine and brewing machine technology, which is applied in the preparation of wine, the preparation of alcoholic beverages, biochemical equipment and methods, etc., can solve the problems of affecting fermentation, bacterial contamination, and poor filtration effect, so as to ensure quality and prevent oxidation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0016] Example 1

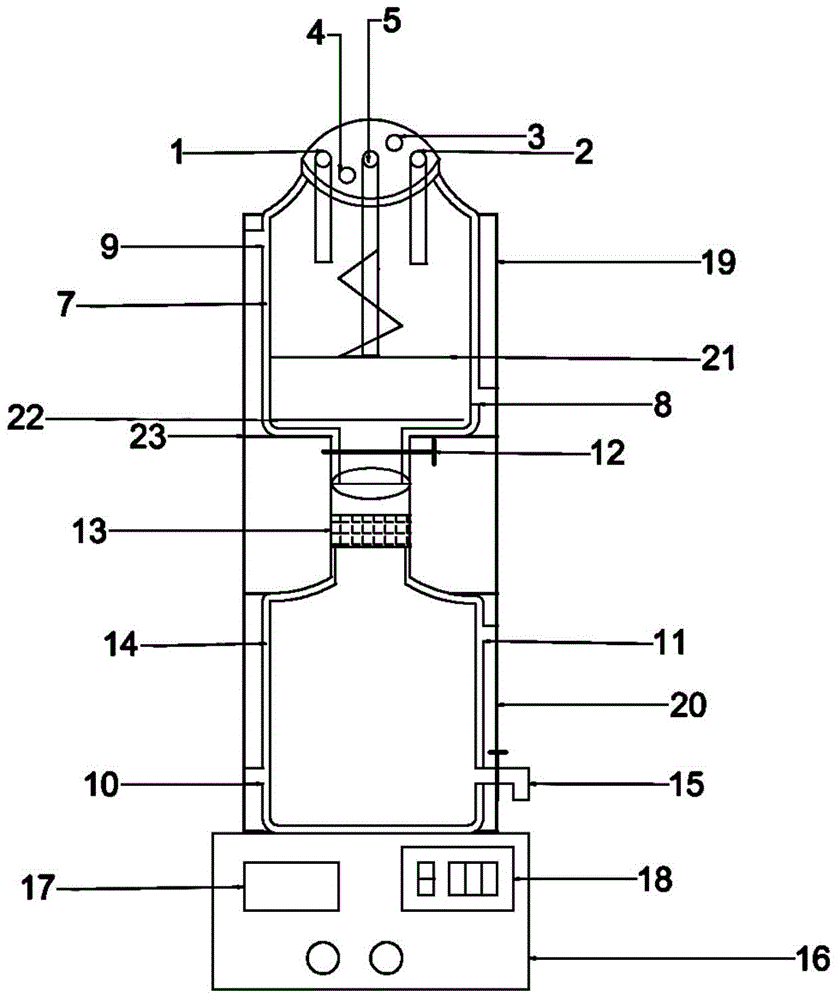

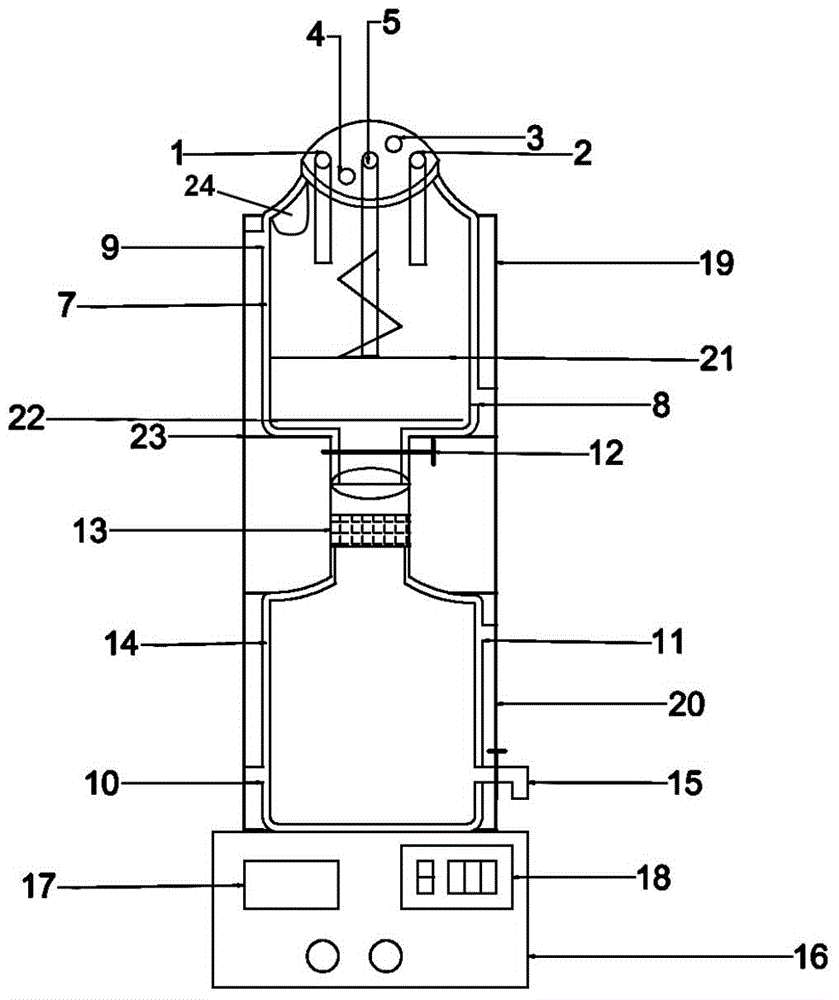

[0017] Such as figure 1 As shown, it mainly includes a fermentation tank 7, a storage tank 14, a measuring instrument, and a control cabinet 16. Among them, the measuring instrument includes a temperature sensor 1 and an alcohol sensor 2. The fermentation tank is provided with an air inlet and an air outlet, and the air inlet 4 and the air outlet 3 are provided with a bacterial filter. The upper part of the fermenter has a cover, and the temperature sensor 1 passes through the cover and extends to the bottom of the fermenter. One end of the motor extends into the fermenter body through the connecting rod and is connected with a cap plate. A pressure cap plate 21 is arranged in the fermentation tank body, and the pressure cap plate is connected with the motor through a connecting rod. The joint between the pressure cap plate 21 and the circular motor 5 and the tank cover uses a silicone gasket. Under the control of the motor, the pressure cap plate moves up a...

Example Embodiment

[0023] Example 2

[0024] In this embodiment, there is a housing with a stopper inside the housing, the fermentation tank is detachably fixed in the housing above the stopper, and the storage tank is fixed in the housing below the stopper. Putting the fermentation tank and the storage tank into the upper and lower parts of the shell is convenient to realize the separation of the fermentation tank and the storage tank. The storage tank can be integrally fixed under the casing, or can be put into the casing from the upper end, which can be realized by the shape design of the casing, the stopper and the storage tank. Or alternatively, a movable door is provided under the casing, so that the storage tank can be put into the casing from below. Still alternatively, the blocking portion can be detachably coupled to the housing.

Example Embodiment

[0025] Example 3

[0026] In this embodiment, it includes a first shell for accommodating and fixing the fermentation tank and a second shell for accommodating and fixing the storage tank, and the first shell and the second shell are detachably coupled. Therefore, after a fermentation process is completed, the upper fermentation tank can be removed, replaced with new grapes, and a new fermentation process can be carried out. The two fermentation processes can be carried out simultaneously.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap