Lens and light emitting module adopting same

A technology of lenses and light-emitting components, which is applied in the direction of light sources, point light sources, and components of lighting devices, etc. It can solve problems such as small light-emitting angles, uneven light intensity, and the inability of light-emitting modules to achieve light-emitting effects, and achieve large light-emitting angles. , the effect of uniform light intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

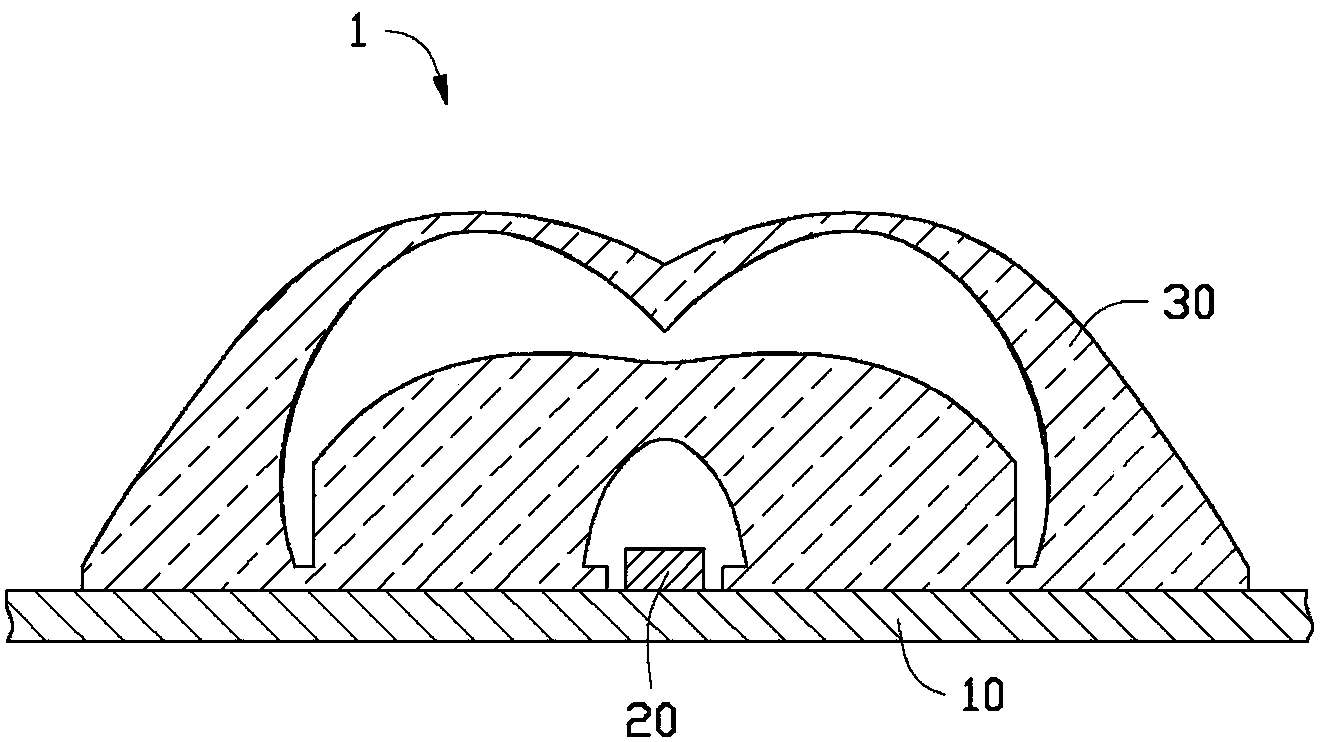

[0016] see figure 1 The light-emitting module 1 of the present invention includes a substrate 10 , a light-emitting element 20 disposed on the substrate 10 , and a lens 30 disposed on the substrate 10 and covering the light-emitting element 20 . The light emitted by the light emitting element 20 is diffused by the lens 30 and then emitted uniformly.

[0017] The substrate 10 is an insulating board, which can be made of ceramic (Ceramic), silicon (Si), sapphire (Sapphire), silicon carbide (SiC) and other materials.

[0018] In this embodiment, the light emitting element 20 is a light emitting diode. Certainly, in other embodiments, the light-emitting element 20 may also be other light-emitting bodies such as laser diodes.

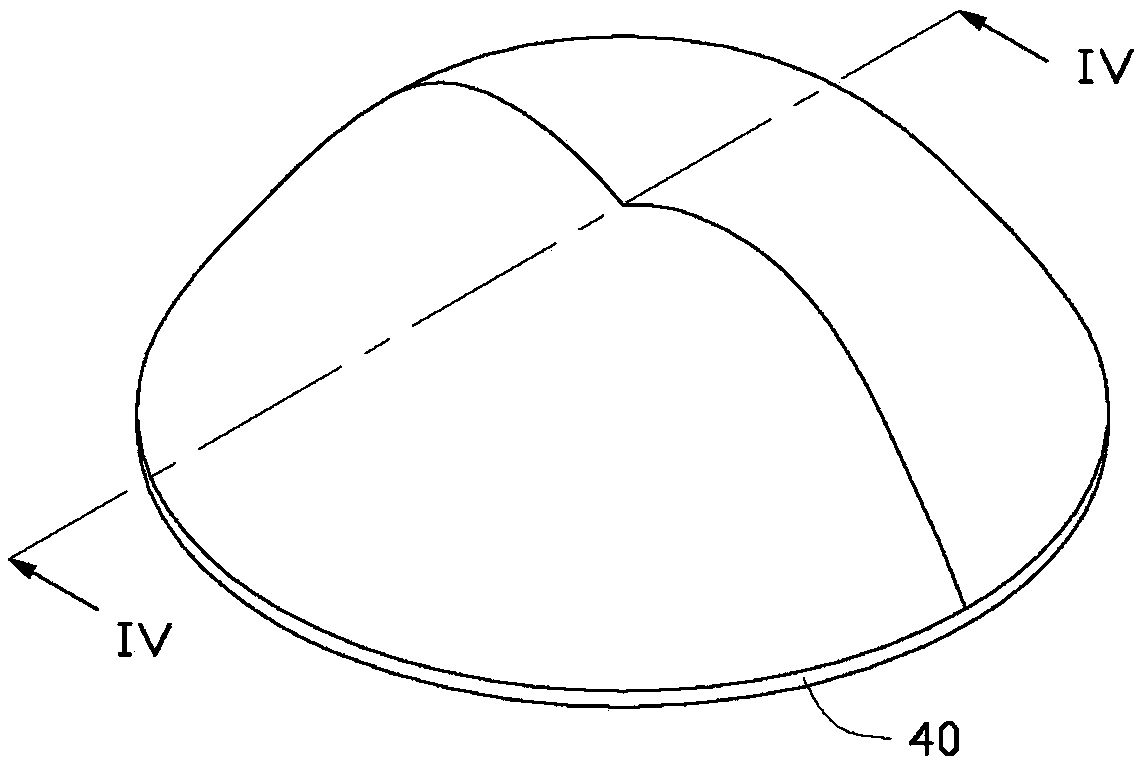

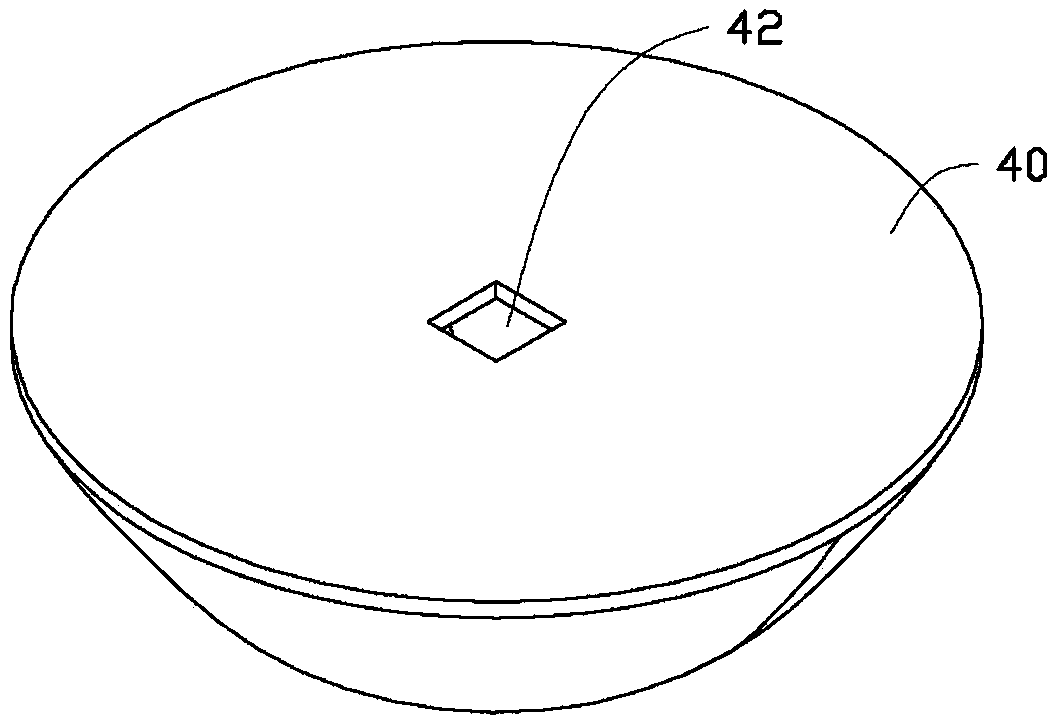

[0019] Please also see Figure 2 to Figure 4 , the lens 30 includes a base 40 , a first diverging portion 50 disposed on the base 40 , and a second diverging portion 60 disposed on the base 40 and accommodating the first diverging portion 50 inside.

[0...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap