Coking coal blending method with fluidity ≥ 1000ddpm gas coal

A technology of 1000ddpm, coking coal, applied in the field of coal chemical industry, can solve the problems of high actual value, the fluidity of blended coal should not be too high, and should not be too low, so as to reduce the cost of coal blending and save high-quality fat coal resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

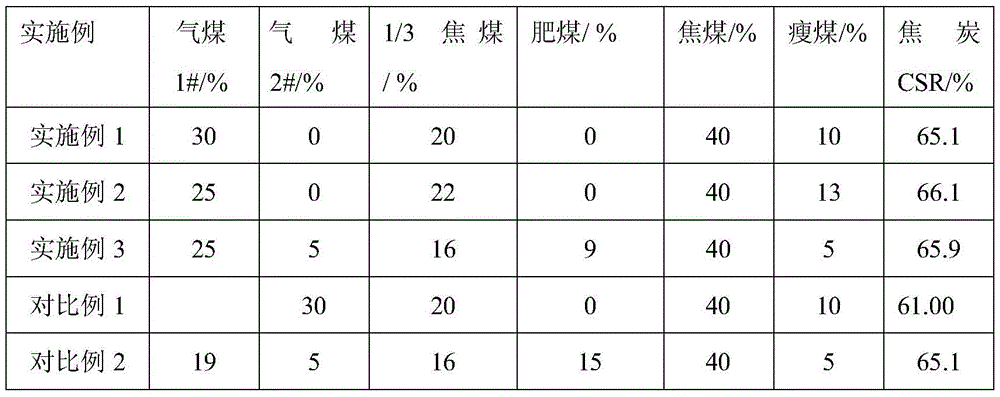

Embodiment 1

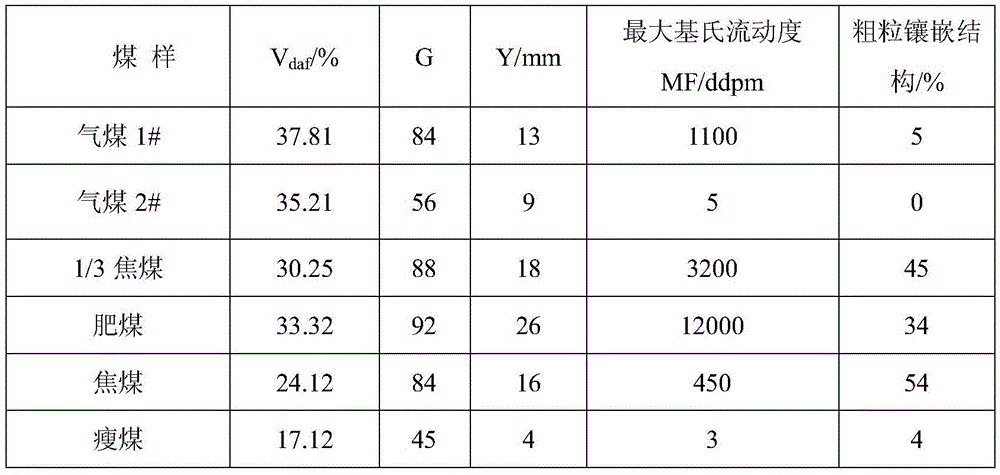

[0017] The cokes obtained in Examples 1-3 and Comparative Examples 1-2 were all produced in coke ovens over 6 meters long without using coal humidity control, briquette technology and pre-crushing technology. Comparative example 1 is compared with embodiment 1, and embodiment 1 gas coal is all gas coal 1#, and in comparative example 1 gas coal is all gas coal 2#, because gas coal 2# has no fluidity, after large-scale addition, The post-reaction thermal strength (CSR) of the coke obtained was 61%, which was significantly different from the thermal performance of Example 1, and the coke strength could not meet the requirements for use. Compared with Example 3 in Comparative Example 2, after replacing 6% fat coal with gas coal 1# in Example 3, the post-reaction thermal strength (CSR) of the coke obtained is equivalent to Comparative Example 2, and it can be seen that Gas Coal 1# has With a certain fluidity, it can partially replace fat coal in the coal blending structure to achie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volatile matter | aaaaa | aaaaa |

| volatile matter | aaaaa | aaaaa |

| volatile matter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com