Heat dissipation structure for air convection heat dissipation LED lamps

A technology of LED lamps and air convection, applied in lighting and heating equipment, cooling/heating devices of lighting devices, lighting devices, etc., can solve the problems of low heat dissipation efficiency, high heat dissipation cost, and many heat dissipation parts, and achieve reduction Heat dissipation cost, improvement of heat dissipation effect, and effect of increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

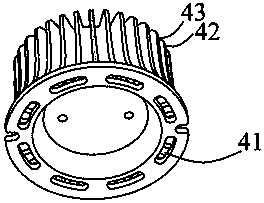

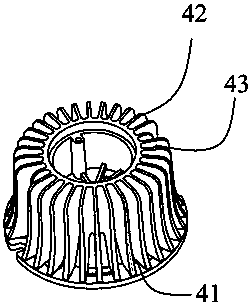

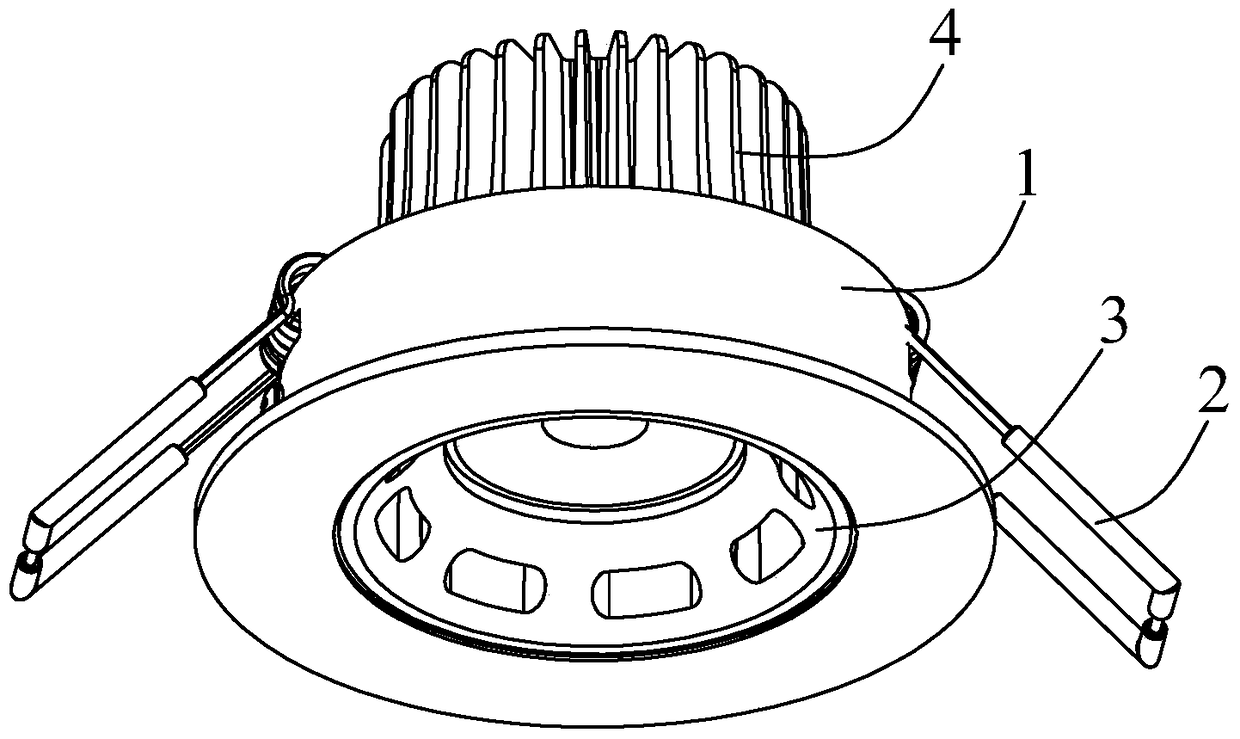

[0018] Please refer to Figure 1 to Figure 6 As shown, a heat dissipation structure for air convection heat dissipation LED lamps is described below in conjunction with an embodiment, including an outer ring 1, a spring 2, a fixing ring 3, a heat sink 4, an optical device 5, an LED COB optical lens 6, and a wire buckle for fixing Sheet 7 and anti-pull fixed line buckle 8.

[0019] Please refer to Figure 5 and Figure 6 As shown, the fixed ring 3 is composed of a hollow cylinder, the two sides of the outer periphery of the cylinder are respectively provided with outwardly protruding fixed columns 31, and the inside of the fixed ring 3 is respectively provided with an inner ring integrated with the side wall of the cylinder. body 32, an outer ring body 33 corresponding to the inner ring body 32, an annular gap layer 34 is formed between the inner ring body 32 and the outer ring body 33, and a plurality of Inner ring heat dissipation holes 35 , the inner ring heat dissipation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com