Method for machining impeller end face teeth and gear shaft end face teeth matched with impeller end face teeth

An end face tooth and gear shaft technology, which is applied in the field of CNC machining of centrifugal air compressor products, can solve the problems affecting the popularization and application of wedge face end teeth, poor tooth surface contact, poor contact surface, etc. The effect of minimizing the degree error and improving the correction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Preferred embodiments of the present invention will now be described with reference to the accompanying drawings.

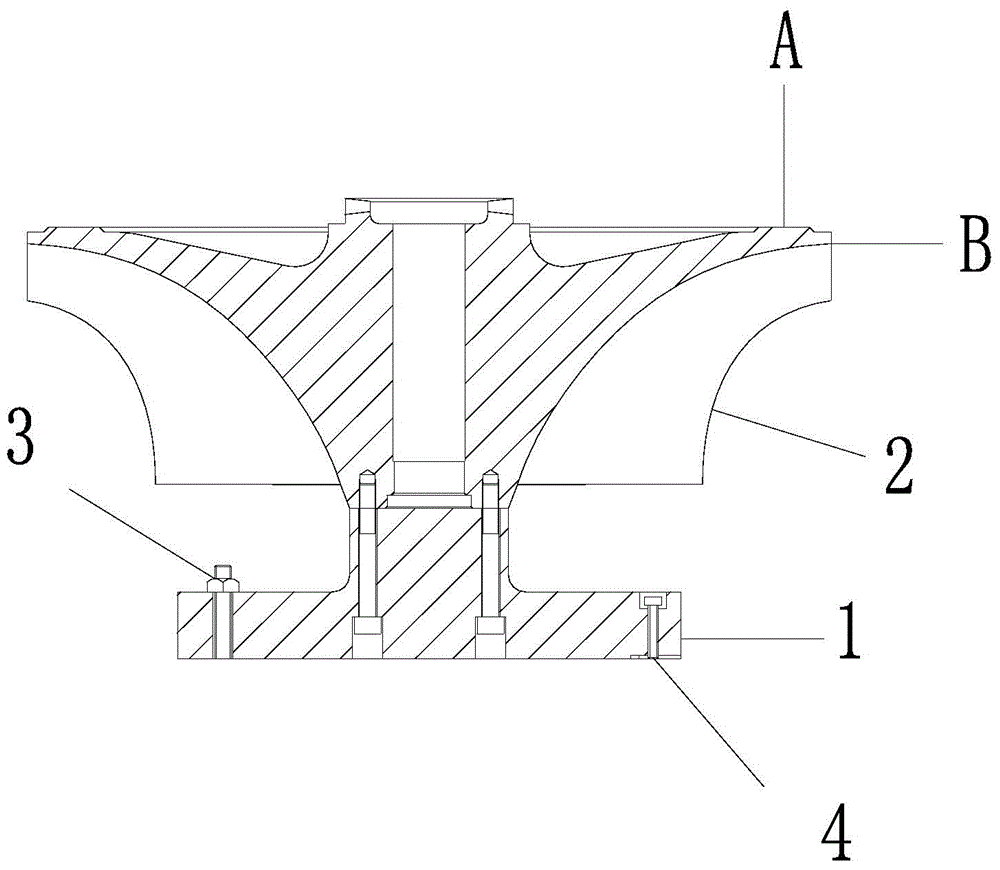

[0022] figure 1 Is the schematic diagram of impeller processing and installation. In the figure, A refers to the outer end face of the rear disc of the impeller 2, and B refers to the outer circle of the impeller rear disc, and the outer circle and the outer end face are calibration benchmarks in each process of impeller processing. The impeller tooling 1 plays the role of connecting the machine tool, fixing the impeller 2, and adjusting the levelness of the end surface. The impeller tooling 1 is locked on the machine tool with the locking mechanism 3, and the adjusting mechanism 4 adjusts the position of the impeller 2 on the machine tool by adjusting the impeller tooling 1.

[0023] Before processing, the impeller 2 and the impeller tooling 1 are assembled. After being hoisted to the CNC boring and milling machine workbench, the impeller is corrected b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com