Impeller cover structure of waterjet propulsion device and manufacturing method thereof

A water jet propulsion and impeller cover technology, which is applied in ship propulsion, propulsion components, ship construction, etc., can solve the problems of difficult repair and short service life of the impeller cover, and achieve the effects of avoiding direct contact, prolonging service life and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0052] Example 1:

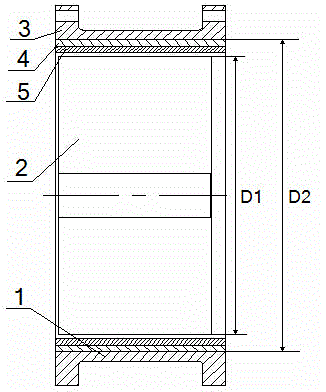

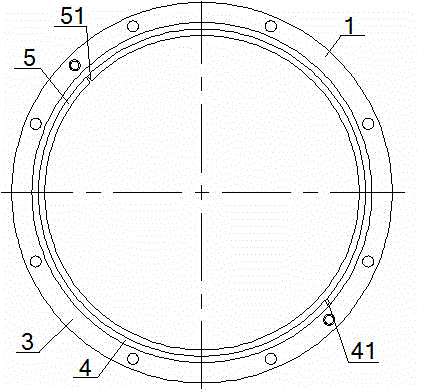

[0053] An impeller cover structure of a water jet propulsion device, comprising an impeller cover 1, an impeller 2, an impeller 2 is coaxially arranged in the middle of the impeller cover 1, and the impeller cover 1 includes a casing 3, an insulating bushing 4 and a stainless steel bushing 5. The outer circumferential surface of the stainless steel bushing 5 is press-fitted with the inner circumferential surface of the housing 3 through the insulating bushing 4, the middle of the stainless steel bushing 5 is provided with an impeller 2 coaxially, and the impeller 2 is in contact with the stainless steel The gap between the bushes 5 is 0.5 mm-1 mm; the shell 3 is a cast aluminum part with a tubular structure; the insulating bush 4 is made of high-density polyethylene board, polytetrafluoroethylene board or polymer The thickness of the insulating bushing 4 is 2 mm-3 mm; the stainless steel bushing 5 is rolled from the stainless steel plate, and the thickness of ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap