Low thermal shrinkage rate culture stone mold glue and preparation method thereof

A technology of shrinkage rate and cultural stone, applied in the field of silicone rubber materials, can solve the problems of not being able to clearly show the original style of stone, affecting the fineness of cultural stone decoration, appearance, and apparent color, etc., to achieve a good low shrinkage rate , Not easy to deform, stable composition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0028] Example 1

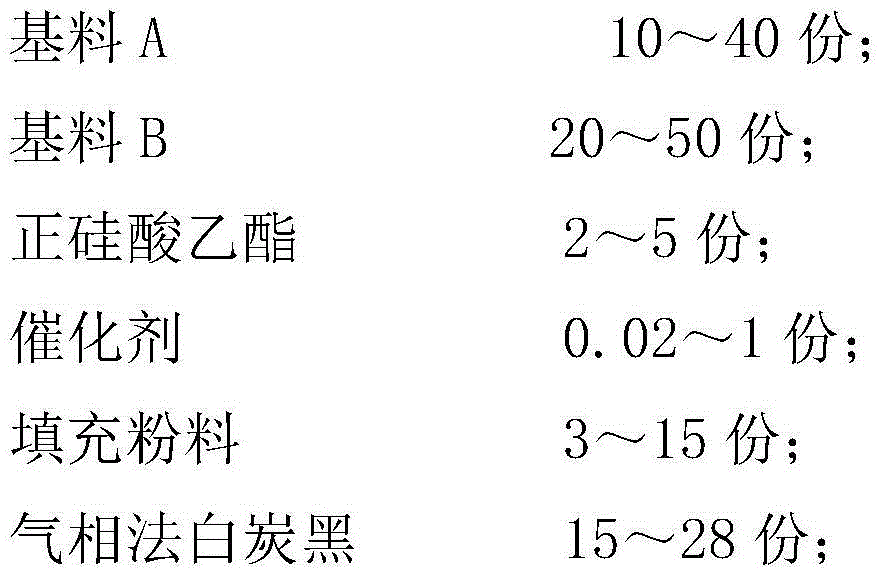

[0029] A low heat shrinkage cultural stone mold glue, its raw material formula is composed of the following components by weight:

[0030]

[0031] The base material A is 107 room temperature vulcanized silicone rubber with a viscosity of 700mpa.s;

[0032] The base material B is 107 room temperature vulcanized silicone rubber with a viscosity of 50000mpa.s;

[0033] The catalyst is dibutyl tin dilaurate;

[0034] The filling powder is silicon micro powder.

[0035] The preparation method of the above-mentioned low heat shrinkage cultural stone mold glue is:

[0036] According to the components and parts by weight of the above formula, mix base material A, base material B, ethyl orthosilicate, catalyst, filler powder and fumed silica at 1500 rpm for 30 minutes until uniform , Then vacuum degassing under a vacuum of -0.095MPa; then pour it into a mold and perform a curing reaction at 25° C. for 60 minutes to obtain the low heat shrinkage cultured stone mold glue.

Example Embodiment

[0037] Example 2

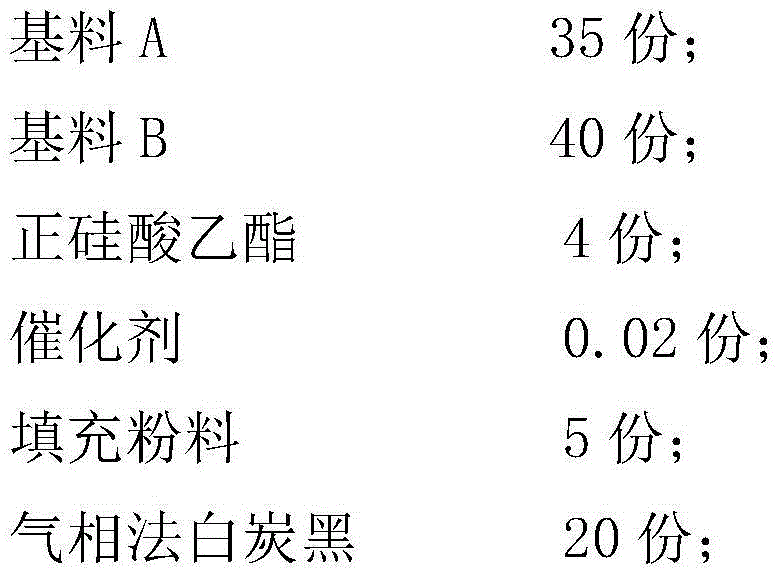

[0038] A low heat shrinkage cultural stone mold glue, its raw material formula is composed of the following components by weight:

[0039]

[0040]

[0041] The base material A is type 107 room temperature vulcanized silicone rubber with a viscosity of 600mpa.s;

[0042] The base material B is 107 room temperature vulcanized silicone rubber with a viscosity of 55000mpa.s;

[0043] The catalyst is stannous octoate;

[0044] The filling powder is silicon micro powder.

[0045] The preparation method of the above-mentioned low heat shrinkage cultural stone mold glue is:

[0046] According to the components and parts by weight of the above formula, mix base material A, base material B, ethyl orthosilicate, catalyst, filler powder and fumed silica at 2000 rpm for 50 minutes until uniform , Then vacuum degassing under a vacuum of -0.095MPa; then pour it into a mold and perform a curing reaction at 30°C for 40 minutes to obtain the low heat shrinkage cultured stone mold glue....

Example Embodiment

[0047] Example 3

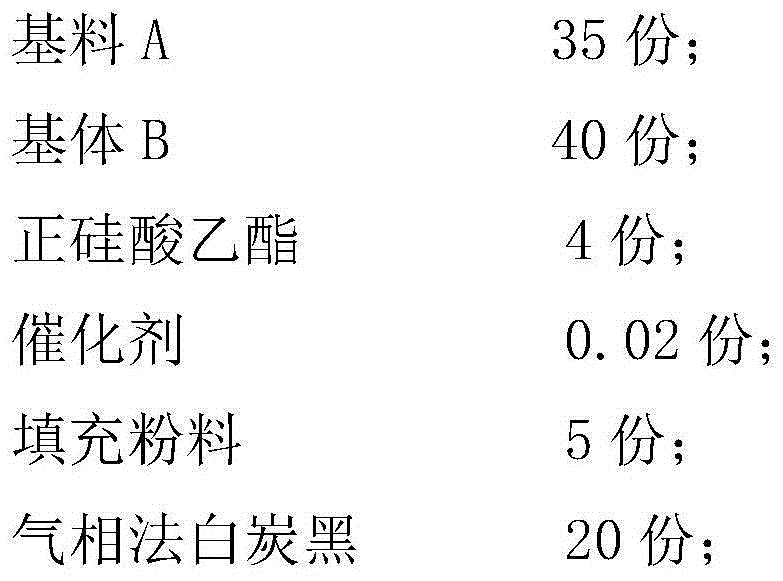

[0048] A low heat shrinkage cultural stone mold glue, its raw material formula is composed of the following components by weight:

[0049]

[0050] The base material A is type 107 room temperature vulcanized silicone rubber with a viscosity of 800mpa.s;

[0051] The base material B is type 107 room temperature vulcanized silicone rubber with a viscosity of 45000mpa.s;

[0052] The catalyst is dibutyltin bis(dodecylsulfide);

[0053] The filling powder is silicon micro powder.

[0054] The preparation method of the above-mentioned low heat shrinkage cultural stone mold glue is:

[0055] According to the components and parts by weight of the above formula, mix base material A, base material B, ethyl orthosilicate, catalyst, filler powder and fumed silica at 3000 rpm for 60 minutes until uniform , Then vacuum degassing under a vacuum of -0.095MPa; then pour it into a mold and perform a curing reaction at 30°C for 20 minutes to obtain the low heat shrinkage cultured stone ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap