A Radiation Oriented Ring Forming Equipment

A technology of radiation orientation and forming equipment, which is applied in the field of hydraulic presses, can solve the problems of increasing the space volume of the device, low magnetic performance of the product, and low magnetic field strength, and achieve the effects of enhanced magnetic field strength, uniform radial arrangement of magnetic domains, and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

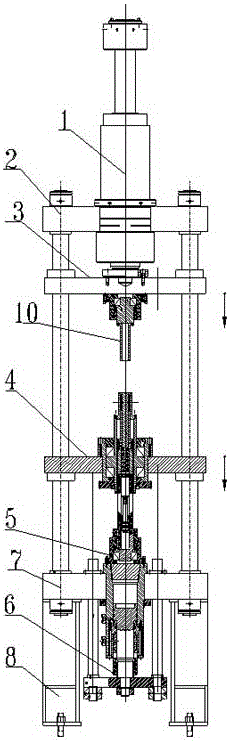

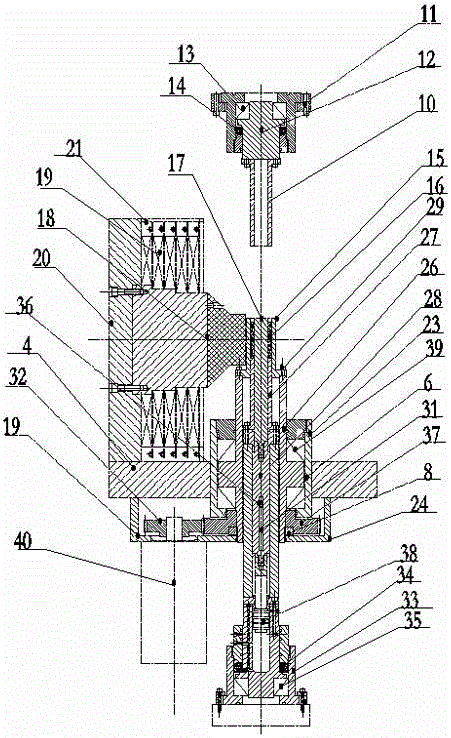

[0031] Such as figure 1 with figure 2 As shown, a radiation orientation ring forming equipment of the present invention includes a main cylinder 1, an upper beam 2, an upper slider 3, a female template 4, a central cylinder 5, a top cylinder 6, a workbench 7 and a support 8,

[0032] The above-mentioned upper beam 2, upper slider 3, female formwork 4, workbench 7 and support 8 are arranged sequentially from top to bottom. The four corners of the female template 4 are slidably matched with the guide post 9, and the bottom of the workbench 7 is supported by the support 8;

[0033] On the upper slider 3, an upper punch 10, an upper punch rotating assembly and an upper punch mounting seat 11 are installed, and the upper punch mounting seat 11 is fixed at the middle position of the upper sliding block 3, and the upper punch rotating assembly is composed of an upper punch connecting body 12, a bearing assembly A and bearing group mounting seat A, bearing group A thrust self-align...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com