Table tennis bat bottom plate side polishing machine

A table tennis racket and bottom plate technology, which is applied in the direction of grinding/polishing equipment, grinding/polishing safety devices, machine tools suitable for grinding workpiece planes, etc., which can solve the problem of skin abrasion of users, low production efficiency and affecting users Hand feeling and other problems to achieve the effect of improving uniformity and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

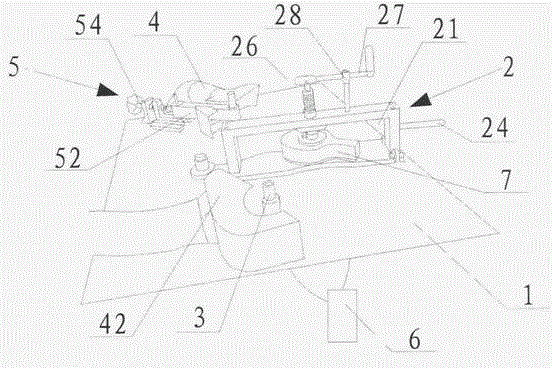

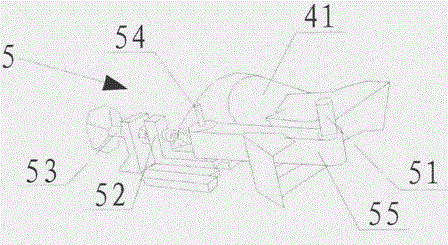

[0024] like figure 1 The table tennis racket base plate edge light machine shown mainly includes a desktop 1, a fixed assembly 2, a grinding wheel rod 3, a fine grinding assembly 5 and an electric control assembly 6.

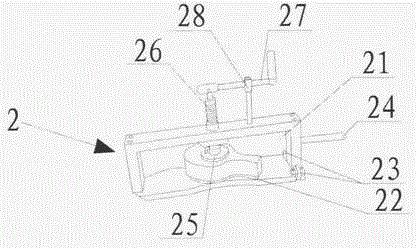

[0025] Wherein, the desktop 1 is parallel to the ground, and is supported on the ground for supporting other parts of the table tennis racket bottom plate side light machine. The fixing assembly 2 is arranged on the desktop 1, and it mainly includes a frame body 21, a template 22, a pressing plate 25 and bolts 26; the frame body 21 stands vertically on the desktop 1, and one end thereof is pivotally connected with the desktop 1, so that the frame body 21 can rotate on the desktop 1 around the pivot; the shape of the template 22 is consistent with the shape of the table tennis bottom plate, and it is installed in the frame bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com