PTFE pushing machine

A technology of PTFE and pusher, which is applied in the field of PTFE pusher, can solve the problems of unstable extrusion, fast and slow running speed, etc., and achieve the effect of large output torque and high working precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

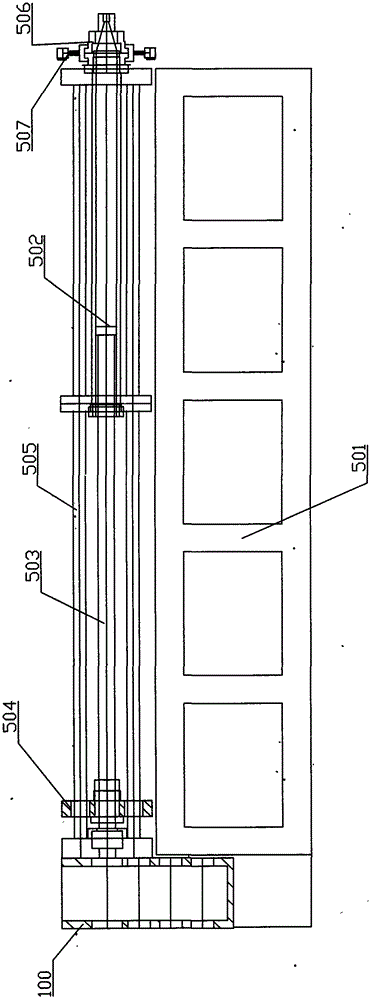

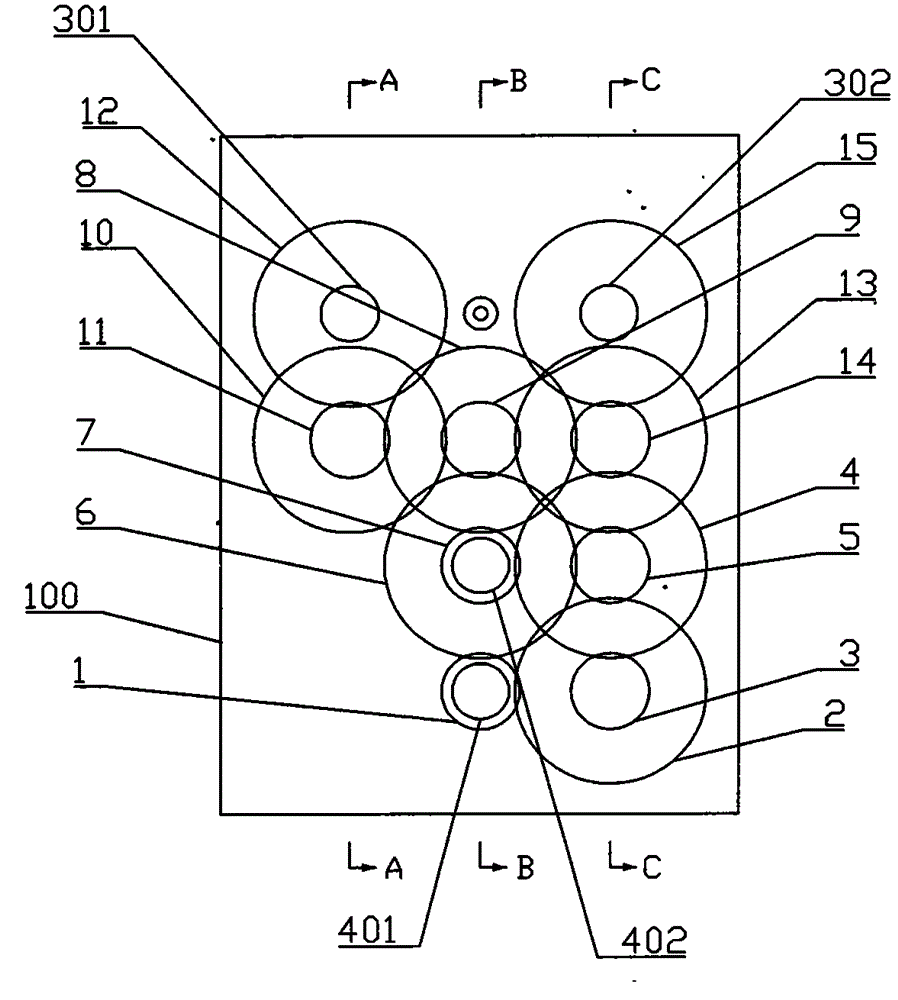

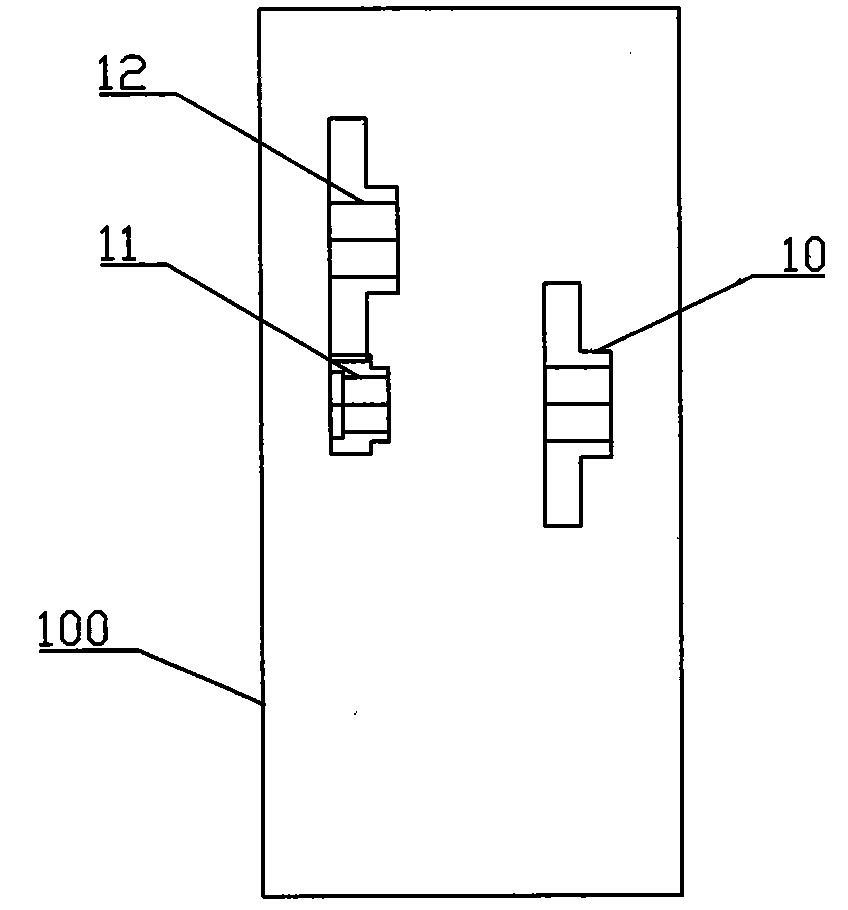

[0025] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see Figure 1-Figure 4 ;

[0026] The PTFE pushing machine given in this embodiment includes a main body of a horizontal pushing machine and a double-input reducer. Plate 504, polished rod 505, mold 506 and hydraulic clamping device 507, the cylinder is installed on the machine base 501, the piston 502 is arranged in the cylinder and forms a sealing fit with the cylinder, and the mold 506 is sealed by the hydraulic clamping device 507. Assembled on the front end of the cylinder; the screw rod 503 is rotatably connected with respect to the machine base 501, and the nut on the moving push plate 504 matches the screw rod, and the nut and the screw rod form a screw nut pair, through the rotation of the screw rod Make the moving push plate move axially along the screw rod. The moving push plate 504 forms a sliding connection with the polished rod 505 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com