Safety device at joint between water inlet pipe base and water inlet pipe flange in boiler drum

A boiler steam drum and safety device technology, applied in the field of facilities and safety devices, can solve problems such as difficulty in maintenance, uneven heating of pipes, corrosion, etc., and achieve the effects of reducing technology input costs, scientific and reasonable structural design, and unique measures

Inactive Publication Date: 2014-11-19

广西田东南华糖业有限责任公司一糖厂

View PDF5 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] During the operation of the equipment, after the asbestos gasket in the middle of the connecting flange has been used for a period of time, due to the aging of the asbestos gasket between the flanges, the quality of the asbestos board or the level of installation technology, the temperature and water intake of the boiler Corrosion of water in the pot and other problems will cause damage to the asbestos gasket

Therefore, the asbestos gasket is damaged and cracked due to aging and other problems, causing part of the furnace water in the pipe to be sprayed directly from the damaged gap, and the steam-water separator installed inside the boiler drum is on the upper part of the flange, and the water that is sprayed into the furnace Water is brought into the boiler superheater tube by the high-temperature and high-pressure steam flowing into the boiler superheater from the top of the steam drum. This is what people call "steam carrying water". , the tubes are heated unevenly, local overheating causes a tube burst accident, and the furnace is forced to shut down for treatment

At the same time, due to the aging of asbestos gaskets between flanges, quality problems or installation technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to view more

Login to view more PUM

Login to view more

Login to view more Abstract

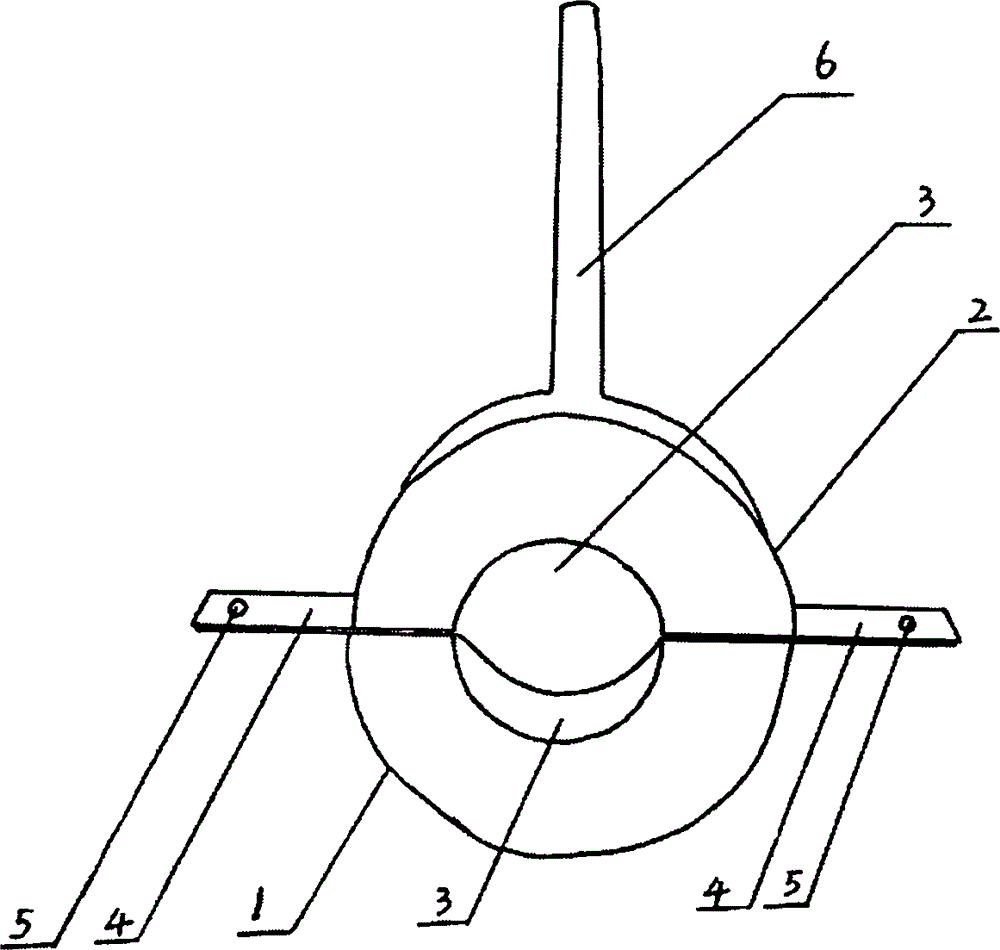

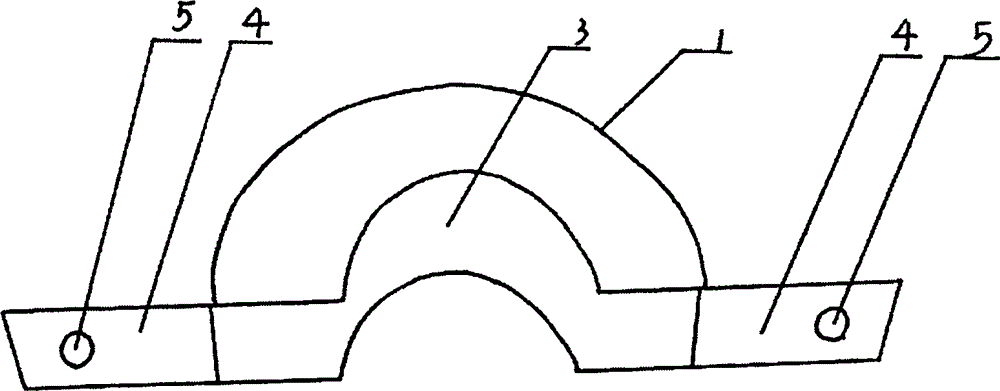

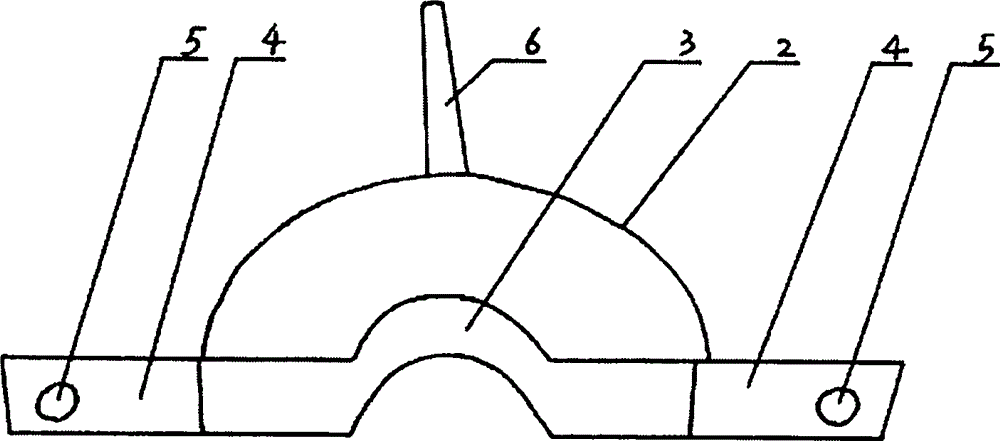

A safety device at the joint between a water inlet pipe base and a water inlet pipe flange in a boiler drum is composed of an upper cover and a lower cover, wherein the upper cover is of a semicircular structure and is hollow; the middle portion of the upper cover is further provided with a semicircular pipe passage hole; the left side and the right side of the upper cover are respectively provided with a connecting lug, and each connecting lug is provided with a screw hole; the structure and specifications of the lower cover are the same as those of the upper cover, and a drainage pipe is arranged at the bottom of the side wall of the lower cover. The joint between the water inlet pipe base and the water inlet pipe flange is protected by the safety device in the boiler drum. Once a gasket of the water inlet pipe flange breaks down and leaks water, the device redirects and collects the leaked water immediately so that sprayed water can return to the position below the normal water level of a boiler through the drainage pipe arranged on the lower cover of the device and can not be carried into a superheater pipe, that is, a safety device is provided for a boiler superheater, and consequently the accidents that the superheater carries water and the pipes are blasted are avoided.

Description

technical field [0001] The invention belongs to facilities and equipment in the field of sugar production, and in particular relates to a safety device at the junction of a water inlet pipe socket and a water inlet pipe flange in a boiler steam drum. technical background [0002] In the boiler equipment in the sugar field, when installing the boiler steam internal device, the traditional boiler steam drum internal water supply pipe, in order to facilitate disassembly, when installing the boiler steam drum internal water inlet pipe is usually a short pipe with an elbow and Originally welded on the wall of the steam drum to connect the short pipes, in which the water inlet elbow is connected with the pipe seat of the water inlet pipe previously welded on the wall of the boiler drum with a flange, and an asbestos gasket is added between the flanges to make the external boiler feed water pass through this section After the pipe, it continuously enters the overflow tank of the st...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more IPC IPC(8): F22B37/22

Inventor 阮廷仕

Owner 广西田东南华糖业有限责任公司一糖厂

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap