Safe shell type injector

A technology for a syringe and a safety shell, which is applied in the field of safety shell-type syringes, can solve the problems of reduced production efficiency, unfavorable packaging, bending of needle tubes, etc., and achieves the effects of reducing the number of parts and components, simplifying the assembly process, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

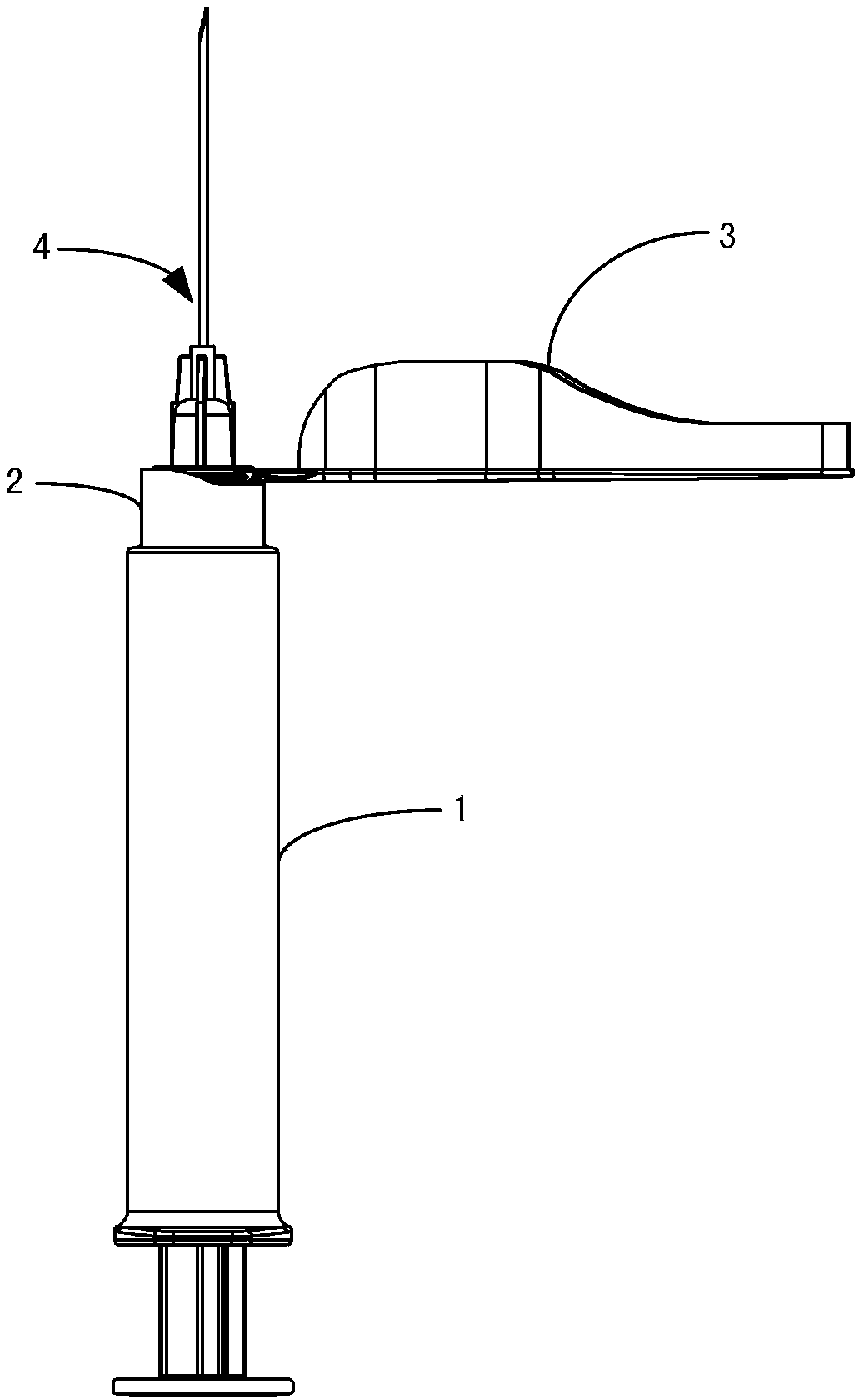

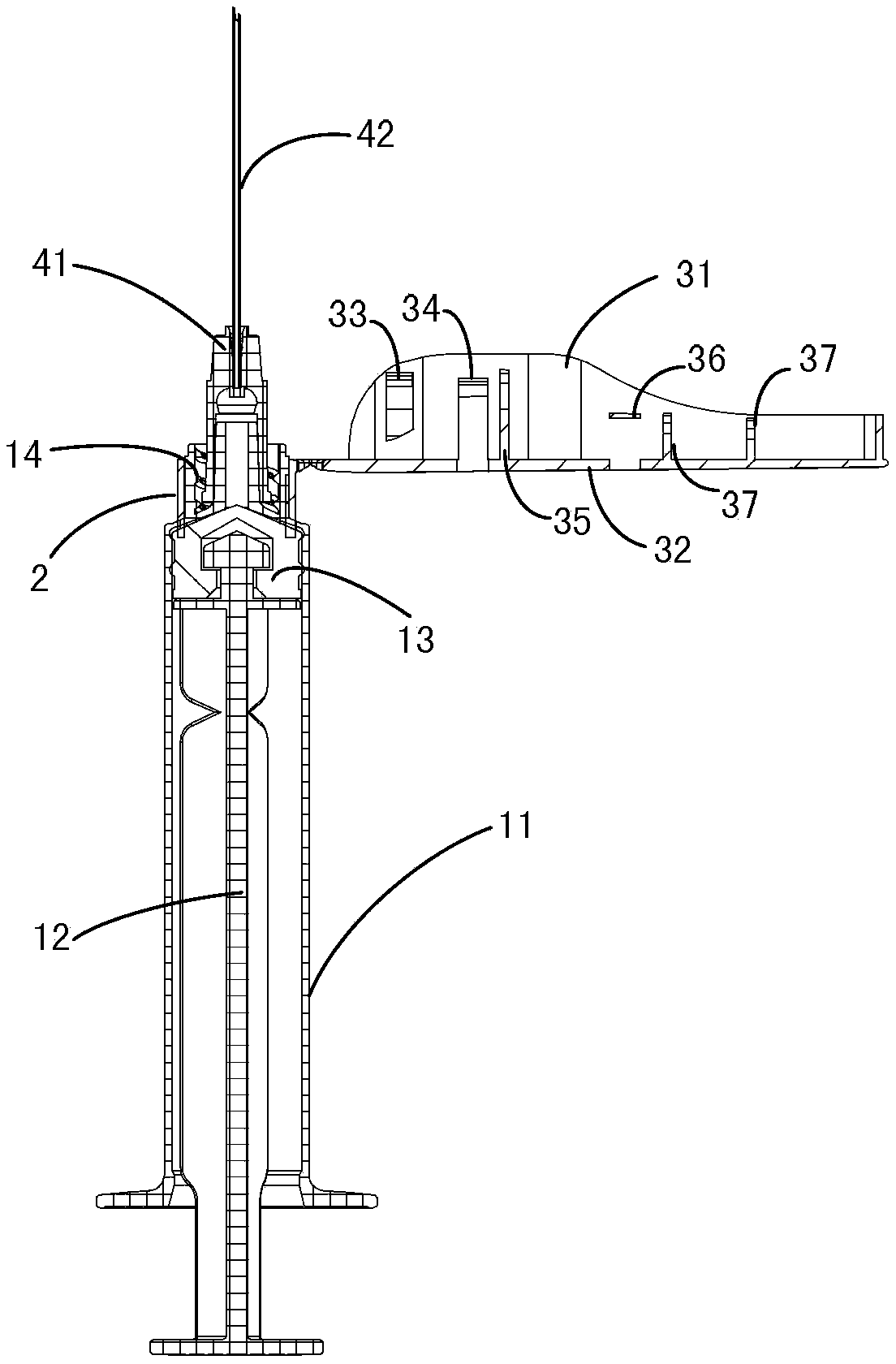

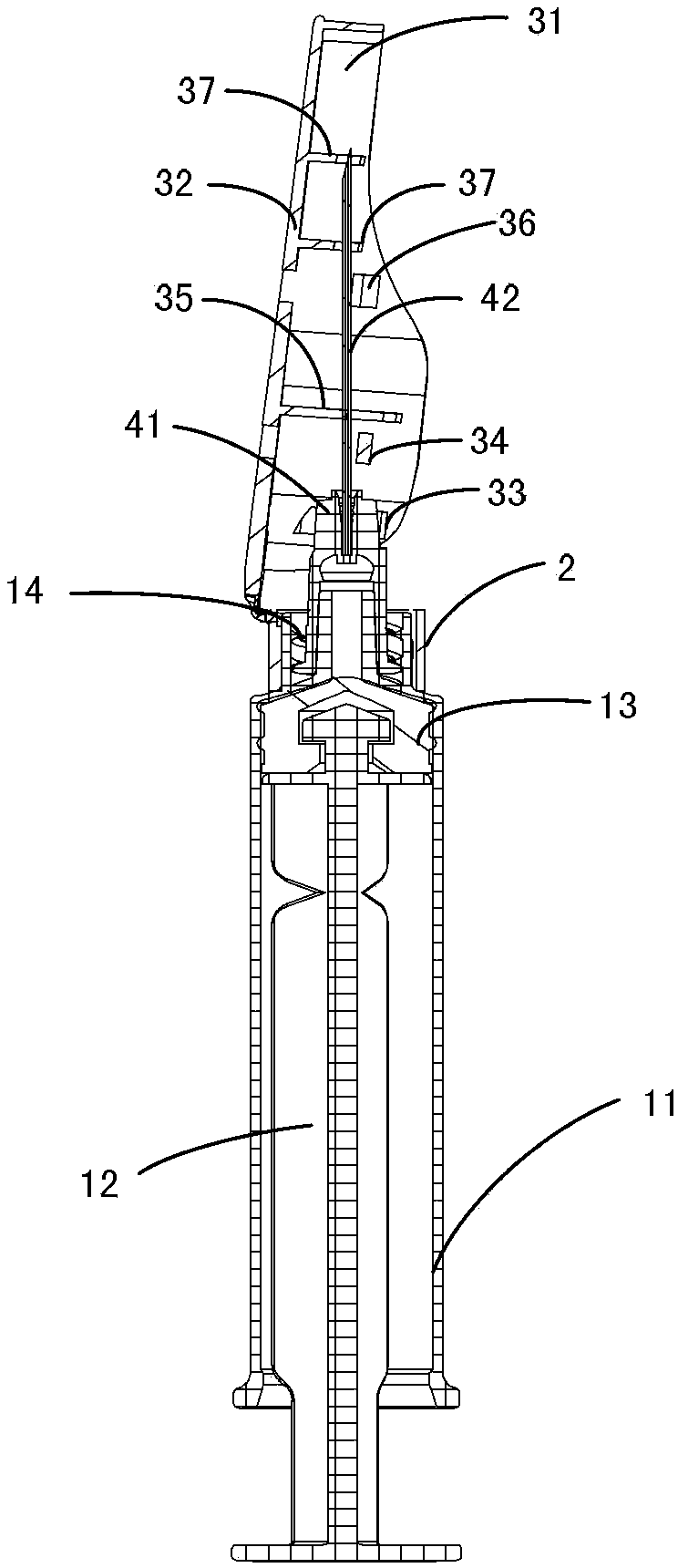

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

[0025] see Figure 1 to Figure 3 , the containment type syringe of the present invention includes a screw injector body 1 and a safety protection shell, the screw injector body 1 includes a syringe casing 11, a screw seat 14 located at the front end of the syringe casing 11, a core rod 12 located in the syringe casing 11, The rubber stopper 13 located at the front end of the core rod 12 and the syringe jacket 11, and the needle 4 installed on the screw seat 14, the needle 4 includes a needle tube seat 41 and a needle tube 42 fixed in the upper inner cavity of the needle tube seat 41, and the safety protection shell includes The collar 2 and the needle tube shield 3, the collar 2 is sheathed and fixed on the screw seat 14; the needle tube shield 3 is hinged on the collar 2, and the needle tube shield 3 has two side walls 31 and a The longitudinal opening formed by the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap