A filter material for decomposition of dioxin in high-temperature smoke and dust and its preparation method

A filter material and soot technology, which is applied in the field of filter material and its preparation for the decomposition of dioxin in high-temperature soot, can solve the problems of reducing fiber strength, fiber fragility, and low yield, so as to reduce loss and make the preparation process simple and easy line effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of filter material of the present invention comprises the following steps:

[0037] (1) Supported catalytic inner core: PTFE resin, activated carbon, and catalyst are evenly mixed in a weight percentage of 1:0.1~10:0.01~1, and then pressed and sintered at high temperature in sequence to obtain a supported catalytic inner core;

[0038] (2) Filter material for the decomposition of dioxins in high-temperature smoke and dust: the supporting catalytic inner core is filled in a film-coated dust removal bag and used as a support for the dust removal bag to obtain a filter material for the decomposition of dioxins in high-temperature smoke and dust.

[0039] The preferred pressing condition is normal temperature, the pressure is 0.02 MPa to 80 MPa, and the pressing time is 1 hour to 24 hours.

[0040] The preferred sintering conditions are a temperature of 200° C. to 360° C. and a sintering time of 1 hour to 24 hours.

[0041] Preferred catalysts can be...

Embodiment 1

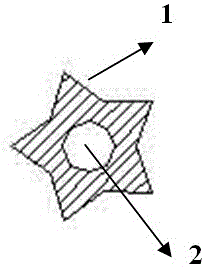

[0047] (1) Supporting catalytic inner core: Mix polytetrafluoroethylene resin, activated carbon, and catalyst in a weight percentage of 1:0.1:0.01, and follow the attached figure 1 The shape in is pressed at 0.02 MPa, pressed for 24 hours, and sintered at 200°C for 24 hours to prepare a supported catalytic inner core. The catalyst is a three-way catalyst of vanadium pentoxide-tungsten-titanium dioxide;

[0048] (2) Filtration material for dioxin decomposition in high-temperature smoke and dust: 8 supporting catalytic inner cores are packed in a film-coated dust removal bag to form a film-coated dust removal bag-supporting catalytic inner core structure to prepare dioxins in high-temperature smoke and dust The decomposed filter material has a particle interception efficiency of 99.95%, and a dioxin decomposition efficiency of 95%.

Embodiment 2

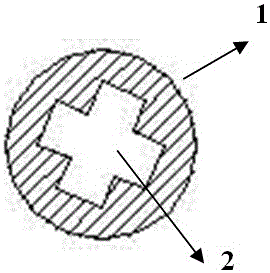

[0050] (1) Supporting catalytic inner core: mix polytetrafluoroethylene resin, activated carbon, and catalyst in a weight percentage of 1:10:1, and follow the attached figure 2 The shape is pressed at 80 MPa, pressed for 1 hour, and sintered at 360 ° C for 1 hour to prepare a supported catalytic inner core. The catalyst is a three-way catalyst of vanadium pentoxide-tungsten oxide-titanium dioxide;

[0051] (2) Filtration material for the decomposition of dioxins in high-temperature smoke and dust: 20 supporting catalytic inner cores are packed in a film-coated dust removal bag to form a film-coated dust removal bag-supporting catalytic inner core structure to prepare dioxins in high-temperature smoke and dust The decomposed filter material has a particle interception efficiency of 99.999%, and a dioxin decomposition efficiency of 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com