Double-faced carving machine for wooden door leaf

A technology of engraving machine and door leaf, applied in the direction of decorative art, processing models, etc., can solve the problems of low production efficiency and misalignment of door leaf patterns, etc., and achieve the effect of high production efficiency, improved production efficiency, and small labor load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0022] In the following, a double-sided engraving machine for wooden door leaf created by the present invention will be further described with reference to the accompanying drawings.

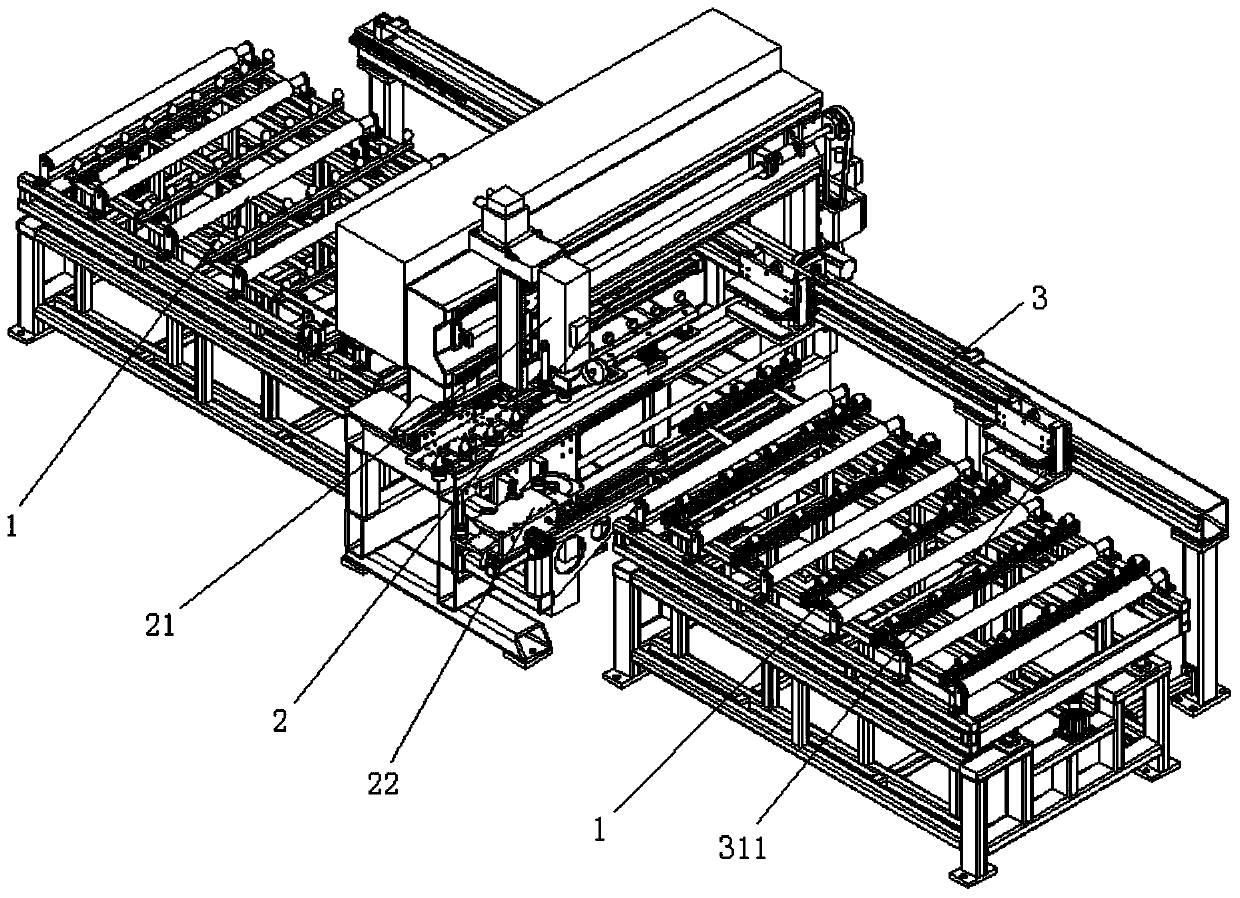

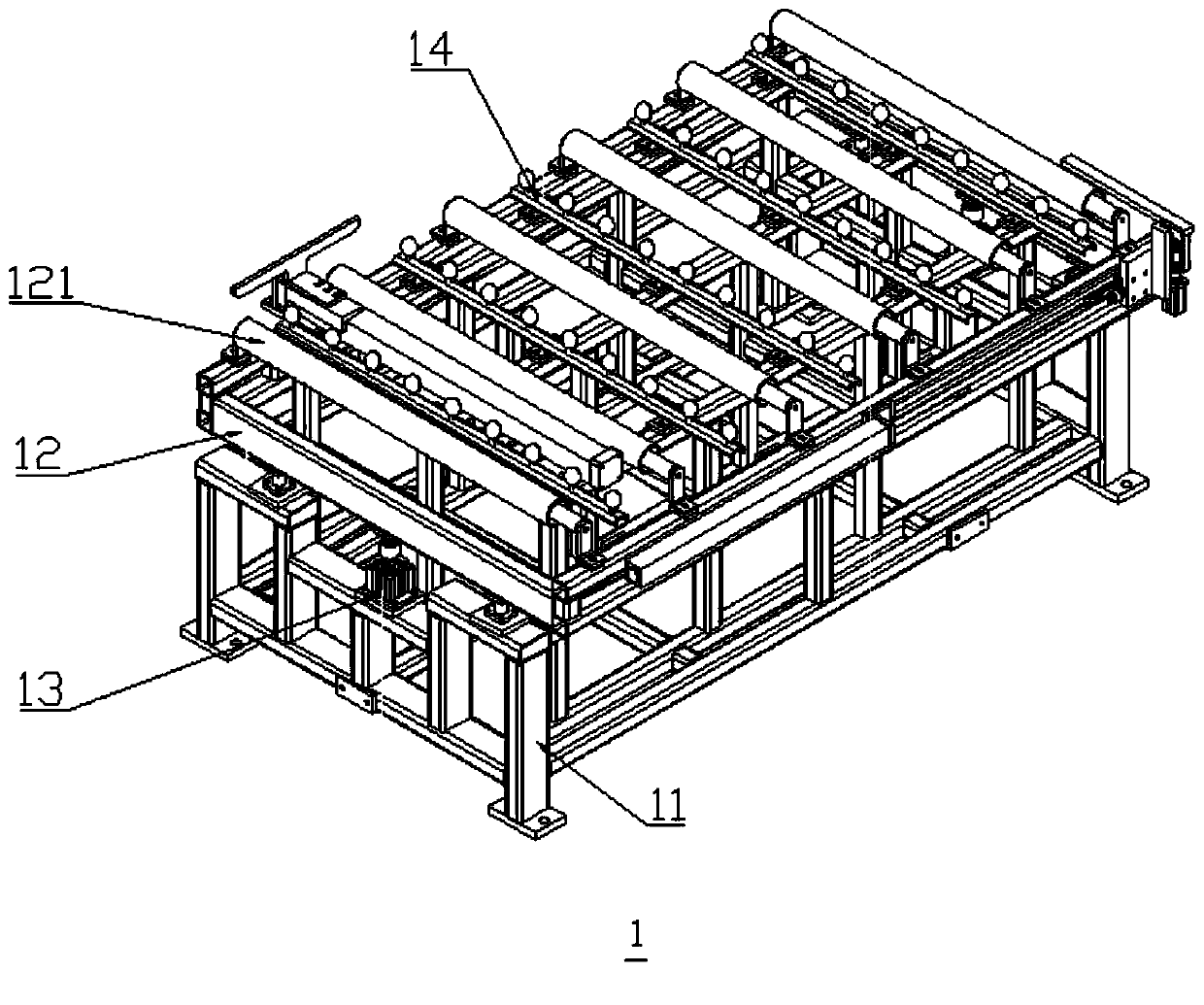

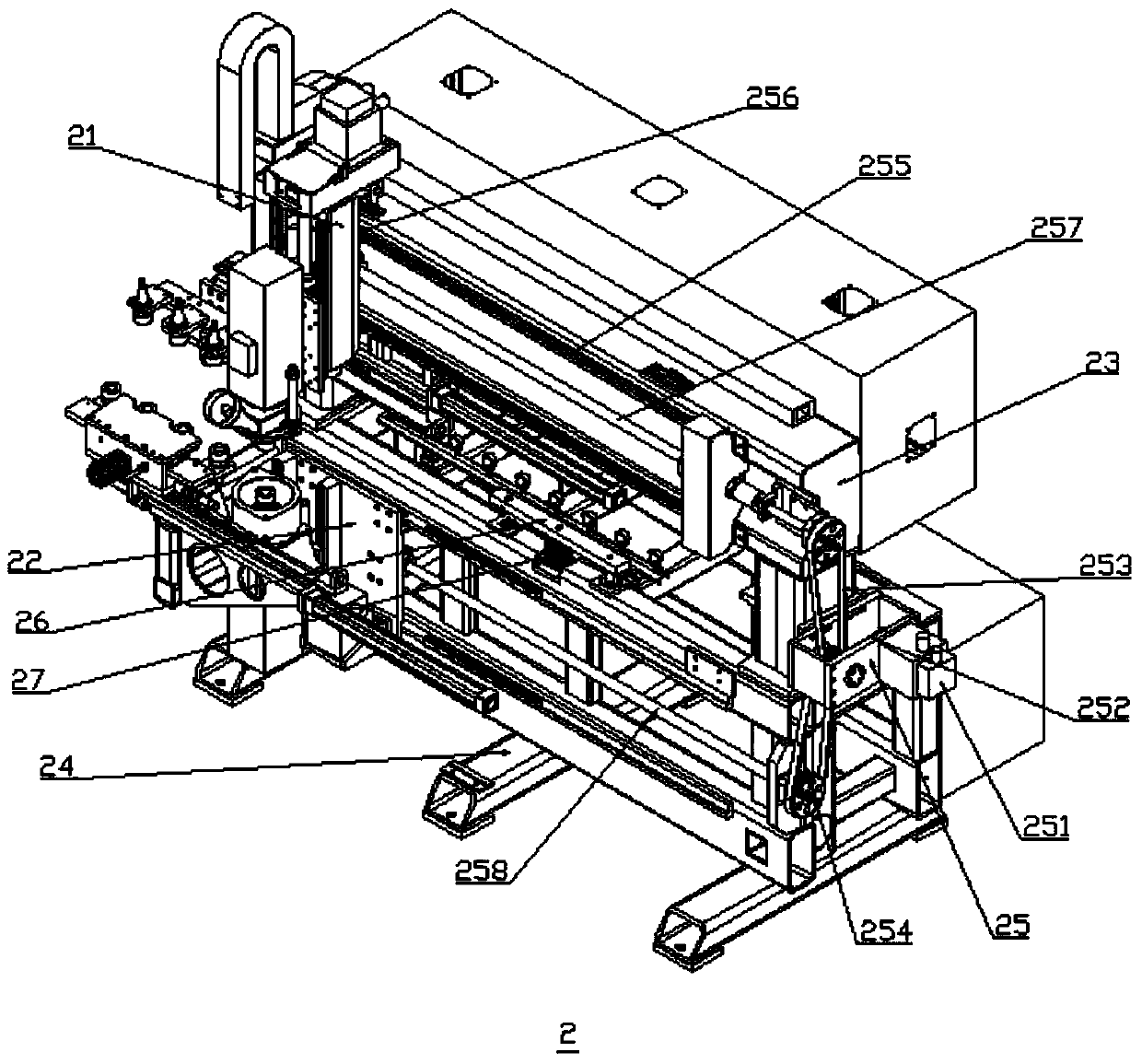

[0023] Such as figure 1 As shown, the wooden door leaf double-sided engraving machine includes a worktable 1, a double-sided engraving component 2 and a horizontal conveying device 3. The conveying direction of the door leaf is set to the X-axis direction of the engraving machine, which is the same horizontal plane as the X-axis and perpendicular to the X-axis. Is the Y-axis direction of the engraving machine, and the vertical direction is the Z-axis direction of the engraving machine. The double-sided engraving machine has a length reference 26 for determining the position of the door leaf in the X-axis direction; the horizontal conveying device 3 has a width reference 311 for determining The position of the door leaf in the Y-axis direction; the horizontal conveying device 3 is used to convey th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap