Automobile guy cable, automobile brake and automobile

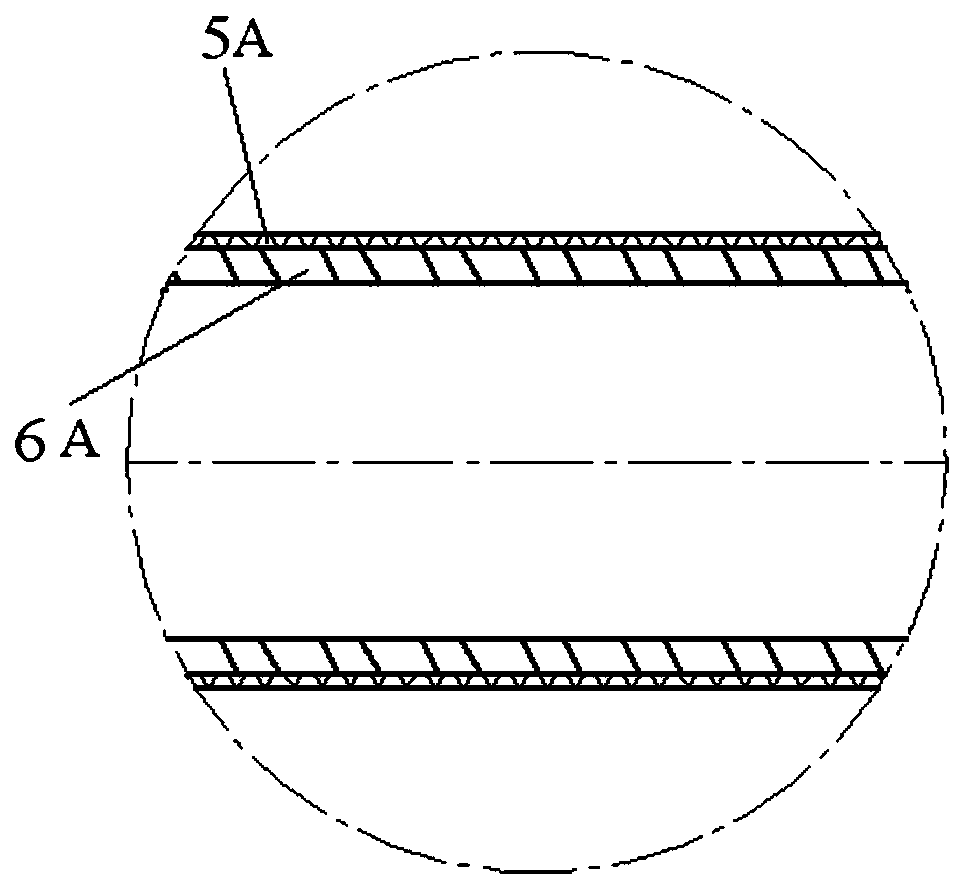

A technology of automobile braking and automobile, applied in the direction of brake actuators, linear motion shafts, gear transmission mechanisms, etc., can solve the problems of poor reliability, cracking of the outer sheath 5A, etc., and achieve the effect of reducing the cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

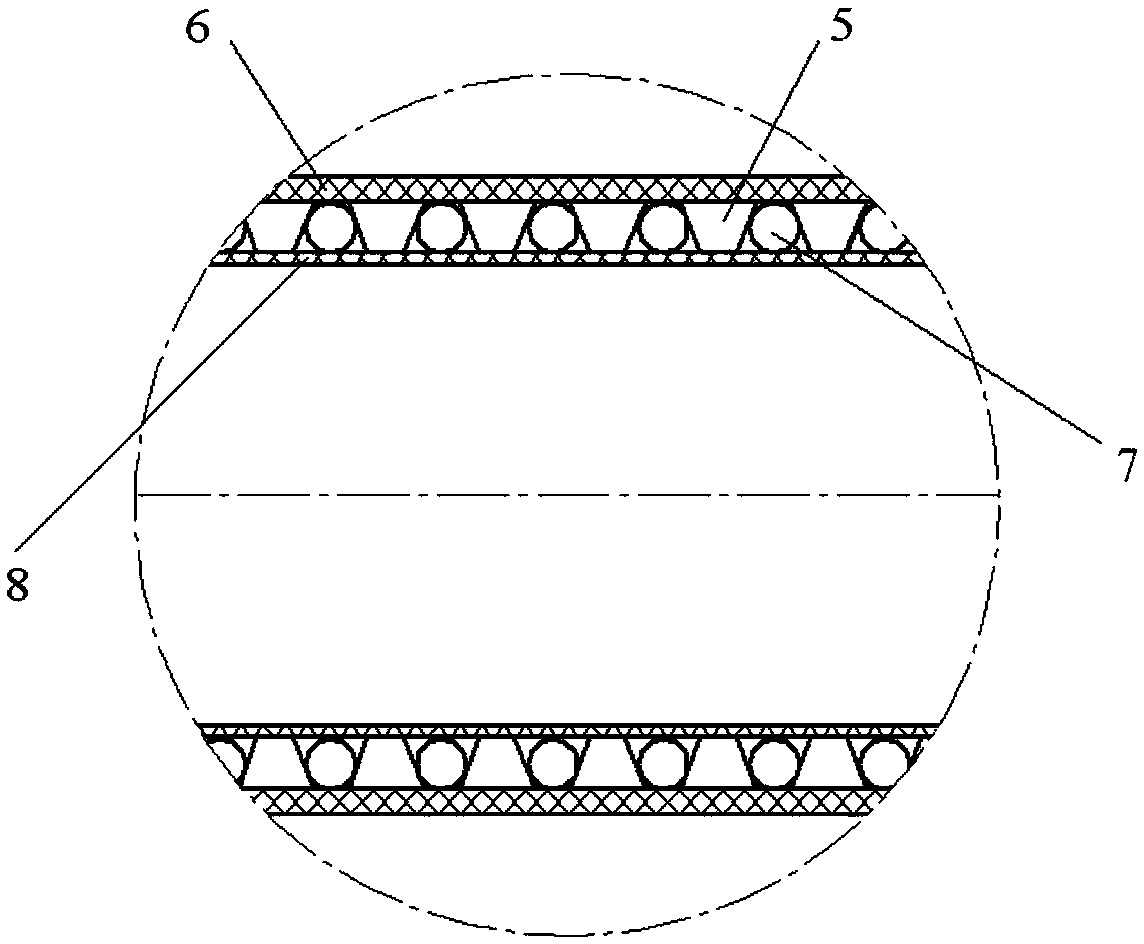

[0027] Such as image 3 As shown, a kind of automobile cable provided in this embodiment includes a spring assembly and an outer sheath 5 that is sleeved on the outer wall of the spring assembly. The spring assembly includes at least one round wire spring 7 and at least one flat wire spring 6. Each flat wire spring The coil of round steel wire spring 7 is sandwiched between the adjacent spring coils of 6.

[0028] Specifically, the round steel wire spring 7 refers to a spring wound with a round steel wire, the cross section of the round steel wire is circular or roughly circular (such as a multi-strand coil spring), and the flat steel wire spring 6 refers to a spring made of a flat steel wire. The spring that is wound, the cross section of flat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com