Microsphere-based miniature hemispherical resonant gyroscope and manufacturing method thereof

A technology of hemispherical resonant gyroscope and hemispherical resonator, which is applied in the process of producing decorative surface effect, microstructure technology, microstructure device, etc., which can solve the problem of affecting the miniature hemispherical resonator, the inability to accurately manufacture hemispherical molds, and the inability to realize Automatic alignment and other issues to achieve the effect of good symmetry and high smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

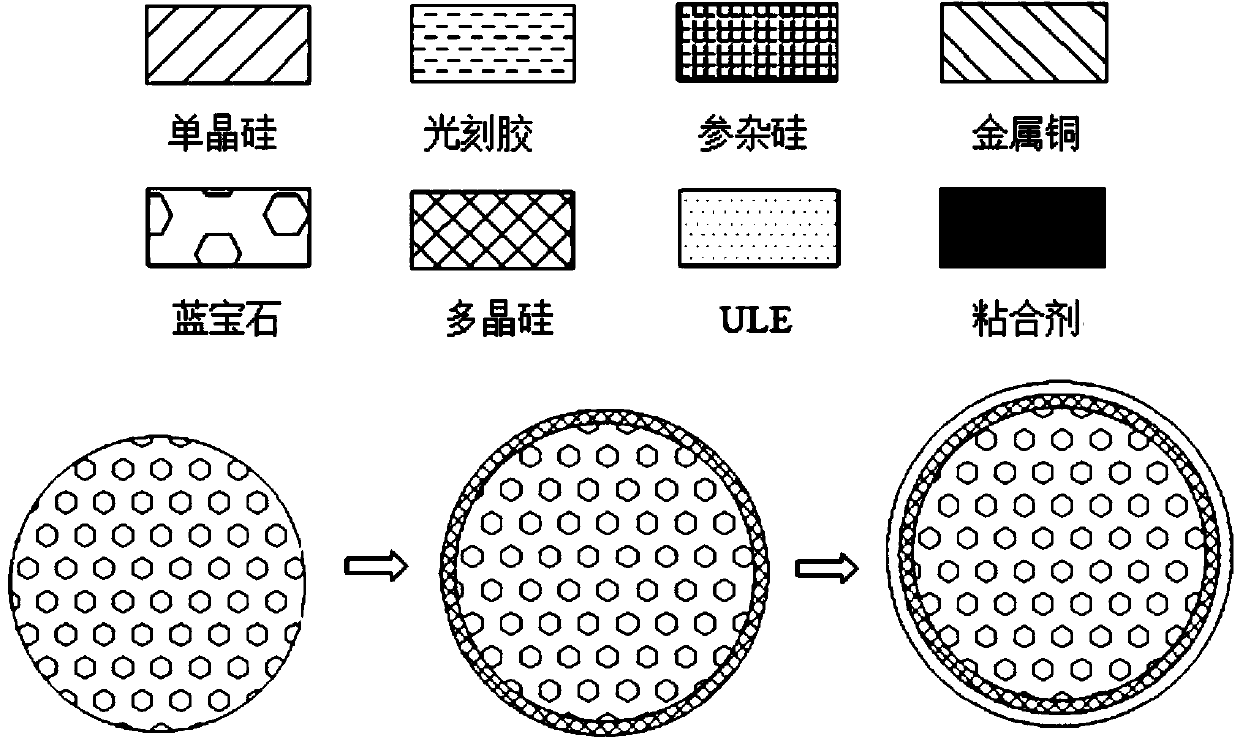

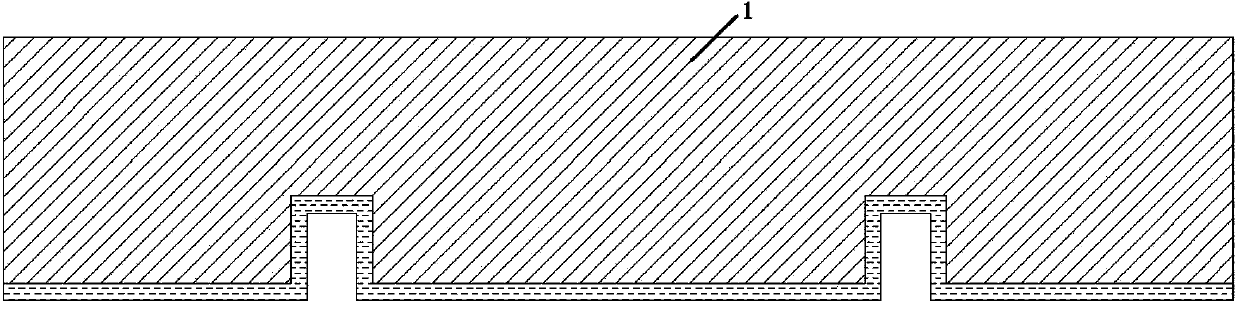

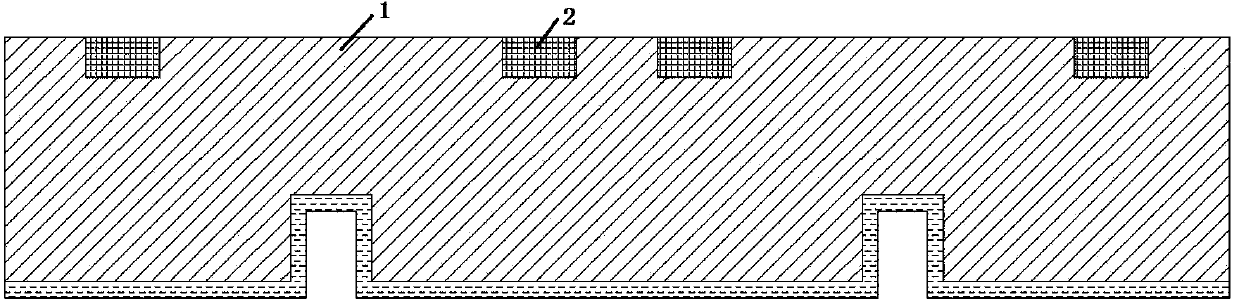

[0031] Such as figure 2 As shown, the present embodiment provides a micro-hemispherical resonant gyroscope based on microspheres, including:

[0032] a single crystal silicon substrate 1;

[0033] Eight evenly distributed electrodes 2;

[0034] A miniature hemispherical harmonic oscillator 3;

[0035] a back circular hole 4;

[0036] an adhesive layer 5;

[0037] Wherein: the central axis of the miniature hemispherical resonator 3 coincides with the central axis of the back circular hole 4 to achieve precise positioning and automatic alignment; the miniature hemispherical resonator 3 is fixed on the monocrystalline silicon substrate 1 through the adhesive layer 5; eight The electrodes 2 are evenly distributed around the micro-hemispheric resonator 3 .

[0038] In this embodiment, the gyroscope uses a microsphere with good structural symmetry and high smoothness to make a micro-hemispherical resonator 3; the gyroscope has a circular hole 4 on the back, which can realize m...

Embodiment 2

[0055] It is basically the same as Example 1, the difference is:

[0056] In the fourth step of the preparation method of the micro-spherical resonant gyroscope based on microspheres, the sputtered metal protective layer is chromium or platinum or other metals that can play a protective role.

Embodiment 3

[0058] It is basically the same as Example 1, the difference is:

[0059] In the fifth step of the preparation method of the above microsphere-based miniature hemispherical resonator gyroscope, the adhesive used is other adhesives such as hot melt adhesive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coefficient of expansion | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com