Biodegradable material and method for producing biodegradable material

A biodegradable, compound technology, used in drug delivery, pharmaceutical formulations, bandages, etc., can solve problems such as polymer particle deformation, and achieve the effects of improved biodegradability, improved shear strength, and improved recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0223] 10.0 g of branched chain polymer a1, 8-branched PEG (SUNBRIGHT (registered trademark) HGEO5000; manufactured by NOF Corporation) and hydroxycarboxylic acid a2, namely 22.0 g of lactide (PURASORB L; manufactured by PURAC BIOMATERIALS) were extracted. into an eggplant-shaped bottle. These were melt-mixed at 120° C. under an argon atmosphere, and 0.94 mL of tin (II) octoate toluene solution was added as a catalyst (tin (II) octoate (manufactured by Sigma-Aldrich Co.,) was dissolved in toluene (Wako Pure Chemical Industries, Ltd. Co., Ltd. (manufactured by Co., Ltd., adjusted to a concentration of 0.16 g / mL), a copolymerization reaction was performed under normal pressure for 20 hours to obtain an unpurified multi-component compound A1.

[0224] The obtained unrefined multi-component compound A1 was added dropwise to 100 mL of diethyl ether, and after the precipitate and liquid components separated from diethyl ether were collected, they were further washed with 50 mL of di...

Embodiment 2)

[0235] Change the amount of solution 1 to 0.199mL, change the amount of solution 2 to 0.450mL, change the amount of solution 3 to 0.351mL, change the amount of DMAP solution to 0.023mL, and change the amount of EDC to 0.040mL, Except for this, the same operation as in Example 1 was carried out to obtain the biodegradable membrane 2 and the acetonitrile-containing membrane 2 .

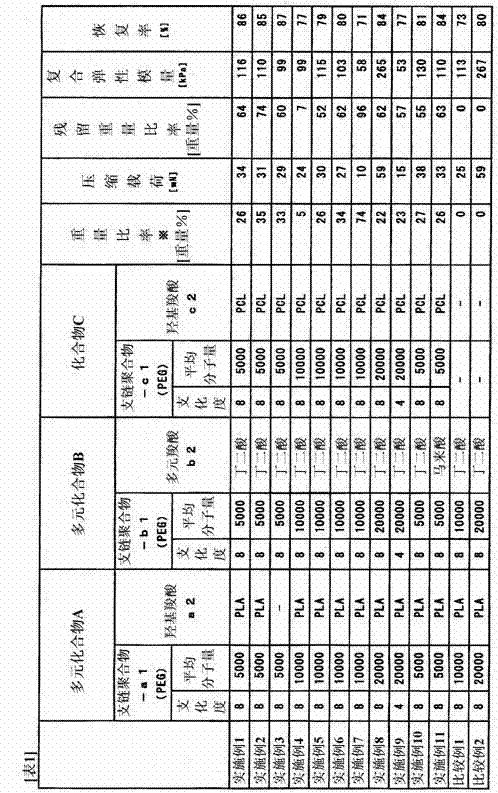

[0236] These biodegradable film 2 and acetonitrile-containing film 2 were evaluated in the same manner as in Example 1, and the results are shown in Table 1.

[0237] As shown in Table 1, the biodegradable film 2 had a large residual weight ratio, a large compressive load, and a high recovery rate. In addition, the composite elastic modulus of the acetonitrile-containing film 2 is large.

Embodiment 3)

[0239] Solution 4 was obtained in the same manner as in Example 1, except that multi-component compound A1 was changed to 8-branched PEG (SUNBRIGHT (registered trademark) HGEO5000; manufactured by NOF Corporation). The weight-average molecular weight of 8-branched PEG (SUNBRIGHT (registered trademark) HGEO5000; manufactured by NOF Corporation) measured by the GPC method was 5,000.

[0240] Change the amount of solution 1 from 0.295mL to 0.120mL of solution 4, change the amount of solution 2 to 0.555mL, change the amount of solution 3 to 0.325mL, change the amount of DMAP solution to 0.028mL, change the amount of EDC to Except for 0.049 mL, the same operation as in Example 1 was carried out to obtain the biodegradable membrane 3 and the acetonitrile-containing membrane 3 .

[0241] These biodegradable films 3 and acetonitrile-containing films 3 were evaluated in the same manner as in Example 1, and the results are shown in Table 1.

[0242] As shown in Table 1, the biodegradab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com