Electric wire stranding device and method, twisted cable manufacturing device and method

A cable manufacturing and wire technology, which is applied in the field of stranded cable devices, can solve the problems of time-consuming and inability to improve production efficiency, and achieve the effect of improving production efficiency and shortening production cycle time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

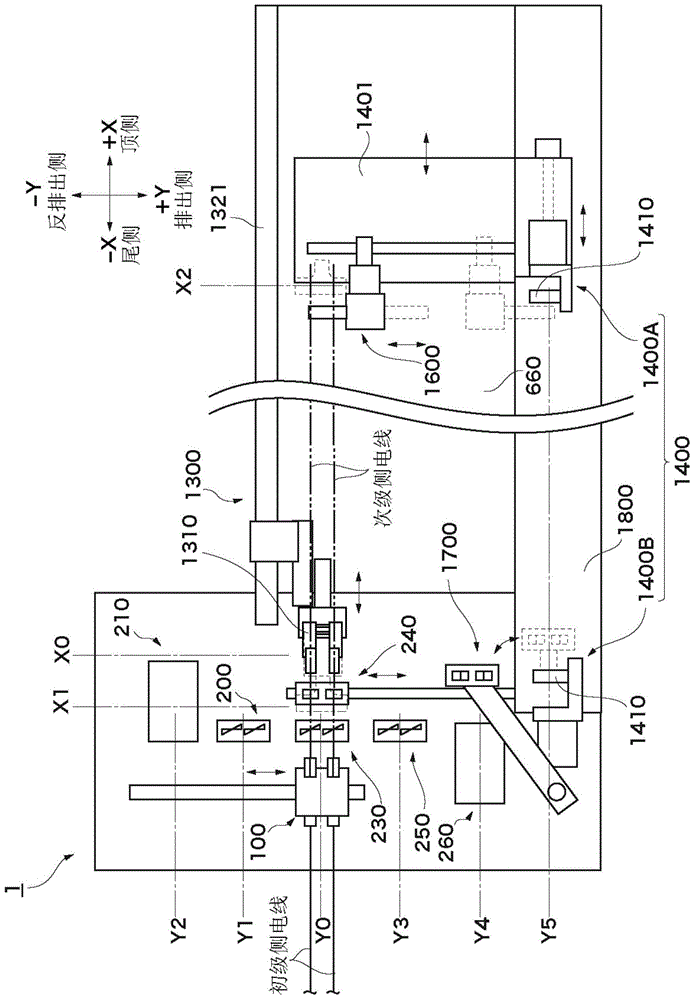

[0052] The overall structure of the stranded cable manufacturing device

[0053] refer to figure 1 , the overall structure of the stranded cable manufacturing device according to the embodiment of the present invention will be described. Twisted (twisted) cables pass through pairs Figure 23 The two electric wires W1 and W2 shown, which have been subjected to terminal treatment such as crimping terminals T at both ends, are obtained by twisting.

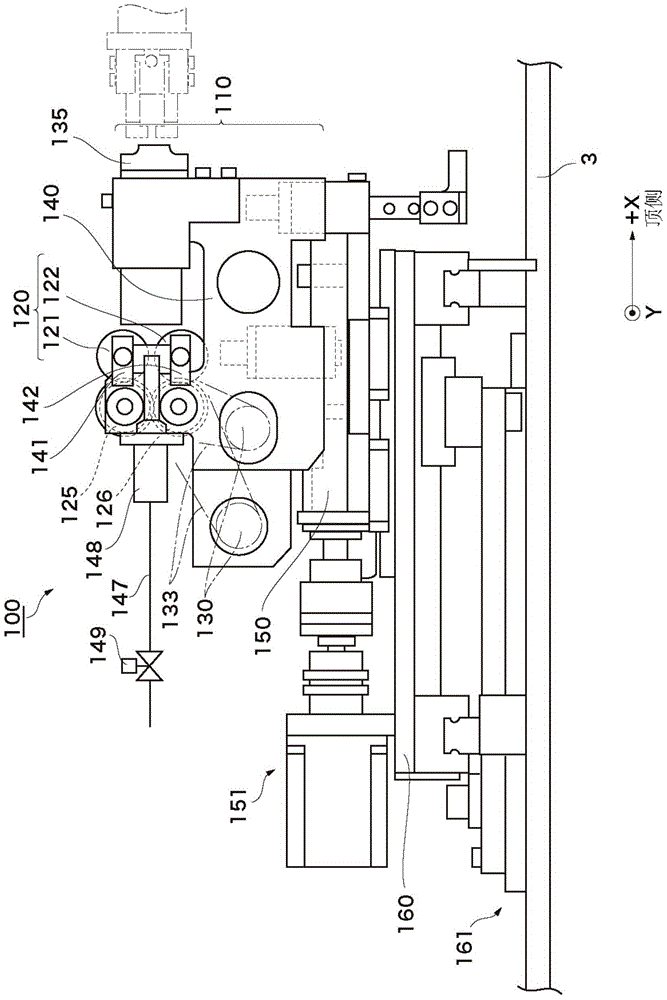

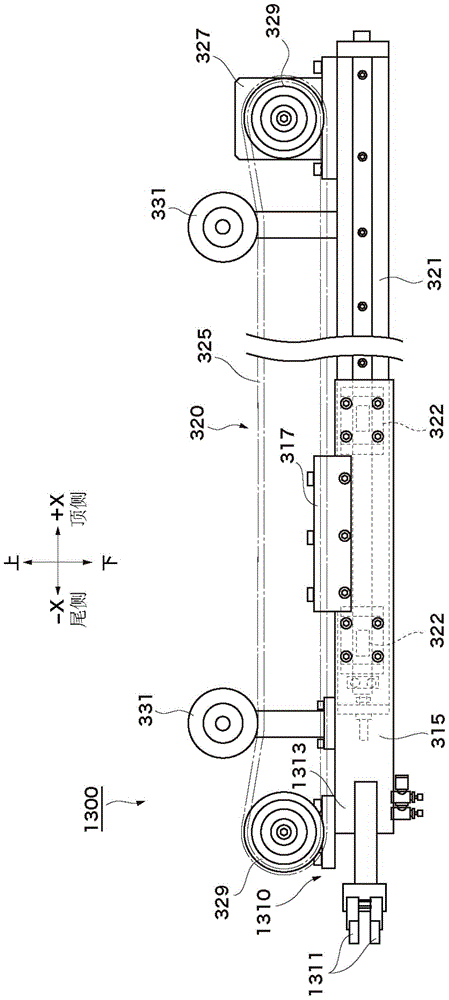

[0054] Such as figure 1 As shown, the twisted cable manufacturing device 1 has the following main parts: the electric wire supply device (mechanism) 100, which is used to separate from the two-wire type crimping wire manufacturing device (Japanese Patent No. Two wire bundles supply electric wires and clamp the front ends of the electric wires; a stripping device (mechanism) 200 for stripping the covering laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com