Wide-passage and equal-cross-section flow passage spiral plate type cooler

A technology of spiral plate type and equal cross-section, which is applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc., can solve the problems of shell-and-tube type with large footprint, large local resistance, easy scaling, etc., to achieve Improve the overall heat transfer coefficient, stabilize the flow rate, and prevent fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0026] The present invention will be described in detail below with reference to the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limitation on the protection scope of the present invention.

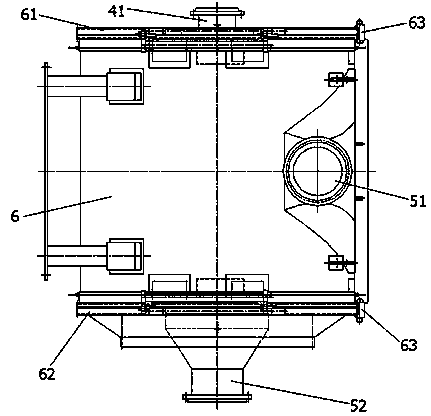

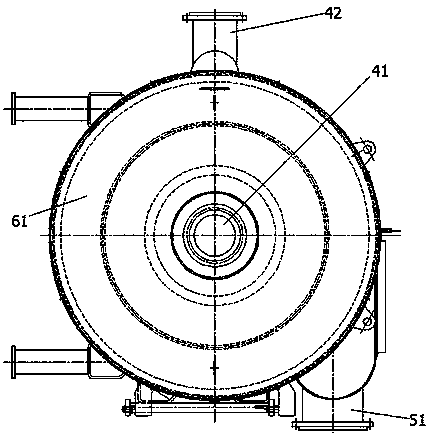

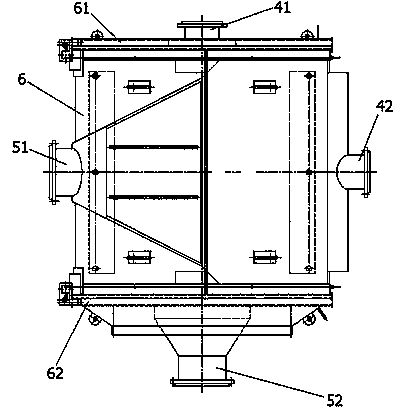

[0027] Such as Figure 1 to 6 The wide channel, uniform cross-section flow channel spiral plate cooler shown includes an inner roll body 1, a spiral plate 2 and a fixed-distance column 3. A cooling liquid channel 21 and a hot liquid channel 22 are formed between the spiral plates 2. The fixed-distance column 3 There are multiple, evenly distributed in the coolant channel 21 and the hot liquid channel 22,

[0028] The top of the inner roll body 1 is provided with a cold liquid inlet 11, and a number of side wall through holes 12 are opened around its side wall. The inner roll body 1 communicates with the cooling liquid channel 21 through each side wall through hole 12,

[0029] In the coolant channel 21, two adjacent rows of fixe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap