laser marking machine

A laser marking machine and laser transmitter technology, applied in the field of laser marking machines, can solve problems such as inability to precisely control processing accuracy, reduce work efficiency, and inability to carry out processing, so as to isolate the laser irradiation point from workers and reduce work-related injuries. Accidents, the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

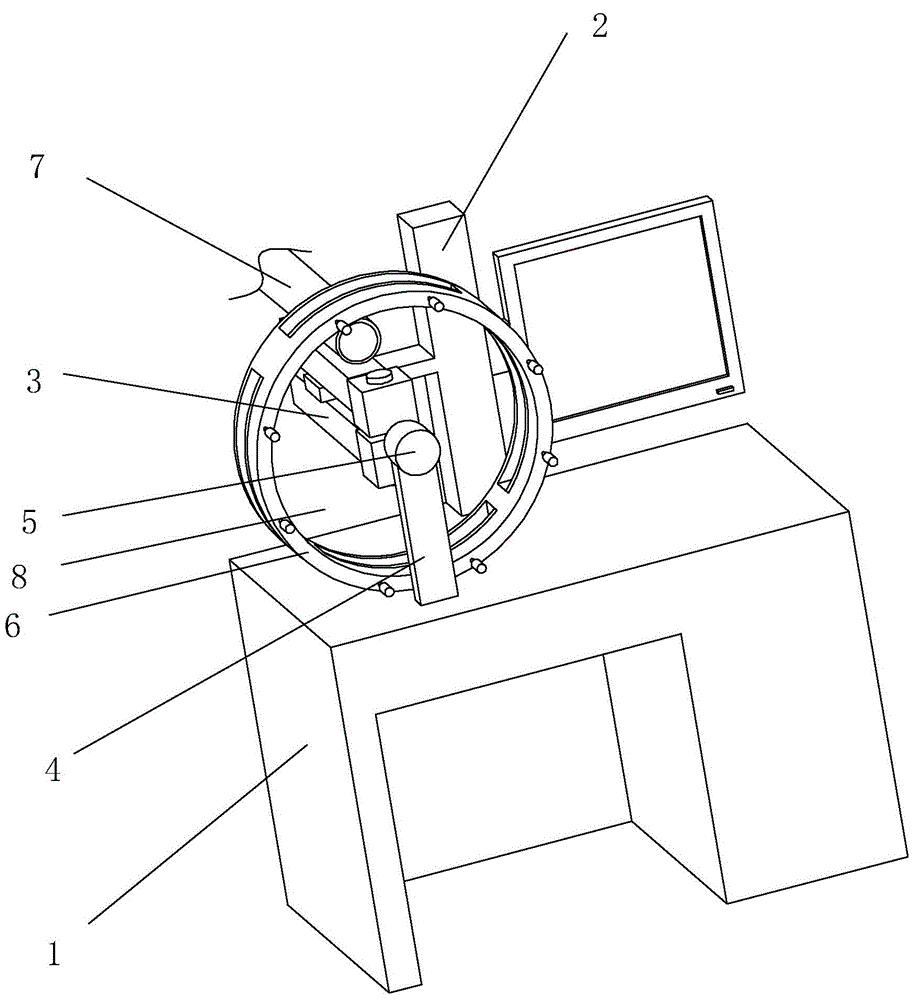

[0014] refer to Figure 1 to Figure 3 The embodiment of the laser marking machine of the present invention will be further described.

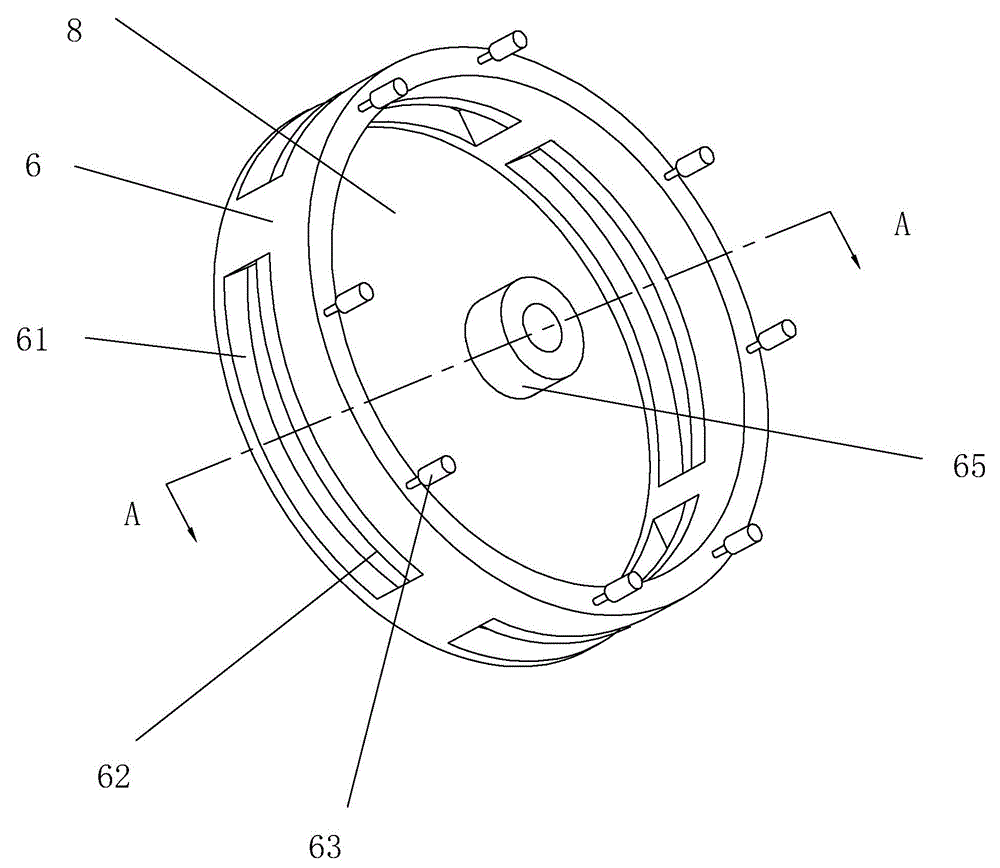

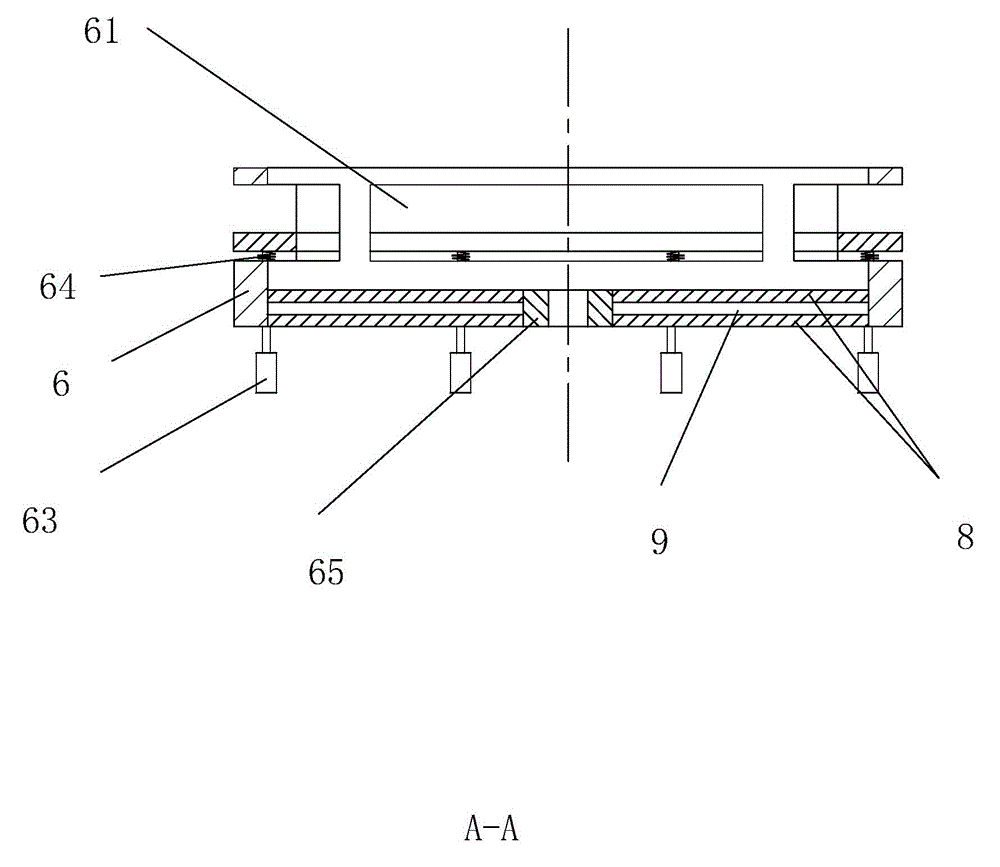

[0015] A laser marking machine, comprising a workbench 1 and a fixed column 2, the fixed column 2 is vertically fixed on the top of the workbench 1, and two laser emitters 3 are fixedly connected to the fixed column 2, and the two laser emitters The emission port of the device 3 is oppositely set, the laser emission direction is perpendicular to the workbench 1, the top of the workbench 1 is fixedly connected with a pillar 4, the pillar 4 is fixedly connected with a servo motor 5, and the servo motor 5 is fixedly connected There is a fixed disk 8, and the fixed disk 8 has at least 4 fixed fixtures in a circumferential array near the laser emitter 3. The fixed fixtures are all set opposite to the laser emitter 3, and the workpiece is clamped on the fixed fixture. The motor 5 rotates at a fixed angle so that the two unprocessed workpieces close...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com