A kind of sapphire crystal guided mode growth device and growth method

A sapphire crystal and growth device technology, applied in the field of crystal manufacturing, can solve problems affecting the crystal interface, pollution of new raw materials, material corrosion, etc., and achieve the effect of improving crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

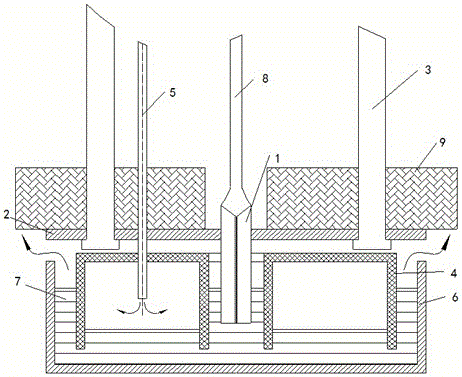

[0035] Such as figure 1 As shown, the present invention discloses a sapphire crystal guided mode growth device, comprising a crystal growth furnace, which has an outer crucible 6 for loading alumina solution 7, and one placed above the crucible mouth of the outer crucible 6 and connected with the A hanging plate 2 fitted to the mouth of the crucible and an inner crucible 4 placed upside down in the outer crucible 6;

[0036] A mold 1 is installed at the center of the hanging pan 2, and the circumference of the hanging pan 2 is evenly distributed in a ring shape with a number of suspenders 3 that drive the hanging pan 2 to move up and down, and an insulating carbon blanket layer 9 is laid on the upper surface of the hanging pan 2;

[0037] The crucible bottom of the inner crucible 4 is provided with a ventilation pipe 5 for blowing liquid discharge gas into the inner crucible, and through the ventilation pipe 5, the inner crucible 4 is fixed under the hanging plate 2, and the ...

Embodiment 2

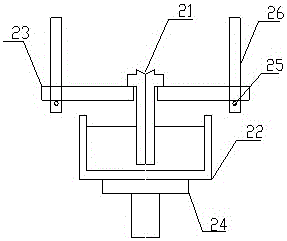

[0043] Such as figure 2 As shown, the present embodiment is based on the embodiment 1. In the sapphire crystal guided mode growth device, the inner crucible 4 is coaxially inverted in the outer crucible 6, and the center position of the crucible bottom of the inner crucible 4 has a mold extension. The mold limit sleeve 10 that is inserted into and communicated with the bottom of the crucible of the inner crucible 4; the bottom of the crucible of the inner crucible 4 is provided with a vent pipe installation hole 11, and the vent pipe installation hole 11 is a threaded hole, and the vent pipe 5 is fixed on the The vent tube is installed in the hole.

[0044] In this embodiment, the inner crucible 4 is coaxially inverted in the outer crucible 6, which facilitates and effectively controls the height of the liquid level of the melt, so that the height of the liquid level of the melt remains unchanged; The limit is in the mold limit sleeve 10, so that the crystal grows stably; th...

Embodiment 3

[0046] In this embodiment, on the basis of Embodiment 1, in the sapphire crystal guided mode growth method, a mixed protective gas of Ar, CO and CO is introduced into the thermal field. 2 of mixed gas.

[0047] In this embodiment, the mixed protective gas can effectively inhibit the evaporation of alumina at 2100 to 2200 degrees, and can also effectively prevent the evaporated alumina vapor from reacting with other graphite materials in the thermal field, and also reduce the interaction between graphite materials and The degree of reaction between the mold 1 and the Mo / W metal such as the crucible in the thermal field, because the conductive film method uses a graphite material insulation system, and the system is in a high temperature environment above 2100 degrees, the reaction equation of the position where the graphite contacts the metal is as follows:

[0048] W + C = WC[1]

[0049] Mo + C = Mo 3 C [2]

[0050] Considering the evaporation of alumina, C, Mo and W,

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com