Self-locking mechanism

A technology of self-locking and locking blocks, which is applied in the direction of supporting machines, mechanical equipment, machine platforms/supports, etc., which can solve the problems that small-pitch screens cannot be disassembled with tools, and sky screens are difficult to disassemble, so as to achieve convenient and fast disassembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

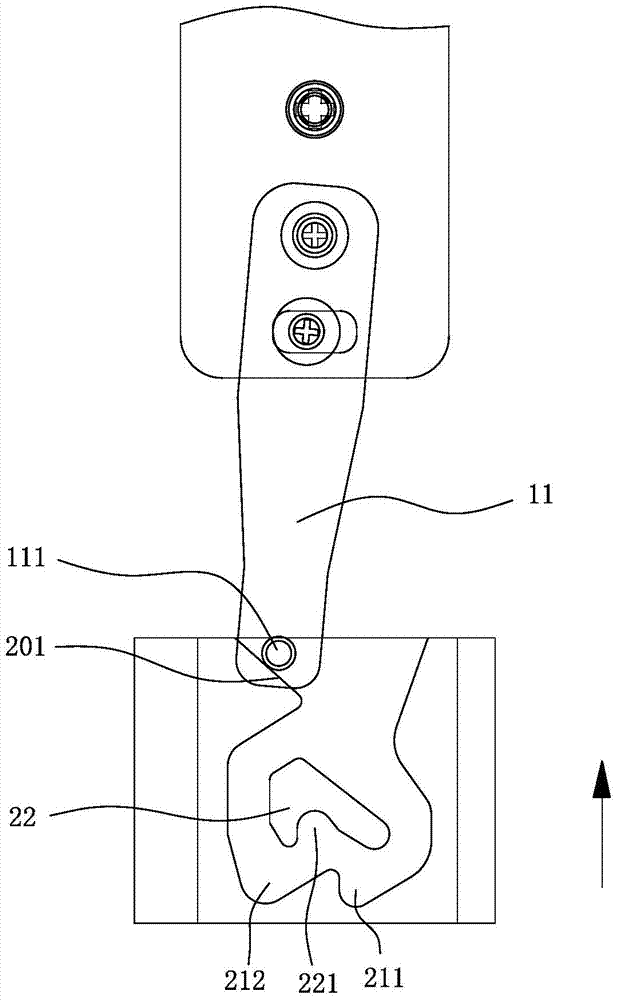

[0023] Below in conjunction with accompanying drawing and embodiment the present invention will be described in further detail, wherein Figure 3~Figure 9 The arrow direction in indicates the movement direction of the self-locking member.

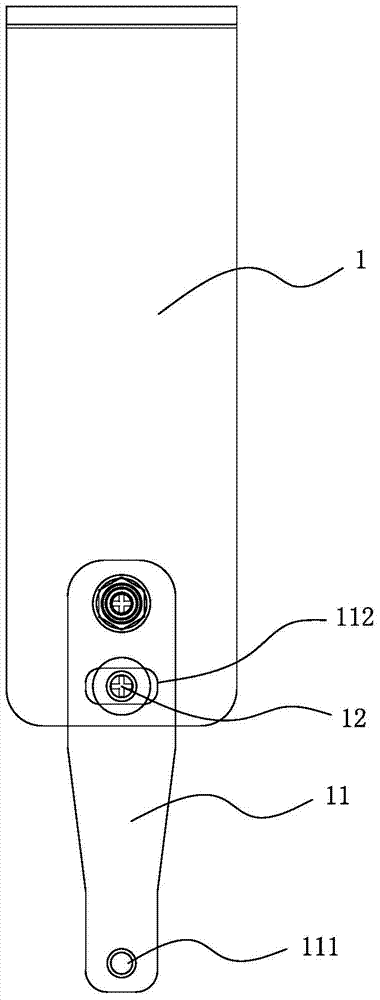

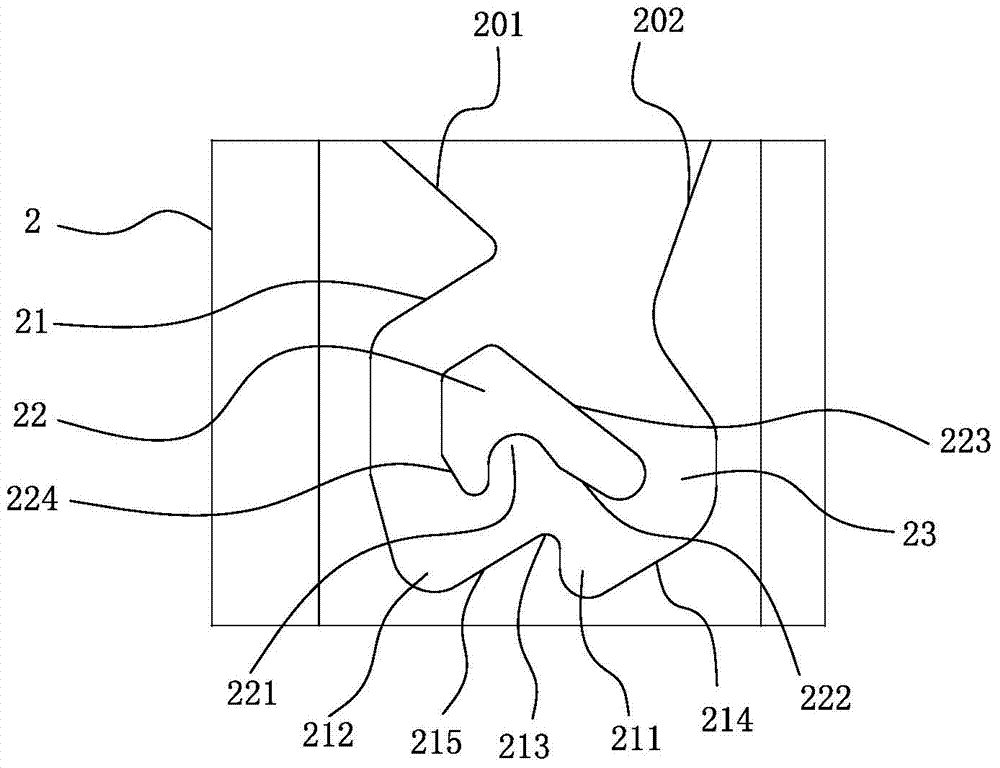

[0024] refer to Figure 1 to Figure 9 , a self-locking mechanism of the present invention, including a fixed frame 1 and a self-locking member 2, the fixed frame 1 is installed on the ceiling, and it is rotatably installed with a connecting piece 11, and the lower end of the connecting piece 11 is provided with a hanging rod 111 The self-locking member 2 is installed on the module, and a special-shaped groove 21 with an open upper end is provided in it, and the lower end of the special-shaped groove 21 is provided with a first limiting groove 211 and a second limiting groove 212, and the special-shaped groove 21 is provided with a There is a lock block 22, and a guide channel 23 is formed between the outer periphery of the lock block 22 an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap