Protection circuit of high voltage circuit breaker energy storage drive motor

A high-voltage circuit breaker and driving motor technology, applied in emergency protection circuit devices, electrical components and other directions, can solve the problems affecting the normal operation of the circuit breaker, circuit breaker failure, idling of the energy storage drive motor, etc., to shorten the maintenance time and cost, Guaranteed reliability and easy-to-achieve results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

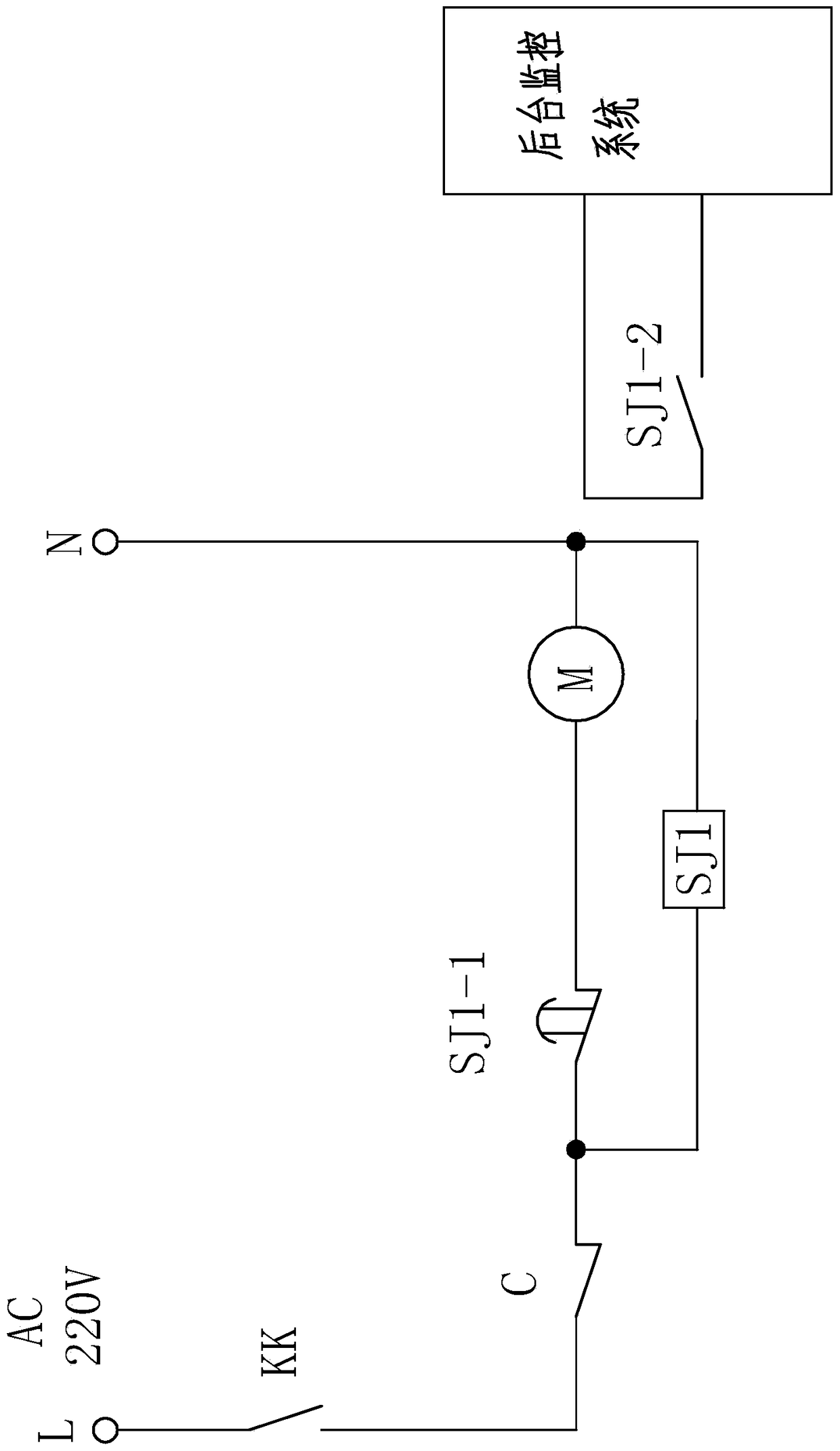

[0014] see figure 1 The protection circuit of the high-voltage circuit breaker energy storage drive motor of this embodiment is mainly composed of the air switch KK set in the high-voltage circuit breaker, the energy storage limit normally closed contact C, the energy storage drive motor M, and the remote The background monitoring system and the time relay SJ1 set in the high-voltage circuit breaker are composed.

[0015] The time relay SJ1 has a coil, a delayed open normally closed contact SJ1-1 and a normally open contact SJ1-2.

[0016] One end of the air switch KK is electrically connected to the live wire L of the 220V AC power supply; the other end of the air switch KK is electrically connected to one end of the energy storage limit normally closed contact C; the other end of the energy storage limit normally closed contact C is connected to the time The wire-in end of the coil of relay SJ1 and one end of the time relay SJ1's delayed open normally closed contact SJ1-1 are in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com