A method for preparing magnetic flocculant by compounding fly ash magnetic beads and polyacrylamide

A polyacrylamide and magnetic flocculant technology, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, magnetic field/electric field water/sewage treatment, etc., to achieve uniform distribution of micro-magnetic beads, wide source of raw materials, clear environment benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1. Preparation of strong magnetic micro-magnetic beads

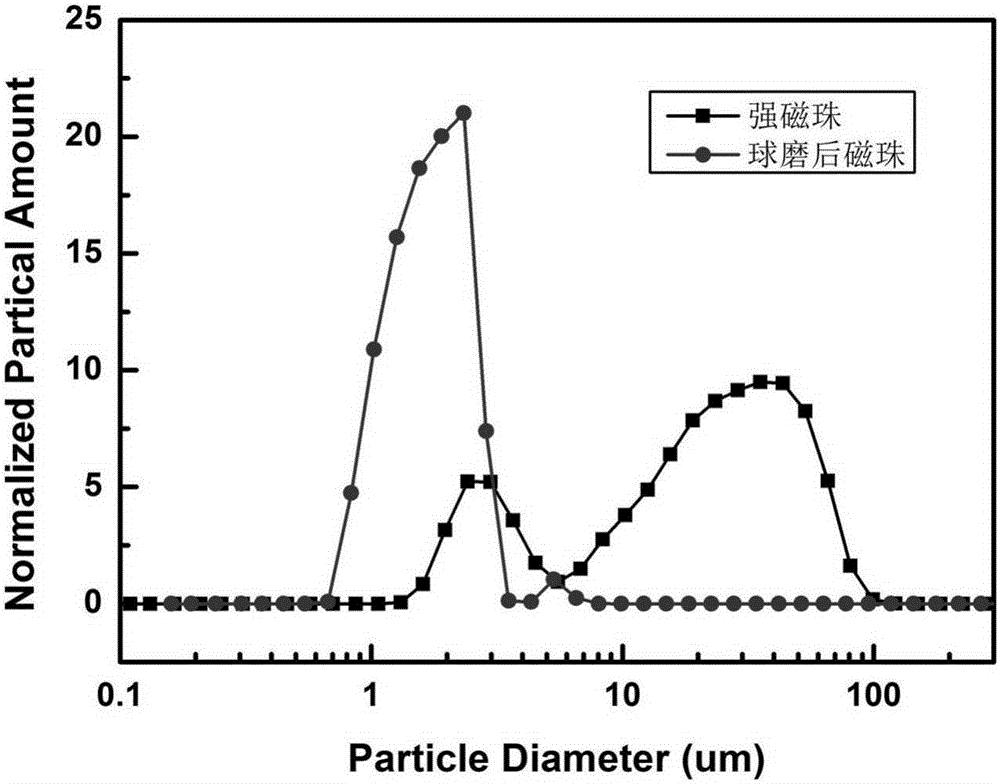

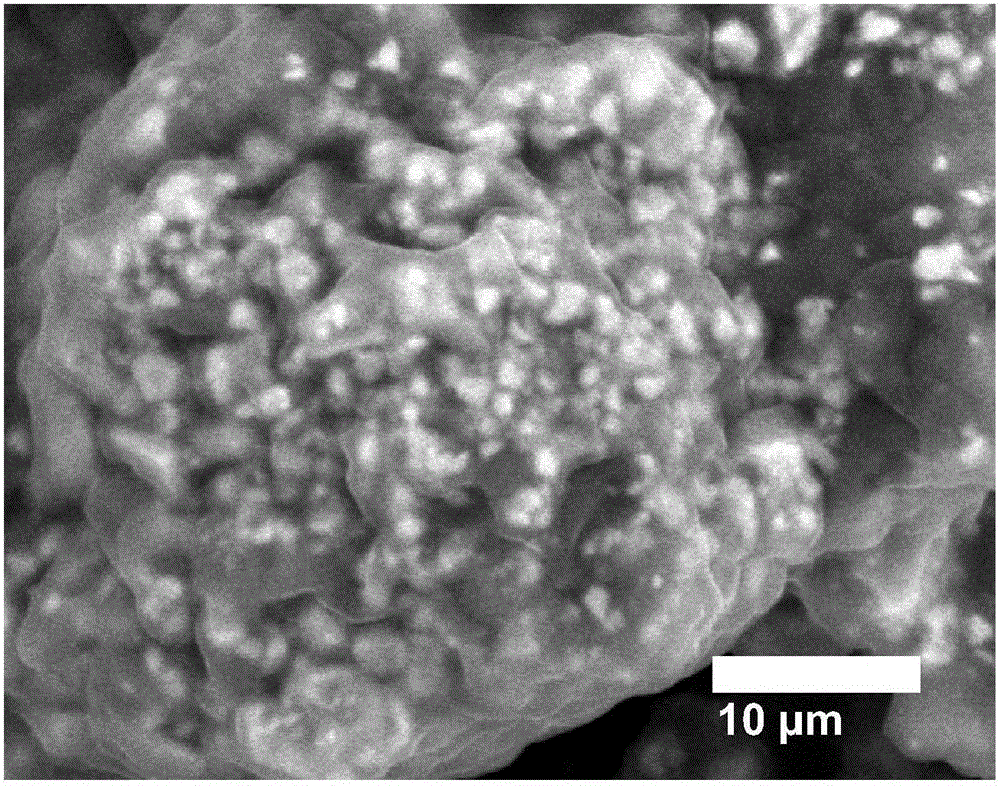

[0025] Weigh 100g of fly ash, dry it fully, first remove the residual carbon particles through a high-voltage electric separator, and then use a magnetic separation tube to perform magnetic separation under a magnetic field of 300mT to obtain the magnetic microbeads contained in the fly ash , and then the magnetic beads obtained are subjected to magnetic separation for 3 times under a magnetic field of 50mT to obtain strong magnetic beads; in the obtained strong magnetic beads, add 5% magnetite of strong magnetic beads quality powder (-200 mesh), then use zirconia ceramic balls as the grinding medium, and use sodium chloride as the protective salt, and ball mill for 4 hours at a speed of 100 rpm. Magnetic separation is carried out under a strong magnetic field to remove the weak magnetic and non-magnetic components, and obtain strong magnetic micro-magnetic beads with an average particle size of <5 μm.

[0026] 2...

Embodiment 2

[0033]Use pure polyacryloyl (12 million cationic) and the micro-magnetic beads / polyacrylamide magnetic flocculant prepared by the present invention as flocculants respectively for the simulated kaolin sewage (kaolin particle size-600 mesh, concentration: mass fraction 3%) to carry out the sedimentation treatment experiment. As a result, it was found that the clarification effect and efficiency of the magnetic flocculant of the present invention were improved compared with pure polyacrylamide without an external magnetic field, the turbidity was reduced by 16%, the settling velocity was increased by 25%, and the volume of tailings was reduced by 18%; After adding the external magnetic field, the sedimentation rate increased to 62%, the tailings volume decreased by 55%, the turbidity decreased basically unchanged, and the sewage treatment effect and efficiency were greatly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com