Venturi mist sprayer

A technology of venturi and mist sprayer, applied in the field of dust control equipment, can solve the problems of limited coverage area, limitation, limited volume of a single water mist particle, etc., and achieve the effect of improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

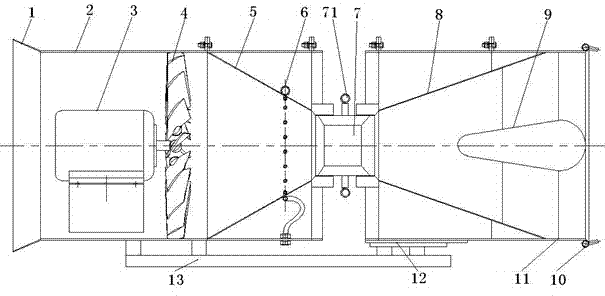

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

[0013] Such as figure 1 The shown Venturi sprayer includes an air inlet pipe 2, a motor 3, an impeller 4, a Venturi shrinkage pipe 5, a Venturi throat pipe 7 and a Venturi diffusion pipe 8,

[0014] A collecting cover 1 is installed at the port of the air inlet pipe, and the impeller 4 and the Venturi shrinkage pipe 5 are installed in the air inlet pipe 2. One end of the pipe 7 is connected, and the end with a larger diameter faces the impeller 4. A micro-mist nozzle 6 is installed at the end of the Venturi shrinkage pipe 5 with a smaller diameter. There are several micro-mist nozzles 6, and the number can be determined according to the actual situation. The end distribution, the impeller 4 is connected with the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com