Tube-fin flat plate collector

A flat-plate collector and tube-fin technology, which is used in solar collectors, solar collectors using working fluids, heating devices, etc., can solve the problem that the vacuum tube solar water heating system cannot be perfectly combined and completely sealed, etc. problem, to achieve the effect of low cost, poor weather resistance and high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

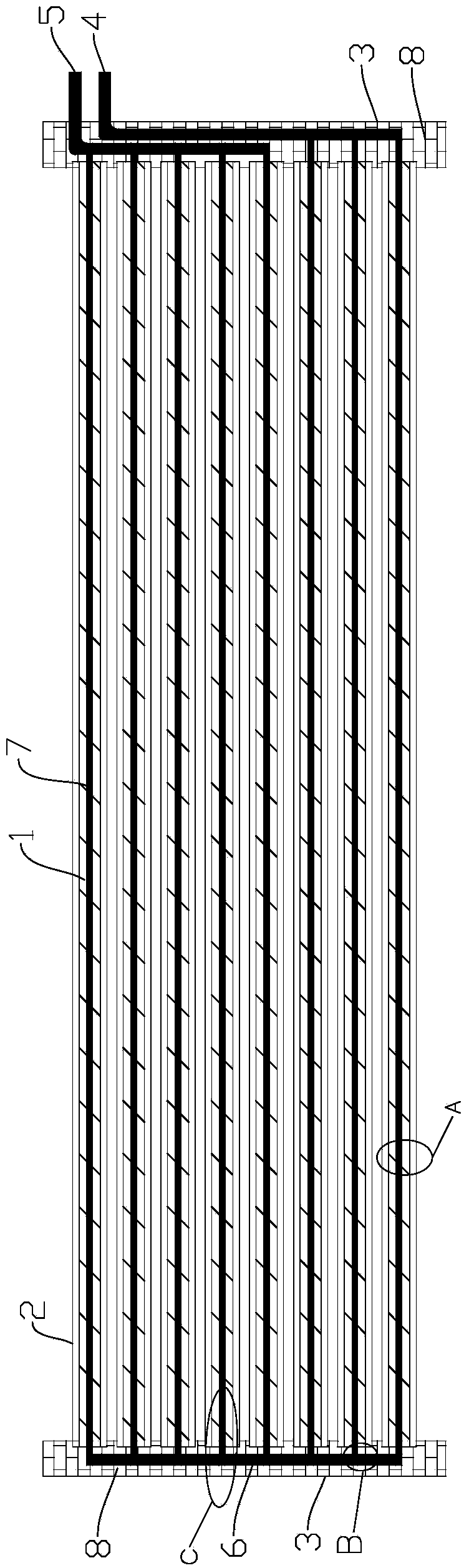

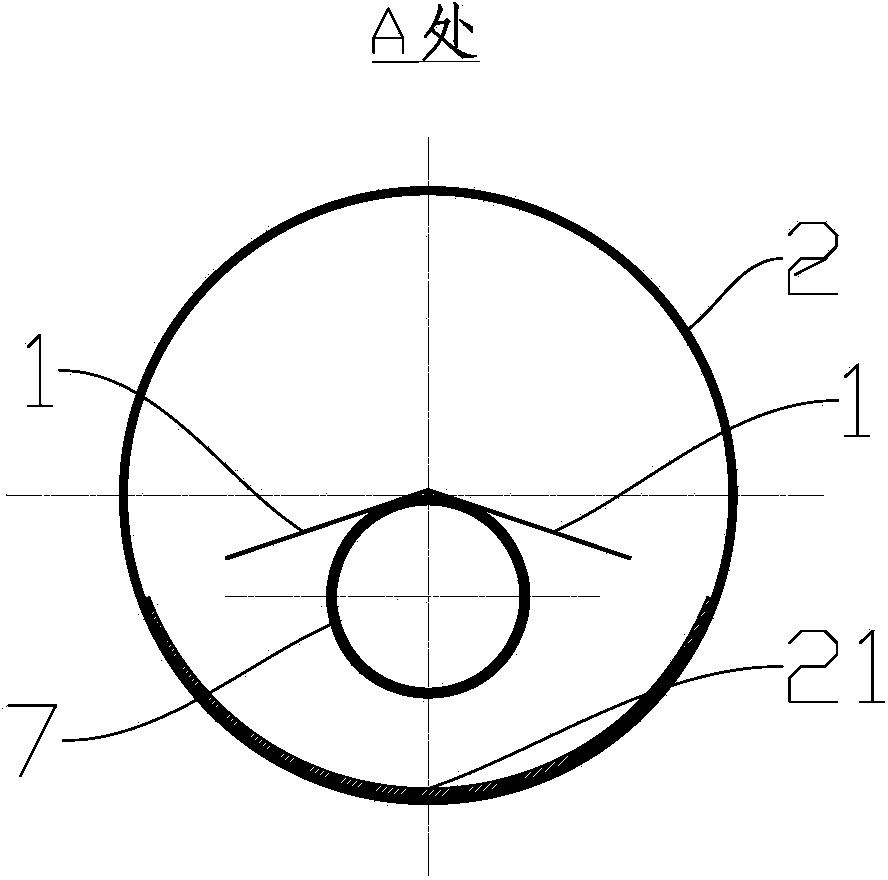

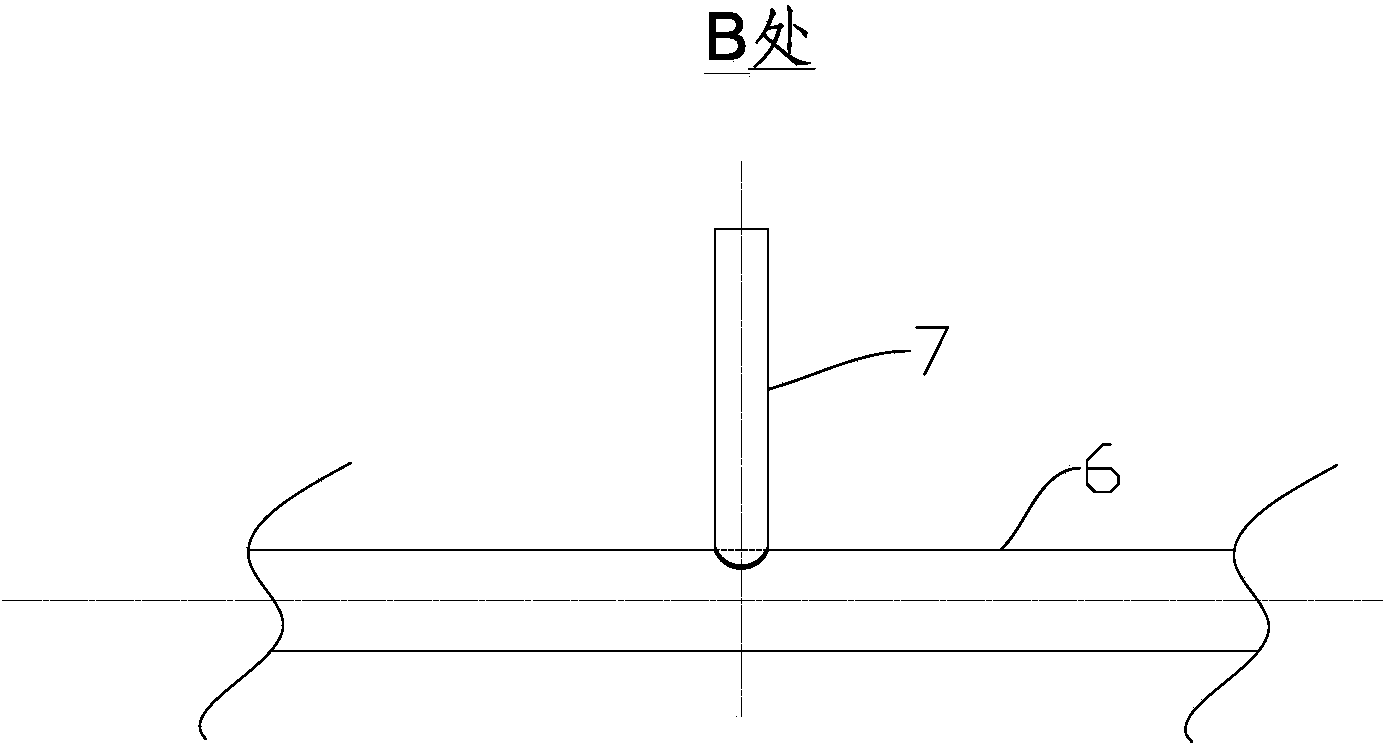

[0034] Such as figure 1 As shown, the tube-fin flat plate collector includes a heat absorbing plate 1, a flow channel, a cover glass tube 2, and a frame 3. The water inlet pipe 4, the water outlet pipe 5, the connecting pipe 6 and the branch pipe 7 constitute the flow channel.

[0035] One end of the branch pipe 7 communicates with the connecting pipe 6 , and the other end communicates with the water inlet pipe 4 / water outlet pipe 5 .

[0036] The heat absorbing plate 1 is welded on the branch pipe 7, and the heat absorbing plate 1 and the branch pipe 7 are fused to reduce thermal resistance as the main purpose, and resistance welding, plasma welding, argon arc welding, laser welding and other methods can be used. The length direction of the heat absorbing plate 1 is parallel to the axis of the branch pipe 7 . Both the front and the back of the heat absorbing plate 1 are provided with selective absorbing coatings, which can be prepared by chemical methods, magnetron sputter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com