Yogurt stabilizer and method for preparing low-temperature yogurt using it

A stabilizer and yogurt technology, which is applied in the field of yogurt stabilizer and its use to prepare yogurt, can solve the problems of food safety hazards, complicated production process, complex production process, etc. The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Stabilizer compounding: Weigh 400g of commercially available lotus root starch and use it as a stabilizer for low-temperature yogurt for later use.

[0048] (1) Dissolving: Add 1600g fresh milk (commercially available, 3.2 wt% fat, 2.95 wt% protein, 8.1wt% non-fat milk solids, acidity 14) to 400g stabilizer o T), mix evenly to dissolve the stabilizer, stir until there are no lumps, and then mix the milk;

[0049] (2) Gelatinization: Take 4kg of fresh milk and heat it to 70°C, add the mixed milk obtained in step (1) while stirring, keep it at 70°C for 5 minutes until gelatinization, and obtain 6kg of gelatinized milk;

[0050] (3) Mixing ingredients: Add 6kg of gelatinized milk, 3.2kg of fresh milk and 800g of white sugar obtained in step (2) into the mixing tank, and stir evenly;

[0051] (4) High-speed shearing: put the milk mixed and prepared in step (3) in a high-speed shearing machine, and shear at a speed of 2000 rpm for 5 minutes;

[0052] (5) Homogenization: He...

Embodiment 2

[0059] Stabilizer compounding: Weigh 300g of commercially available rice flour (expanded), 200g of lotus root powder, 500g in total, mix well, and use as a stabilizer for low-temperature yogurt for later use.

[0060] (1) Dissolving: Add 500g fresh milk (commercially available, 3.3 wt% fat, 3.1 wt% protein, 8.3 wt% non-fat milk solids, acidity 15% to 500g stabilizer o T), mix evenly to dissolve the stabilizer, stir until there are no lumps, and then mix the milk;

[0061] (2) Gelatinization: take 3kg of fresh milk and heat it to 90°C, add the mixed milk obtained in step (1) while stirring, keep it at 90°C for 10 minutes until gelatinization, and obtain 4kg of gelatinized milk;

[0062] (3) Mixing ingredients: Add 4kg of gelatinized milk, 5.2kg of fresh milk and 800g of white sugar obtained in step (2) into the mixing tank, and stir evenly;

[0063] (4) High-speed shearing: put the milk mixed and prepared in step (3) in a high-speed shearing machine, and shear at a speed of 20...

Embodiment 3

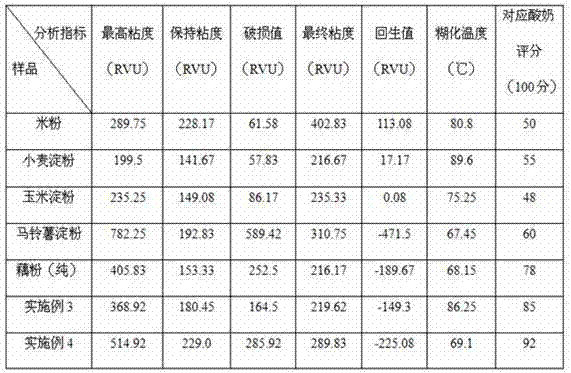

[0071] Stabilizer compounding: Weigh 30g of commercially available wheat starch, 60g of potato starch, 60g of rice flour, and 150g of lotus root starch, totaling 300g, mix well, and use it as a stabilizer for low-temperature yogurt.

[0072] (1) Dissolving: Add 300g fresh milk (commercially available, 3.25 wt% fat, 3.0 wt% protein, 11 wt% non-fat milk solids, acidity 16) to 300g stabilizer o T), mix evenly to dissolve the stabilizer, stir until there are no lumps, and then mix the milk;

[0073] (2) Gelatinization: take 3kg of fresh milk and heat it to 80°C, add the mixed milk obtained in step (1) while stirring, keep it at 80°C for 15 minutes until gelatinization, and obtain 3.6kg of gelatinized milk;

[0074] (3) Mixing ingredients: Add 3.6kg of gelatinized milk, 5.6kg of fresh milk and 800g of white sugar obtained in step (2) into the mixing tank, and stir evenly;

[0075] (4) High-speed shearing: put the milk mixed and prepared in step (3) in a high-speed shearing machine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water separation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap