A Symmetrical Translational Differential Mechanism

A differential mechanism and symmetrical technology, applied in the stacking of objects, unstacking of objects, loading/unloading, etc., can solve problems such as increased defective rate, easy collision, brick damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

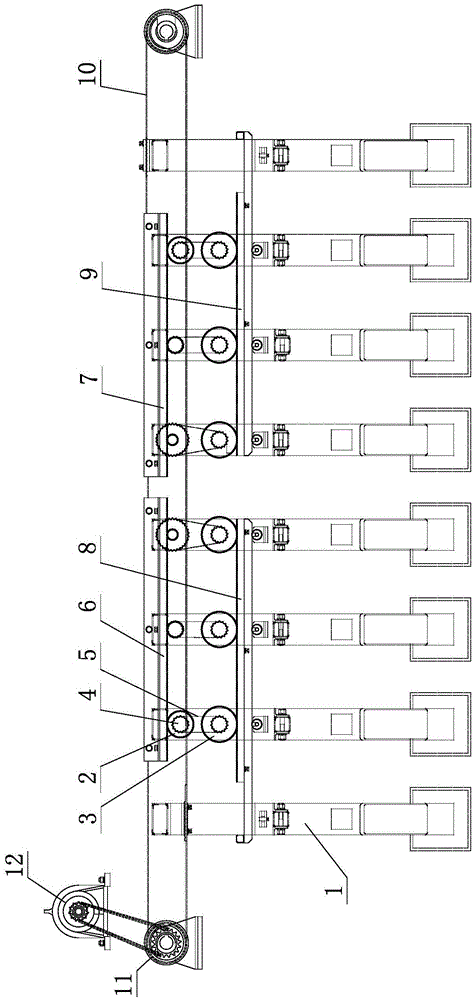

[0010] Such as figure 1 As shown, a symmetrical translational differential mechanism includes several collets 1 spaced side by side from front to back, and upper gears 2 and lower gears 3 are respectively arranged on both sides of each collet 1 at intervals up and down. The upper gear 2 and the lower gear 3 are respectively connected by the coaxial sprocket 4 through the chain 5, and the upper side of each upper gear 2 on the same side of the chuck 1 is provided with two spaced front fixed racks 6 and rear fixed racks. 7. The front fixed rack 6 meshes and connects with the upper gears 2 on the side of several chucks 1 on the corresponding front side. The bar 7 meshes with the upper gears 2 on the side of several collets 1 on the corresponding rear side. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com