Method and device for preparing functionally graded structural component

A technology for functionally gradient and structural parts, applied in the field of preparing functionally graded structural parts, can solve the problems of difficulty in recycling, can not meet the diversification of product performance, waste powder, etc., and achieve the effect of easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0037] Example one

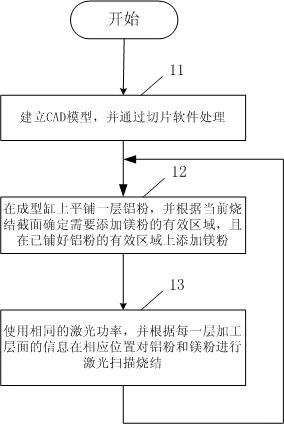

[0038] Such as figure 1 As shown, the method for preparing a functionally graded structure includes the following steps:

[0039] Step 11: Establish a three-dimensional solid CAD model of the structural part, and obtain the information of each layer of processing through the slice software processing;

[0040] Step 12: The forming cylinder is lowered by one layer thickness, and a layer of aluminum powder (melting point is 660.2℃) is spread on the forming cylinder so that the plane of the aluminum powder is flush with the working plane of the forming cylinder; and the need is determined according to the current sintering section Add the effective area of magnesium powder (melting point is 650℃), and add magnesium powder on the effective area where the aluminum powder has been paved. The height of the added magnesium powder is calculated according to the mass ratio of the aluminum powder to the magnesium powder in the effective area get;

[0041] In this step, th...

Example Embodiment

[0054] Example two

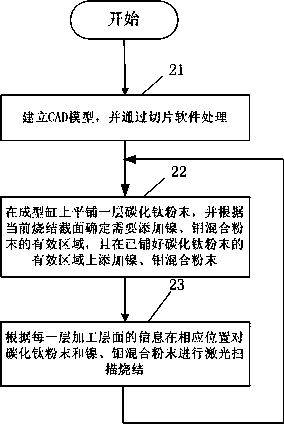

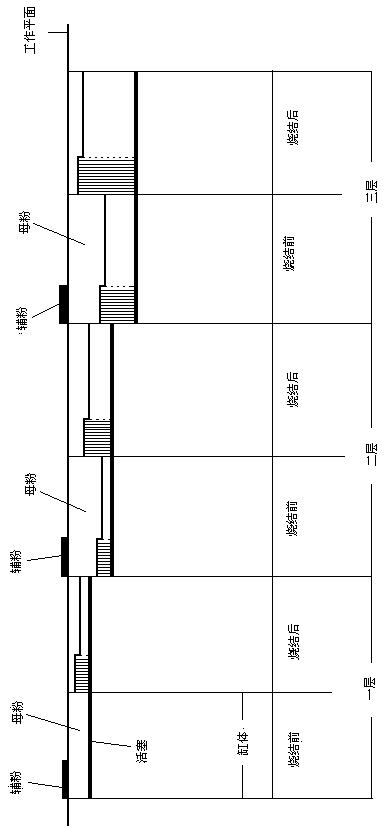

[0055] image 3 It is the method flow chart of Embodiment 2 provided by the method for preparing a functionally graded structure of the present invention, Figure 4 Is a cross-sectional view of the circular piston structure prepared by the method in Example 2, such as image 3 As shown, the method for preparing a functionally graded structure includes the following steps:

[0056] Step 21: Establish a three-dimensional solid CAD model of the structure, and obtain the information of each layer of processing through the slice software processing;

[0057] Step 22: The forming cylinder is lowered by a layer thickness, and a layer of titanium carbide powder is spread on the forming cylinder so that the plane of the titanium carbide powder is flush with the working plane of the forming cylinder; and the need to add nickel, The effective area of the molybdenum mixed powder, and the nickel and molybdenum mixed powder is added to the effective area where the titanium c...

Example Embodiment

[0069] Example three

[0070] Such as Figure 5 As shown, the device for preparing a functionally graded structure includes:

[0071] The slicing unit 31 is used to process the built three-dimensional solid CAD model to obtain the information of each processing level;

[0072] The powder spreading unit 32 is used to spread a layer of master powder on the working plane and add auxiliary powder on the effective area where the master powder has been spread;

[0073] The processing unit 33 determines the effective area where auxiliary powder needs to be added in the current sintering section, and calculates the height of the added auxiliary powder according to the mass ratio of the mother powder to the auxiliary powder in the effective area; and

[0074] The scanning unit 34 is used for laser scanning and sintering the master powder and auxiliary powder at the corresponding position according to the information of the processing level of each layer.

[0075] In specific implementation, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap