A special castable for 5000t cement kiln coal injection pipe

The technology of castable and coal injection pipe is applied in the field of high-temperature materials for building materials, which can solve the problems of poor workability, segregation of castables, and many pores, etc., and achieve the effects of improving corrosion resistance, improving thermal shock resistance and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

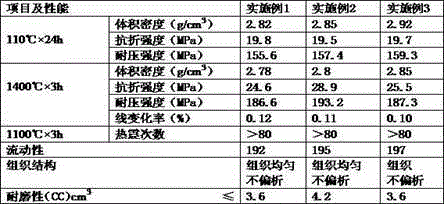

Examples

Embodiment 1

[0059] A special castable for 5000T cement kiln coal injection pipe, the weight percentage of the components contained in it is:

[0060] Zinc-aluminum spinel 25%

[0061] Synthetic moissanite 20%

[0062] Brown fused alumina 25%

[0063] Strontium titanate powder 8%

[0064] Zirconium carbonate powder 5%

[0065] Andalusite powder 1%

[0067] Aluminum oxide powder 5%

[0068] Pure calcium aluminate cement 6%

[0070] C 5 h 10 N 6 o 2 0.2%

[0071] Heat-resistant steel fiber 0.5%

[0072] Sulfonated styrene-maleic anhydride copolymer 0.05%

[0073] Polyether polycarboxylic acid 0.1%

Embodiment 2

[0075] A special castable for 5000T cement kiln coal injection pipe, the weight percentage of the components contained in it is:

[0076] Zinc-aluminum spinel 15%

[0077] Synthetic moissanite 20%

[0078] Brown fused alumina 30%

[0079] Strontium titanate powder 10%

[0080] Zirconium carbonate powder 8%

[0081] Andalusite powder 2%

[0082] Zinc silicate 3%

[0083] Aluminum oxide powder 5%

[0084] Pure calcium aluminate cement 6%

[0085] Terbium oxide 1%

[0086] C 5 h 10 N 6 o 2 0.2%

[0087] Heat-resistant steel fiber 0.5%

[0088] Sulfonated styrene-maleic anhydride copolymer 0.05%

[0089] Polyether polycarboxylic acid 0.1%.

Embodiment 3

[0091] A special castable for 5000T cement kiln coal injection pipe, the weight percentage of the components contained in it is:

[0092] Zinc aluminum spinel 20%

[0093] Synthetic moissanite 15%

[0094] Brown fused alumina 30%

[0095] Strontium titanate powder 10%

[0096] Zirconium carbonate powder 8%

[0097] Andalusite powder 2%

[0098] Zinc silicate 3%

[0099] Aluminum oxide powder 5%

[0100] Pure calcium aluminate cement 5%

[0101] Terbium oxide 2%

[0102] C 5 h 10 N 6 o 2 0.2%

[0103] Heat-resistant steel fiber 0.5%

[0104] Sulfonated styrene-maleic anhydride copolymer 0.05%

[0105] Polyether polycarboxylic acid 0.1%

[0106] Tc 2 o 7 0.05.

[0107] The components used in the above examples are products well known to those skilled in the art and can be purchased in the market. The addition of synthetic moissanite, strontium titanate, brown corundum, and steel fibers is beneficial to the wear resistance of the castable andalusite has micro-e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com