Control structure of heating chamber of steel ball reheating furnace

A technology for controlling structures and heating chambers, applied in heat treatment furnaces, furnaces, manufacturing tools, etc., can solve the problem that the consistency of the heating effect of steel balls is difficult to control, and achieve the effect of good consistency and guaranteed cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0017] The embodiments of the present invention will be described in detail below with reference to the drawings.

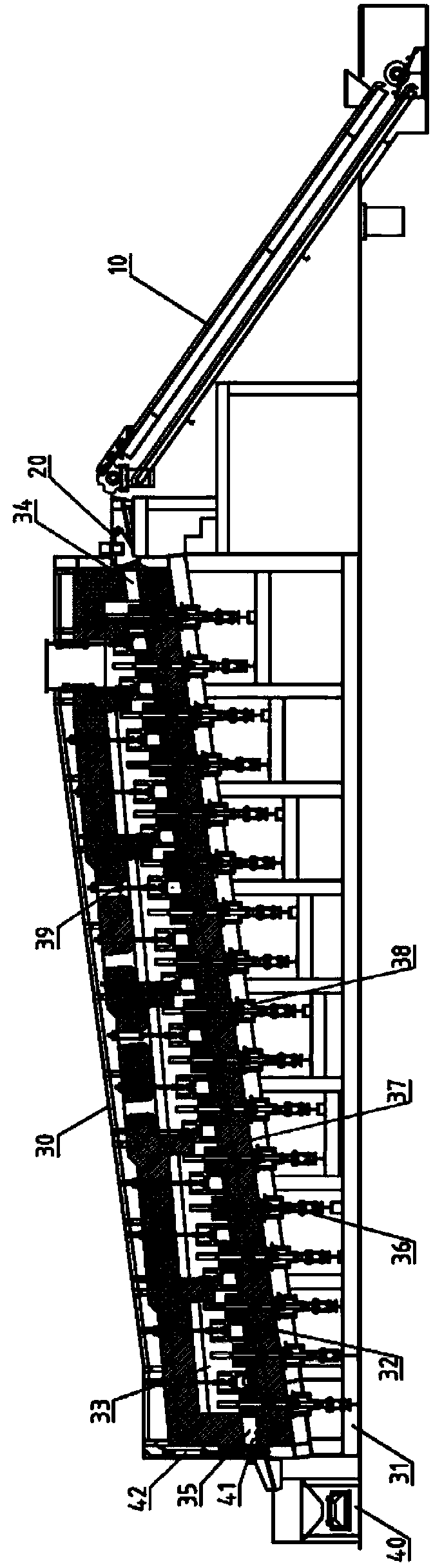

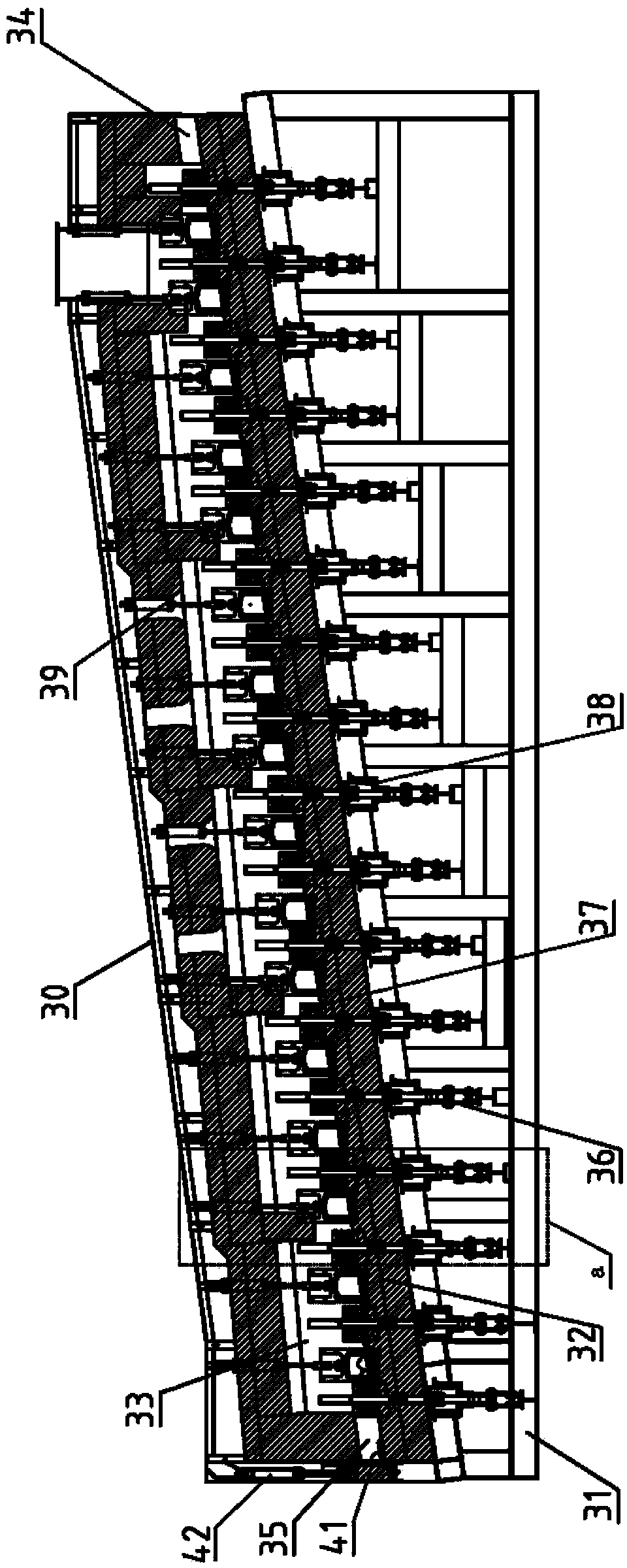

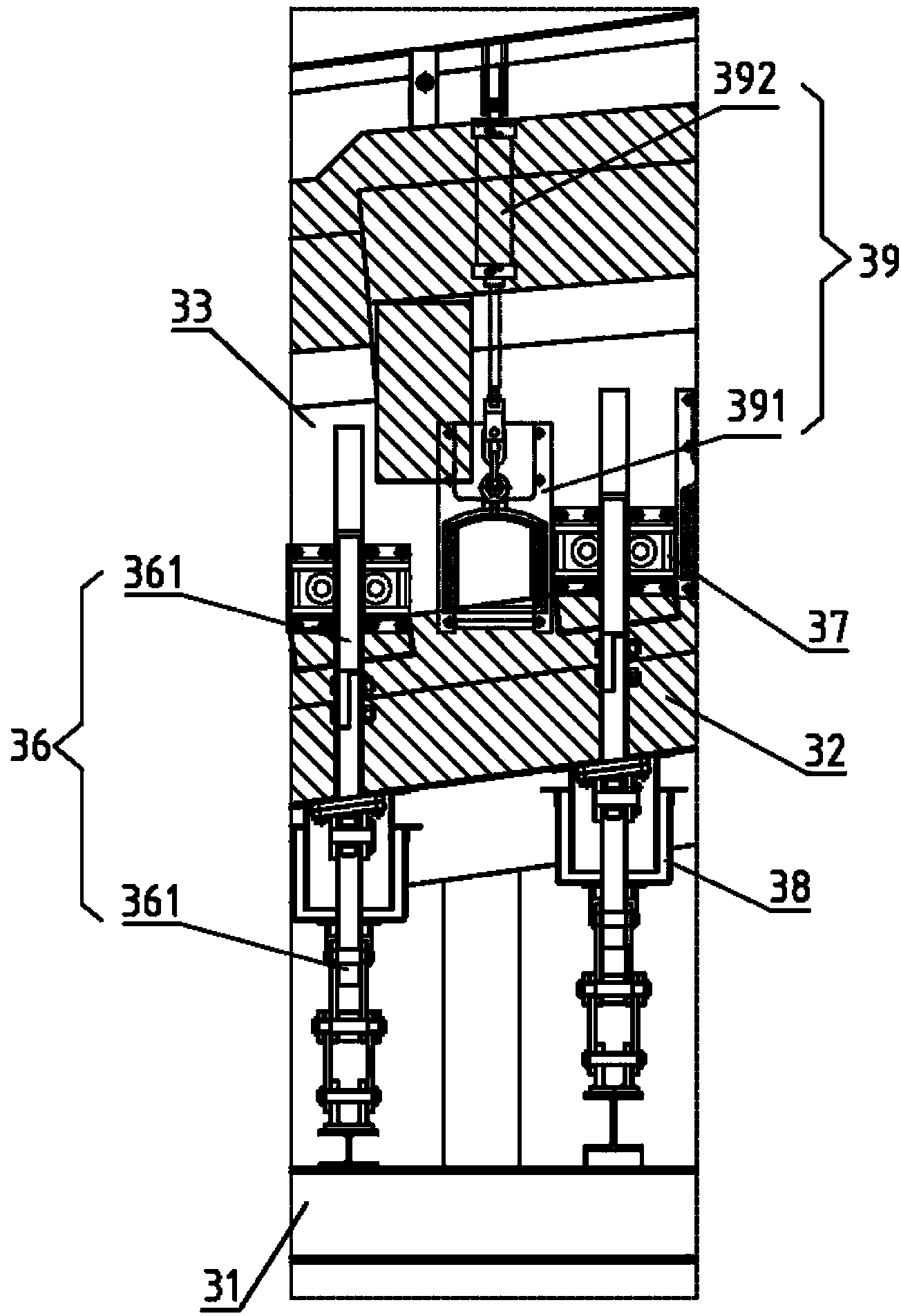

[0018] See figure 1 , The present invention provides a steel ball reheating furnace production line, including: a feeding conveyor 10, a reheating furnace 30, and a discharge conveyor 40; the reheating furnace 30 includes a furnace body bracket 31, and a countertop of the furnace body bracket 31 It is arranged obliquely with respect to the horizontal plane, and a furnace body 32 is provided on the table of the furnace body bracket 31, and the furnace body 32 is a masonry made of thermal insulation materials. The furnace body 32 is provided with a heating chamber 33, one end of the heating chamber 33 (the end with a higher height relative to the horizontal plane) is provided with a steel ball inlet 34, and the feeding conveyor 10 is connected to the steel ball inlet 34; the heating chamber A steel ball discharge port 35 is provided at the other end of 33, and the dis...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap