A high-temperature speckle fabrication method based on plasma spraying

A production method and plasma technology, applied in coating, fusion spraying, metal material coating process, etc., can solve problems such as inability to perform correlation calculation, decrease in bonding force, image failure, etc., and achieve high flexibility and thermal deformation. Small, high-quality sprayed surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

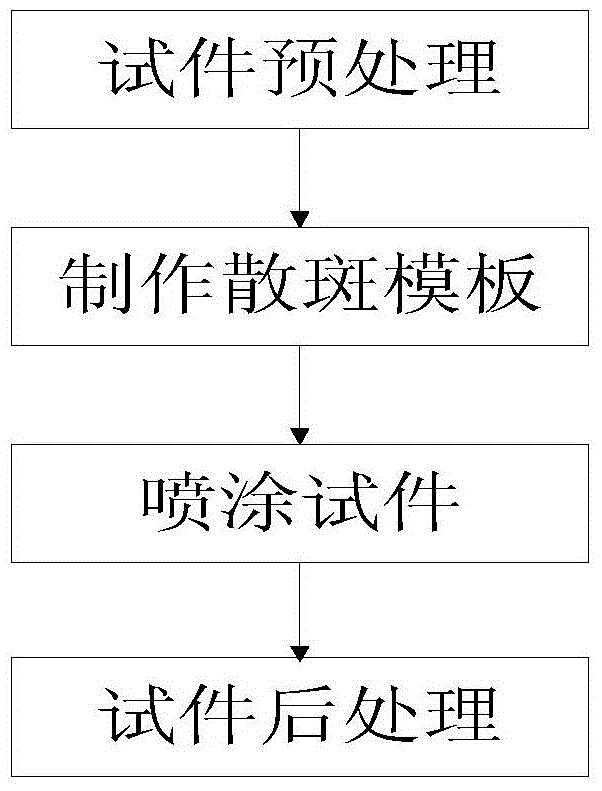

[0021] In one embodiment, a high-temperature speckle production method based on plasma spraying, the method includes the following steps:

[0022] Step 1: Specimen pretreatment: choose different pretreatment methods according to the strain of the material; among them, for the specimens with a strain greater than or equal to 30%, the purification treatment is carried out after roughening treatment, and for the specimens with a strain less than 30% Parts are purified;

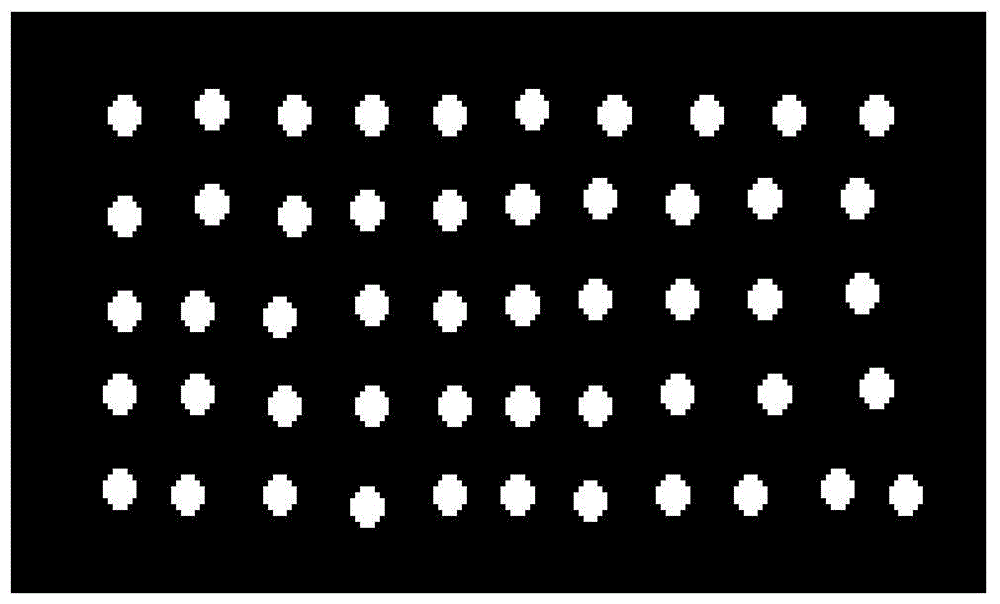

[0023] Step 2: Make a spray template: make a spray template that completely covers the test piece according to the size of the test piece;

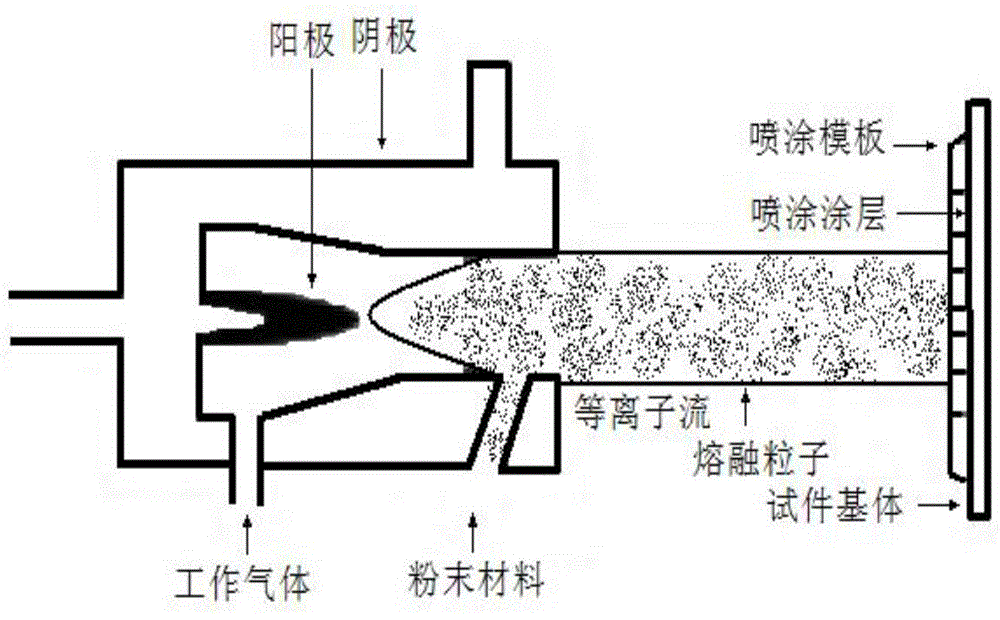

[0024] Step 3: Spray the test piece: use the prepared spray template to wrap the pretreated test piece tightly, and use the plasma spraying process to spray the test piece;

[0025] Step 4: Post-treatment of the test piece: After the spraying is completed, the sprayed test piece is cooled.

[0026] In this embodiment, the pretreatment of the specimen is an important part o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com