Sealing performance inspecting device for flange assembly

An inspection device and sealing technology, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, and by measuring the increase and deceleration rate of fluid, can solve problems such as troublesome operation, deviation of inspection results, and unguaranteed inspection accuracy, etc., to achieve The effect of improving the inspection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

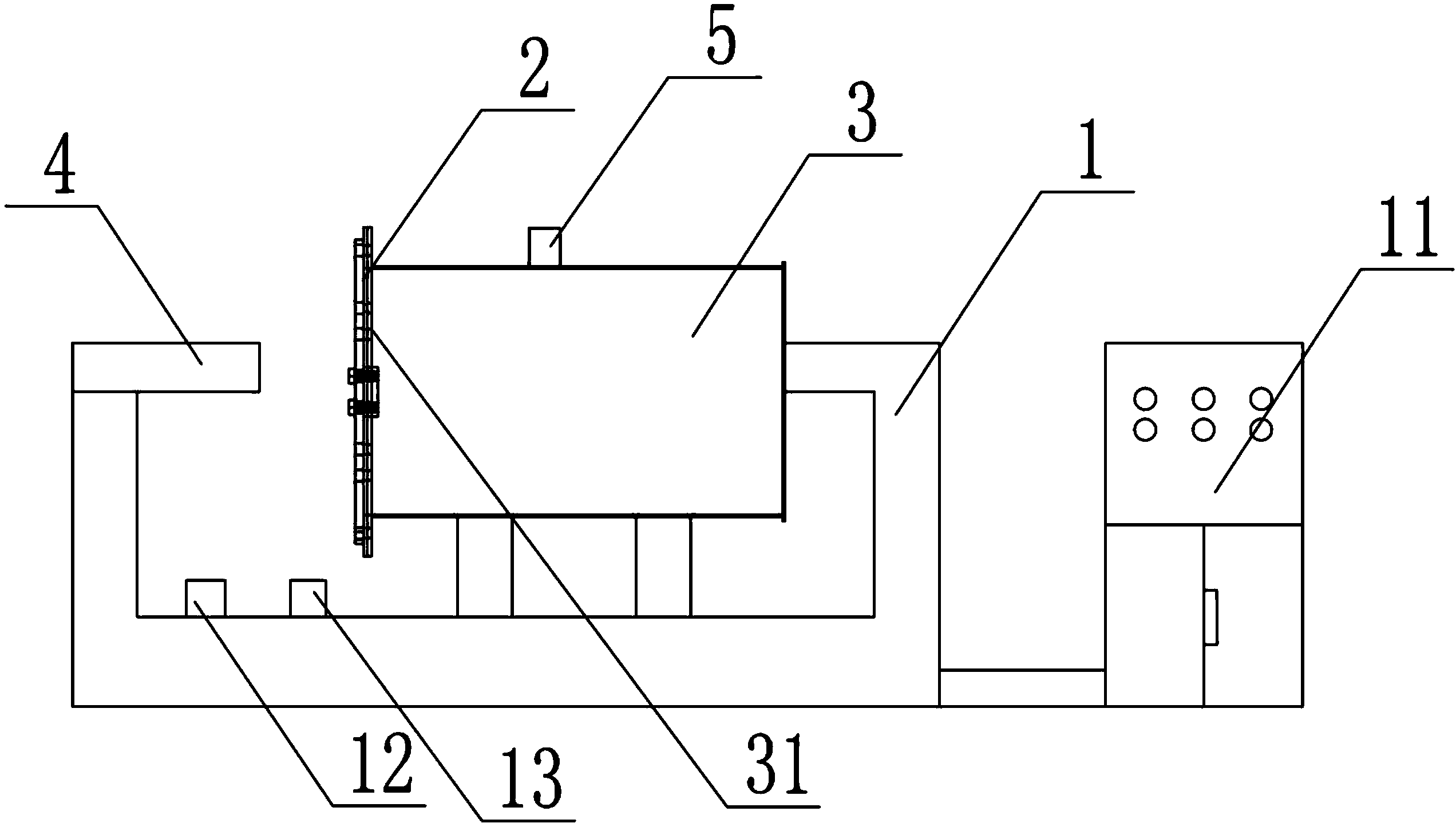

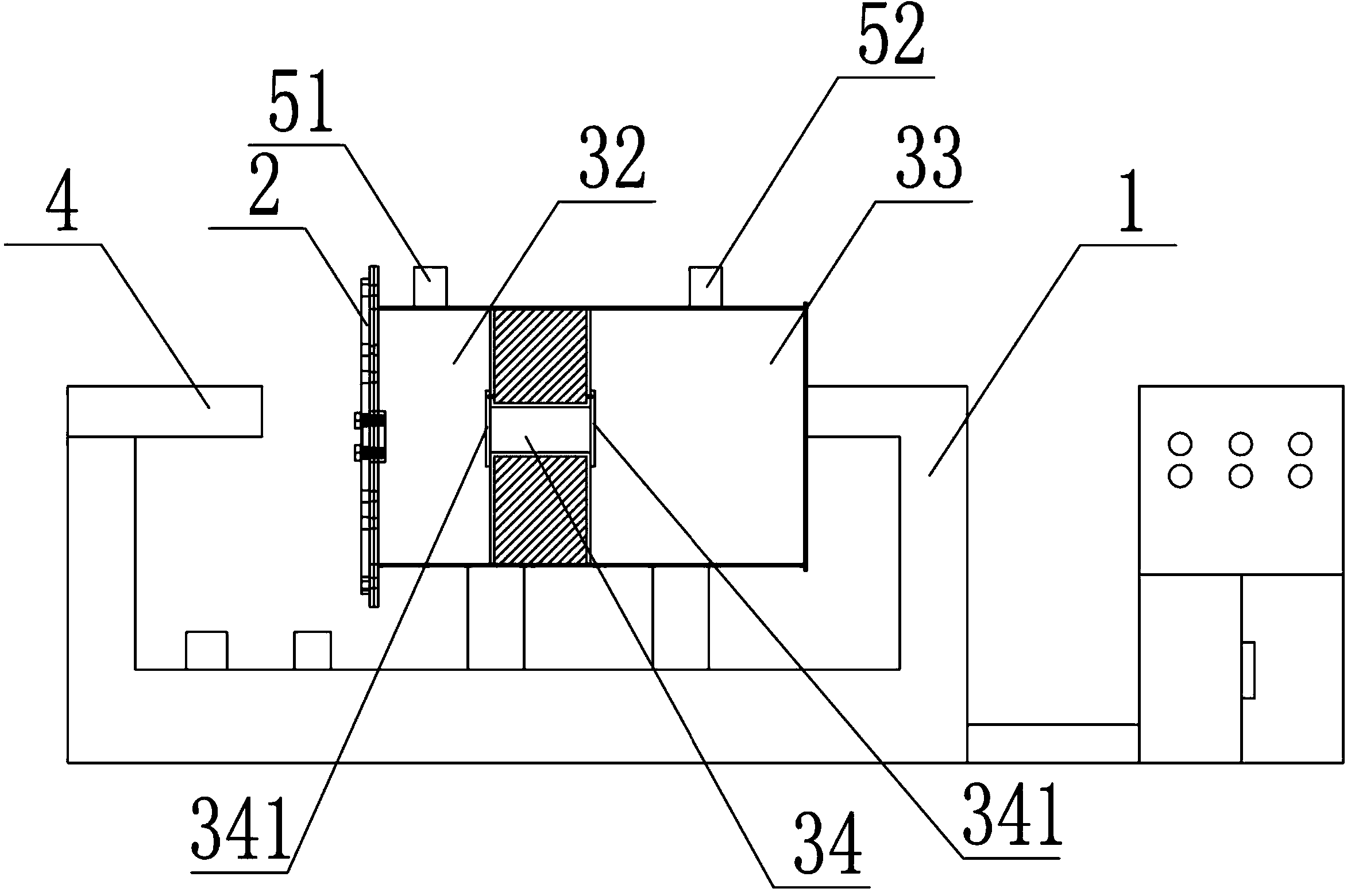

[0033] In order to achieve the purpose of the present invention, as figure 1 As shown, in some embodiments of the sealing inspection device for flange assembly of the present invention, it includes: a cavity 3, which has an opening 31, and the flange assembly 2 passes through the flange assembly 2 during inspection. The hole is fixedly arranged on the opening 31 in other ways such as self-positioning or clamping, and the cavity 3 is also connected to an air source (not shown); the driving unit 4 is arranged at the opening 31, and the driving unit 4 passes through it during inspection. The power output shaft presses the flange assembly 2 from the outside of the cavity 3; the pressure gauge 5 is installed in the cavity 3 and detects the pressure in the cavity 3.

[0034] Such as figure 1 As shown, in order to form a more stable installation s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com