Glass softening point testing device

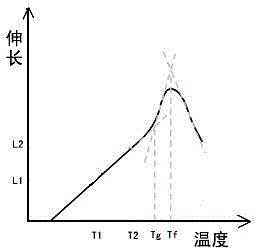

A glass softening point and testing device technology, applied in the investigation phase/state change and other directions, can solve the problem of lack of optical fiber drawing process and the inability to obtain the sample length accurately, and achieve the effect of simple and cheap device operation and accurate data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

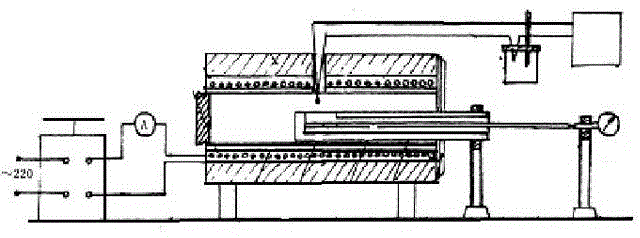

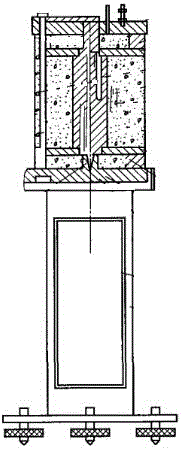

[0019] The softening point testing device described in the technical solution of the present invention is as Figure 4 As shown, it is mainly composed of a heating furnace 6, an upper protective cover 4, a lower protective cover 5, a sample support 9, a test pressure bar 11 and a load 1, and the sample support 9 is located at the bottom of the lower protective cover 5, and the test sample 10 is placed on top of the sample holder 9. The sample 10 to be tested is located in the middle of the heating furnace 6 , and the temperature measuring thermocouple 7 is placed in the sample holder 9 at the bottom of the sample 10 to be tested. And the upper protective cover 4, the lower protective cover 5, the sample holder 9 and the test pressure rod 11 are made of quartz material or zero-expansion glass material, so that the lower thermal expansion coefficient qua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com