A kind of preparation method of ditetraethylammonium decahydrodecaborate

A technology of bistetraethylammonium and decahydrodecaboric acid is applied in chemical instruments and methods, compounds containing elements of Group 3/13 of the periodic table, organic chemistry, etc., and can solve the problems of low product yield and long reaction time, etc. problems, to achieve the effect of simplifying the reaction steps, improving the catalytic activity, and facilitating the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

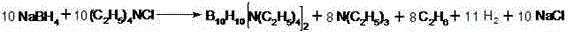

Image

Examples

Embodiment 1

[0015] Add 34g of sodium borohydride, 166g of tetraethylammonium chloride, 0.2g of Ni and alumina composite catalyst, 50g of deionized water, and 332g of paraffin oil in sequence in the microwave reactor with exhaust gas absorption. 300W microwave irradiation for 50s, then 800W microwave irradiation at 175~180°C for 1 hour, then take out the reaction mixture, disperse with 664g petroleum ether, filter, add 500g of acetonitrile to the filter cake, heat and reflux at 80~85°C for 1 hour and then cool Filtrate, evaporate the filtrate to dryness, then add 100g of methanol with a volume percentage of 85%, heat and reflux at 65~70°C for half an hour, then heat filter, cool the filtrate, and filter at room temperature to obtain a white crystalline ditetraethylammonium decahydrodecaborate product 34.6 g (91.5% yield). (For NMR boron spectrum, see figure 1 ). The mass ratio of Ni and alumina is 1:1.

Embodiment 2

[0017] Add 24g of sodium borohydride, 83g of tetraethylammonium chloride, 0.2g of Cu and magnesium oxide composite catalyst, 33g of deionized water, and 240g of paraffin oil in sequence in the microwave reactor with tail gas absorption. 300W microwave irradiation for 60s, then 800W microwave irradiation at 175~180°C for 50min, then take out the reaction mixture, filter it with 480g petroleum ether, add 400g acetonitrile to the filter cake, heat and reflux at 80~85°C for 1 hour, then cool and filter. After the filtrate was evaporated to dryness, 100 g of 85% methanol was added, heated and refluxed at 65 to 70° C. for half an hour, then heated and filtered, the filtrate was cooled, and filtered at room temperature to obtain 17.1 g of a white crystalline ditetraethylammonium decahydrodecaborate product (yield 90.5%). The mass ratio of Cu and magnesium oxide is 1:2. (For NMR boron spectrum, see figure 1 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com