A kind of explosion-proof screw and the processing technology of this explosion-proof screw

A processing technology and screw technology are applied in the field of explosion-proof screws and the processing technology of the explosion-proof screws, which can solve the problems of being unsuitable for mass production and low production efficiency, and achieve the effects of reducing labor costs and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

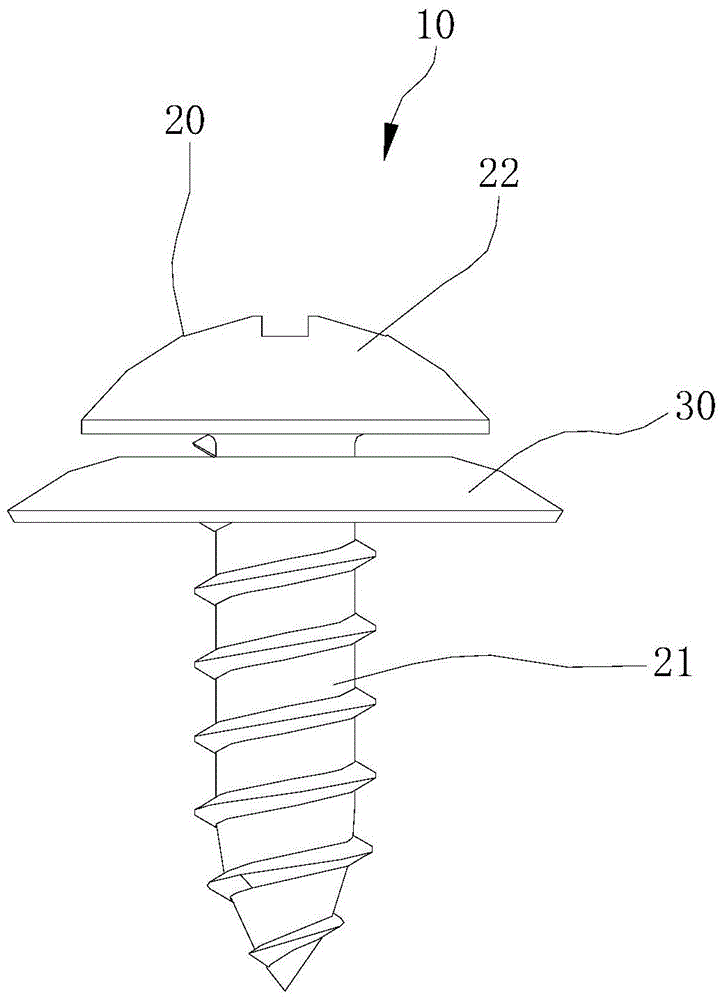

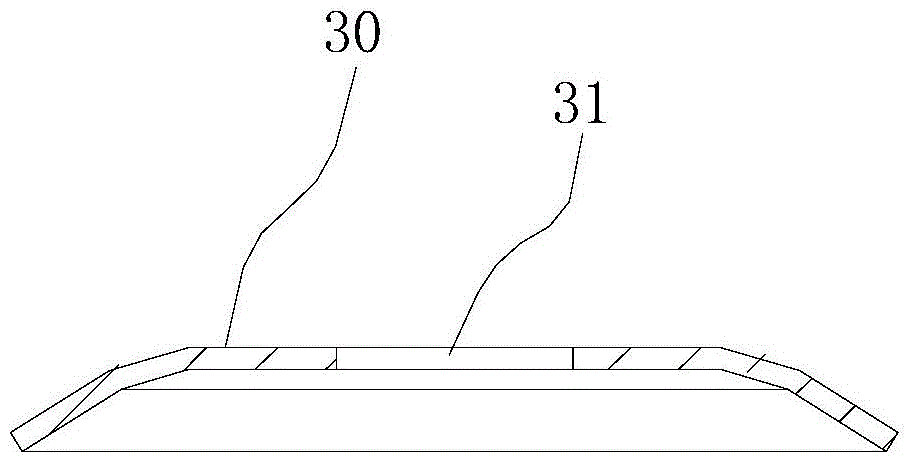

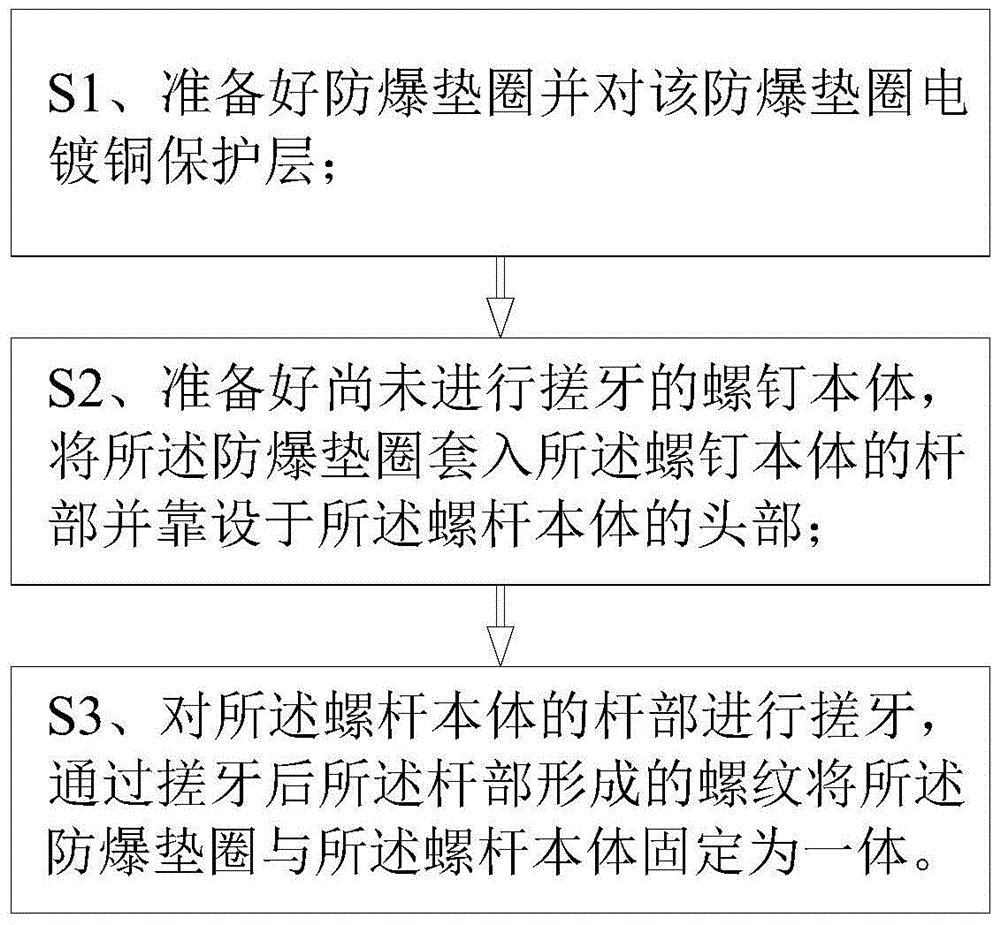

[0023] see figure 1 As shown, the present invention provides an explosion-proof screw 10, including a screw body 20, the screw body 20 includes a stem 21 and a head 22 positioned at the upper end of the stem 21, and the explosion-proof screw 10 also includes an explosion-proof gasket 30, wherein, in this case The selected explosion-proof washer 30 has a better cushioning function than ordinary flat washers, elastic washers, and external-toothed washers; It is fixed with the screw body 20 as a whole by the threads formed after rubbing the teeth on the rod portion 21 . When the explosion-proof s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com