Hub suspension assembly for spray coating line

A technology of suspension components and spraying lines, applied in the direction of spraying devices, etc., can solve the problems of low production efficiency and spraying material utilization rate, and achieve the effects of improving material utilization rate and production efficiency, increasing conveying volume, and convenient operation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0009] In the following, the present invention will be further explained through the embodiments and the accompanying drawings:

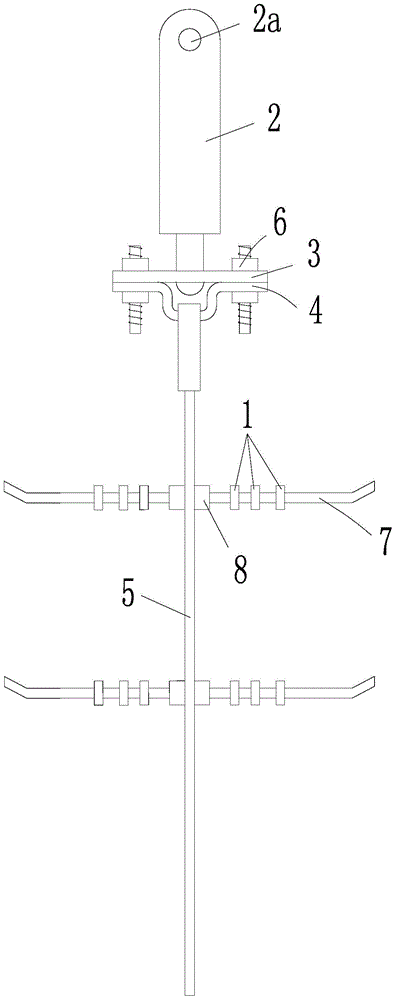

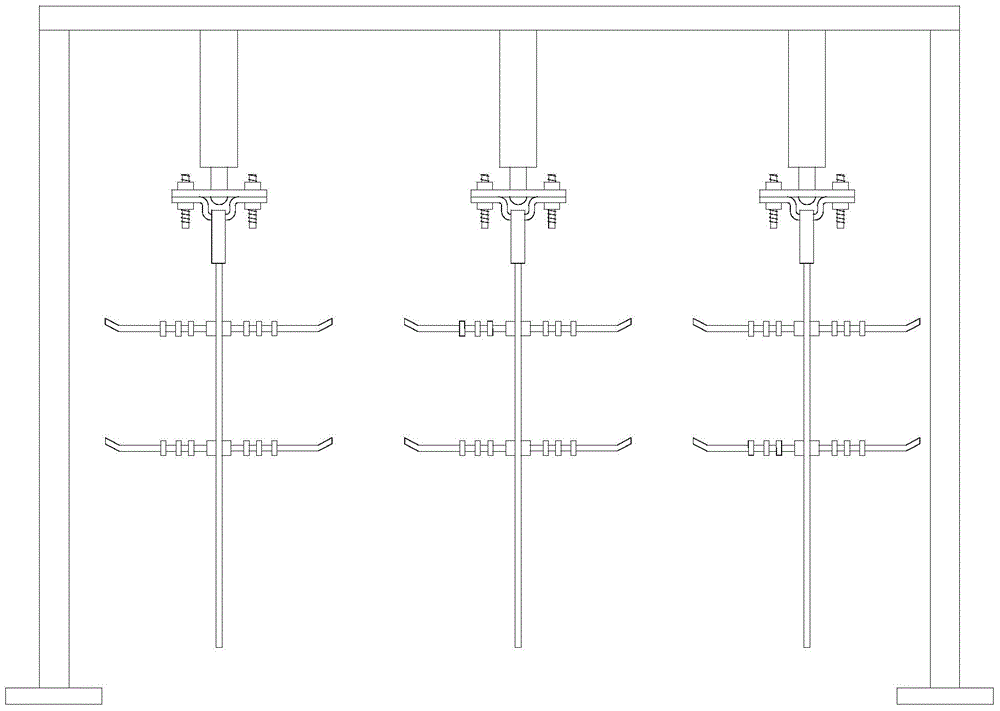

[0010] Such as figure 1 The illustrated wheel hub suspension assembly for the spraying line includes an upper connecting rod 2, a horizontal connecting plate 3, a "U"-shaped connecting plate 4, and a suspension main rod 5 that are sequentially connected from top to bottom. The upper end of the upper connecting rod 2 is provided with a suspension hole 2a connected to the circulating conveyor chain. The lower end of the upper connecting rod 2 and the middle part of the horizontal connecting plate 3 are movably riveted together, and the horizontal connecting plate 3 can rotate freely around the axis. The top of the suspension main rod 5 is provided with a suspension hole and is hung on the middle of the “U”-shaped connecting plate 4 through the suspension hole. The horizontal connecting plate 3 and the “U”-shaped connecting plate 4 are fastened together by...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap