Automobile shock absorber hose support welding device

A technology for automobile shock absorbers and welding devices, applied in auxiliary devices, welding equipment, welding equipment, etc., can solve problems such as hindering the work of springs, and achieve the effects of easy operation, simple structure, and precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

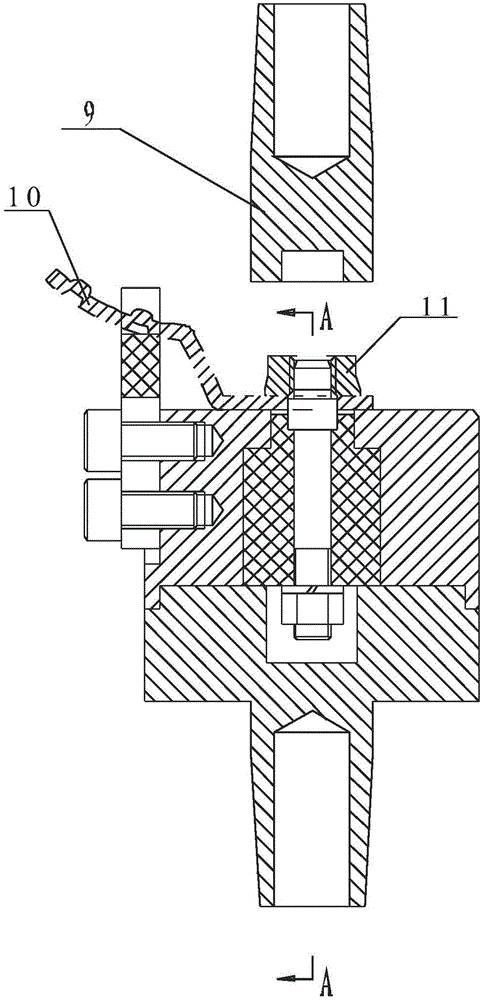

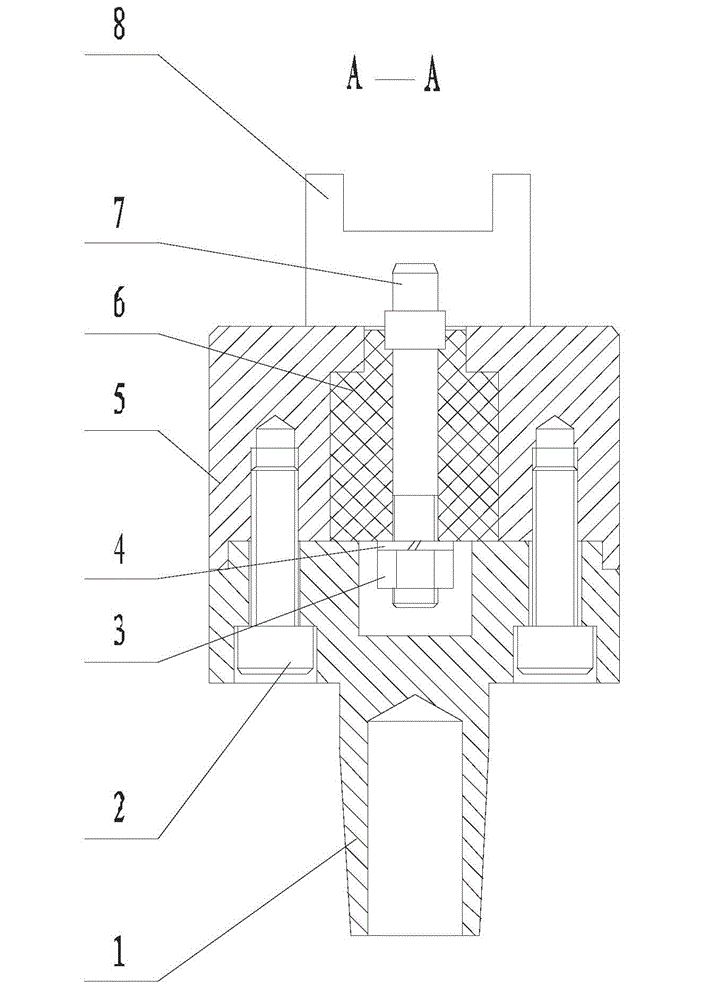

[0013] like figure 1 , 2 Shown is an automobile shock absorber hose bracket welding device, including a positioning seat 5, an insulating sleeve 6 with the same height as the positioning seat 5 is arranged in the middle of the positioning seat 5, and the middle of the insulating sleeve 6 is installed There is a vertical positioning column 7; the lower end of the positioning column 7 is fastened with the bottom surface of the positioning seat 5 by a nut 3, and a gasket 4 is installed at the connection between the nut 3 and the positioning seat 5; the positioning column The upper end of 7 is higher than the end of the insulating sleeve 6 and has a positioning hole; the bottom of the positioning seat 5 is provided with a lower electrode 1, and the lower electrode 1 is fastened to the positioning seat 5 by screws 2; An upper electrode 9 is provided directly above the upper end of the positioning column 7 .

[0014] Furthermore, in order to make the hose bracket 10 more precisely...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap