A kind of manufacturing method of new round tube tower

A manufacturing method and a technology of round tube towers, which are applied in the field of manufacturing new round tube towers, can solve the problems of inability to achieve batch intercombination, beautiful appearance, small manufacturing error, and simple manufacturing method, so as to achieve batch intermatching and beautiful appearance , the effect of simple production method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

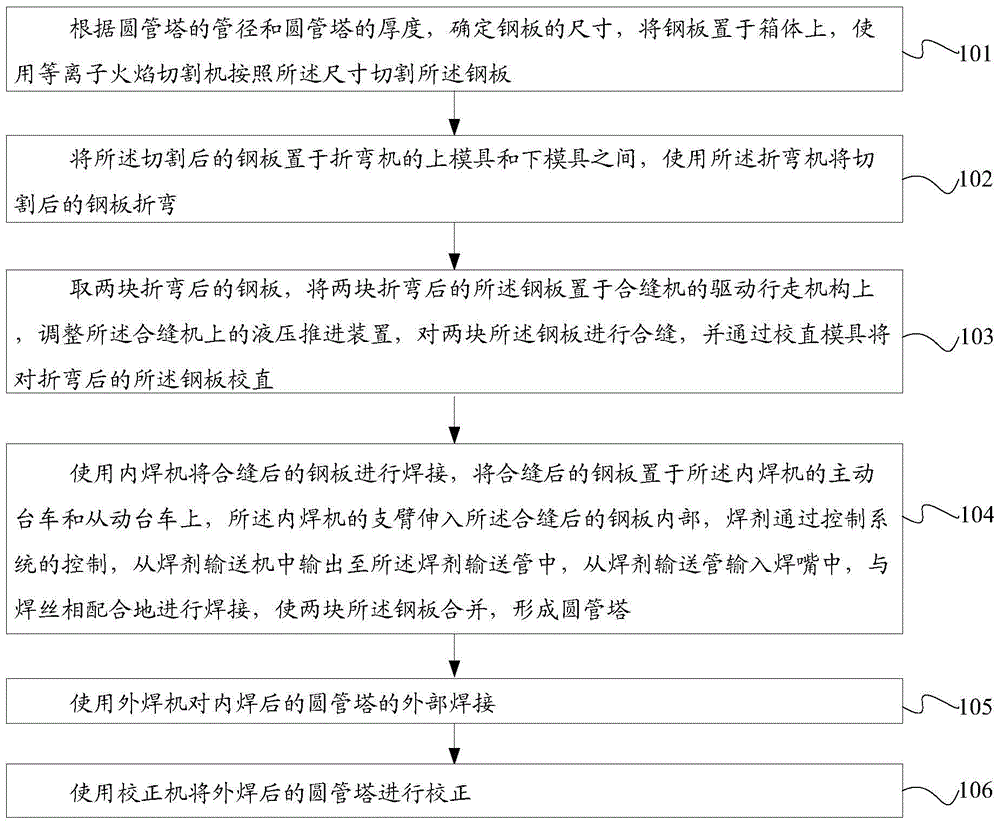

[0037] Such as figure 1 Shown, be the manufacture method of a kind of novel circular tube tower described in the present embodiment 1, comprising:

[0038] Step 101, cutting: Determine the size of the steel plate according to the pipe diameter of the circular tube tower and the thickness of the circular tube tower, place the steel plate on the box body, and cut the steel plate according to the size by using a plasma flame cutting machine.

[0039] Specifically, the cutting speed of the plasma flame cutting machine is 5 m / min, and the cutting nozzle height of the plasma flame cutting machine is 4 mm.

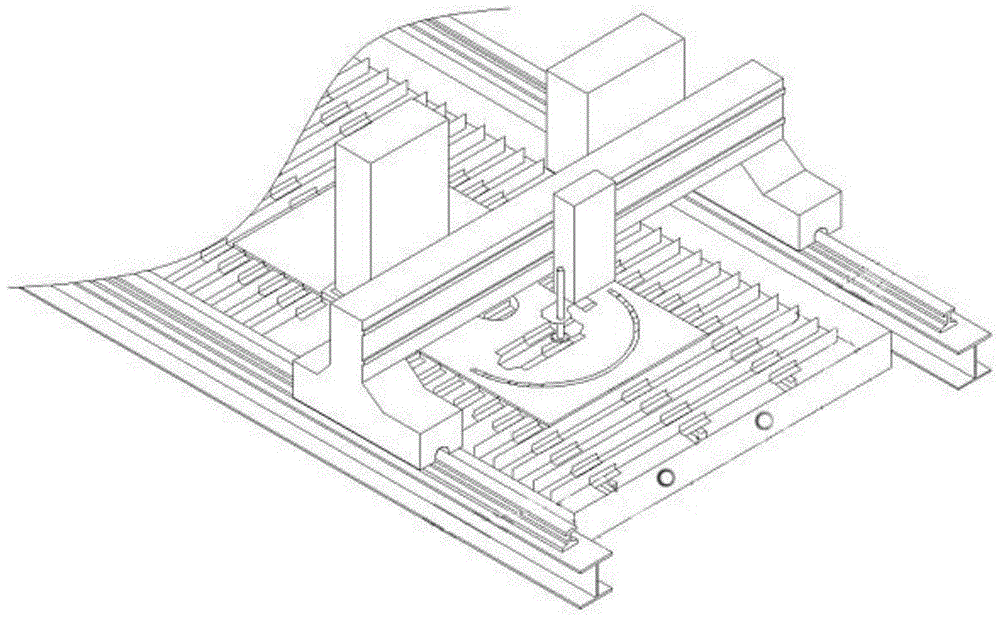

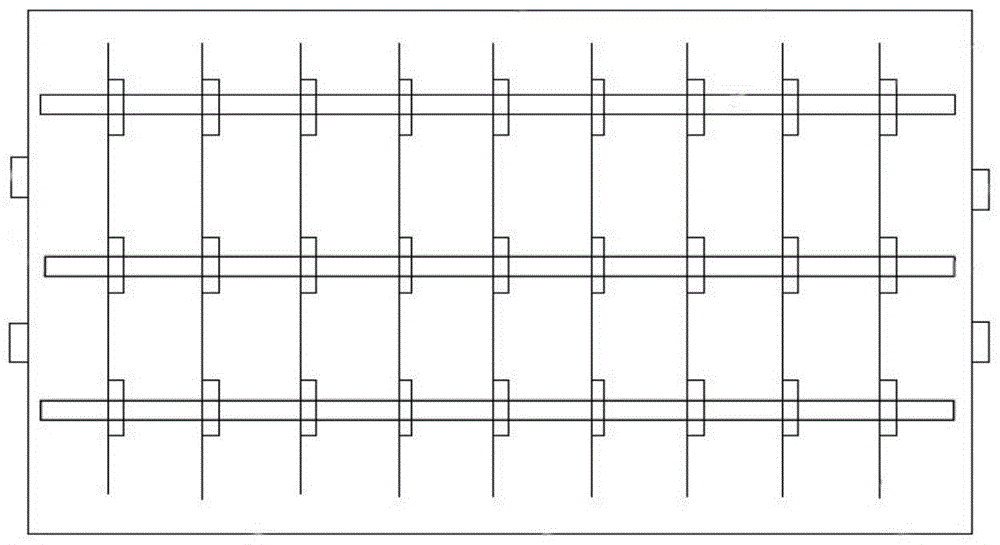

[0040] Specifically, such as figure 2 As shown, it is the plasma torch cutting machine described in Embodiment 1, the bottom of the plasma torch cutting machine is provided with a box, and the steel plate is placed on the box, as image 3 As shown, it is the box body applied to the plasma flame cutting machine described in this embodiment 1. The shape of the supporting parts i...

Embodiment 2

[0054] Such as figure 1 Shown, be the manufacture method of a kind of novel circular tube tower described in this embodiment 2, comprising:

[0055] Step 101, cutting: Determine the size of the steel plate according to the pipe diameter of the circular tube tower and the thickness of the circular tube tower, place the steel plate on the box body, and cut the steel plate according to the size by using a plasma flame cutting machine.

[0056] Specifically, the cutting speed of the plasma flame cutting machine is 8m / min, and the cutting nozzle height of the plasma flame cutting machine is 5mm.

[0057] Specifically, such as figure 2 As shown, it is the plasma torch cutting machine described in Embodiment 1, the bottom of the plasma torch cutting machine is provided with a box, and the steel plate is placed on the box, as image 3 As shown, it is the box body applied to the plasma flame cutting machine described in this embodiment 1. The shape of the supporting parts inside the...

Embodiment 3

[0072] Such as figure 1 Shown, be the manufacture method of a kind of novel circular tube tower described in this embodiment 3, comprising:

[0073] Step 101, cutting: Determine the size of the steel plate according to the pipe diameter of the circular tube tower and the thickness of the circular tube tower, place the steel plate on the box body, and cut the steel plate according to the size by using a plasma flame cutting machine.

[0074] Specifically, the cutting speed of the plasma flame cutting machine is 10 m / min, and the cutting nozzle height of the plasma flame cutting machine is 6 mm.

[0075] Specifically, such as figure 2 As shown, it is the plasma torch cutting machine described in Embodiment 1, the bottom of the plasma torch cutting machine is provided with a box, and the steel plate is placed on the box, as image 3 As shown, it is the box body applied to the plasma flame cutting machine described in this embodiment 1. The shape of the supporting parts inside ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com